Vacuum flash evaporation enhanced mass transfer deoxidation equipment and deoxidation process

A flash evaporation and vacuum technology, applied in the field of water deoxygenation, can solve the problems of narrow application range, large steam consumption, small amount of water steam, etc., and achieve the effects of wide application range, low operating cost and short residence time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

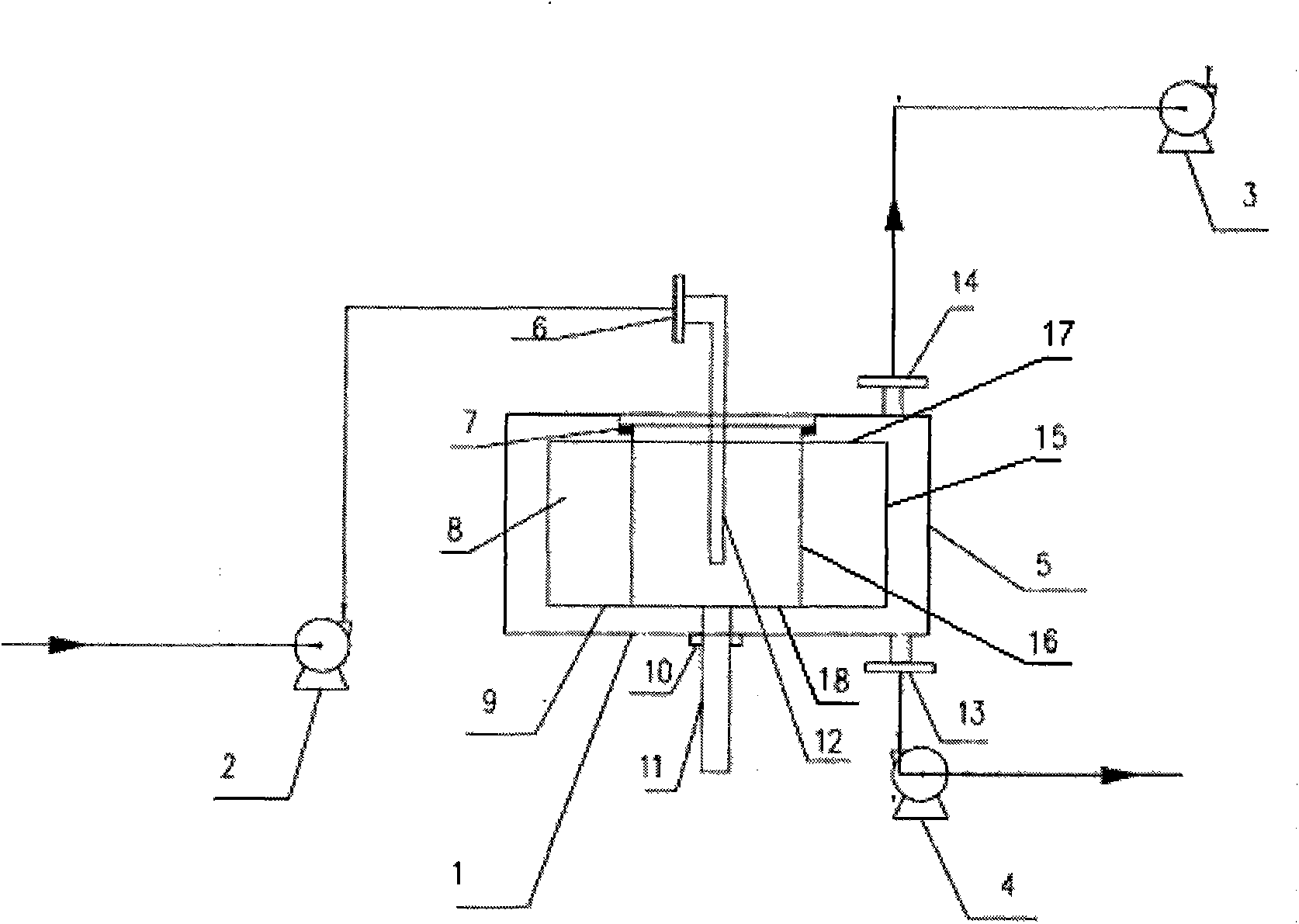

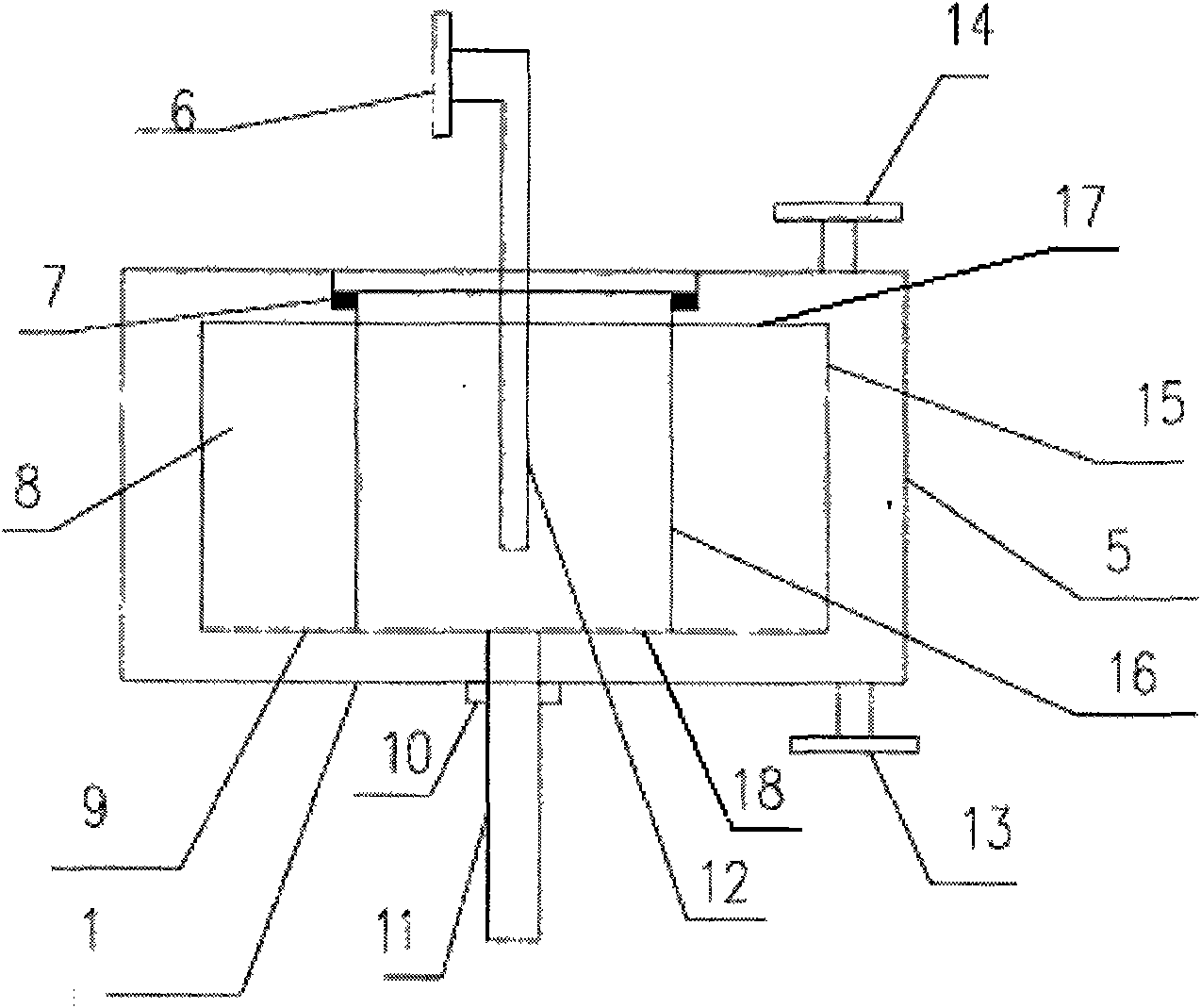

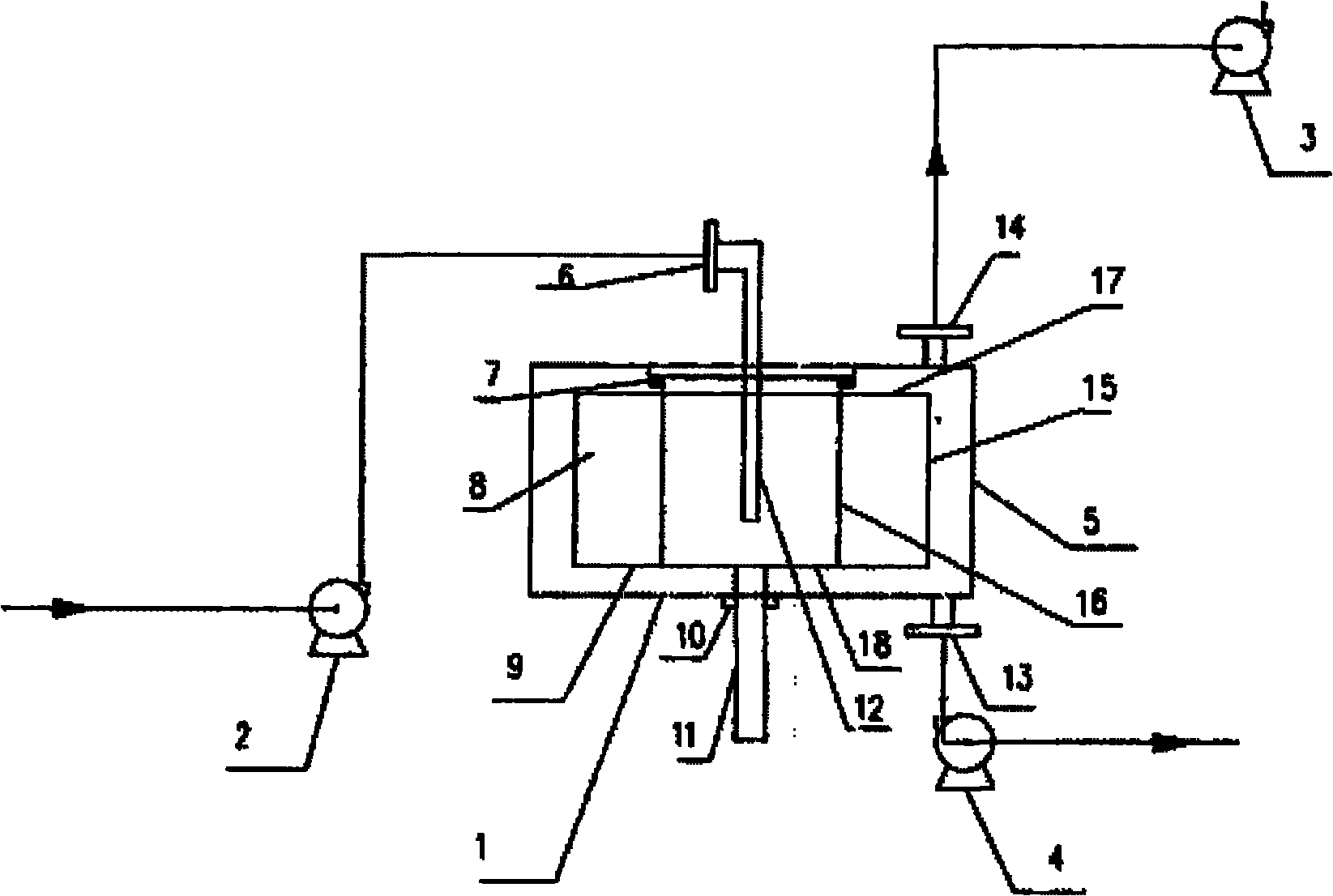

[0038] Such as figure 1 As shown, a vacuum flash enhanced mass transfer deoxidation equipment, including:

[0039] An enhanced mass transfer deoxidizer 1, the enhanced mass transfer deoxidizer 1 includes a cylindrical shell 5; the shaft 11 passing through the center of the bottom of the shell 5 is mechanically sealed with the bottom of the shell 5; the cylindrical shell 5 contains A rotating drum 9 that can rotate at a high speed, the drum includes a circular bottom plate 18, an outer sleeve 15, an inner sleeve 16 and an annular upper plate 17, the center of the bottom plate 18 is connected with the shaft 11, the outer sleeve 15 and the inner sleeve The sleeves 16 are all porous plate structures, and the packing layer 8 is arranged therebetween; the upper end of the enhanced mass transfer deoxidizer 1 is provided with a spray pipe 12, and one end of the spray pipe is a feed inlet 6, and the upper end of the drum inner sleeve 16 is The horizontal protruding part 7 is arranged ...

Embodiment 2

[0049] Under the action of the water ring vacuum pump 3, the pressure of the enhanced mass transfer deoxidizer 1 drops to 12.34KPa, and the pressure of the drum outer cylinder wall 15 is equivalent to it. At this time, the boiling point of water is 50 degrees, and due to the stainless steel mesh packing layer 8 The pressure drop is 7.59KPa, so the pressure of the drum inner cylinder 16 is 19.93KPa. Oxygenated water heated to 60°C enters the enhanced mass transfer deaerator 1 from the feed pump 2, enters from the feed port 6, sprays into the inner cylinder wall 16 of the drum through the spray pipe 12 and enters the packing layer 8, the pressure When the saturated vapor pressure drops to 19.93KPa at 60°C, the water starts to boil and generate steam; the shaft 11 is directly connected to the speed regulating motor, and the packing 8 placed in the drum 9 is driven by the shaft 11 to rotate at a high speed, and its speed range is 500 ~2000rpm, beat water into liquid film or drople...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com