Modified polyester and water-borne middle coating composition

A technology of modifying polyester and polyester, applied in the coating and other directions, can solve the problems of poor impact resistance and low gloss, and achieve the effects of good water resistance, good stone resistance and excellent stone resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

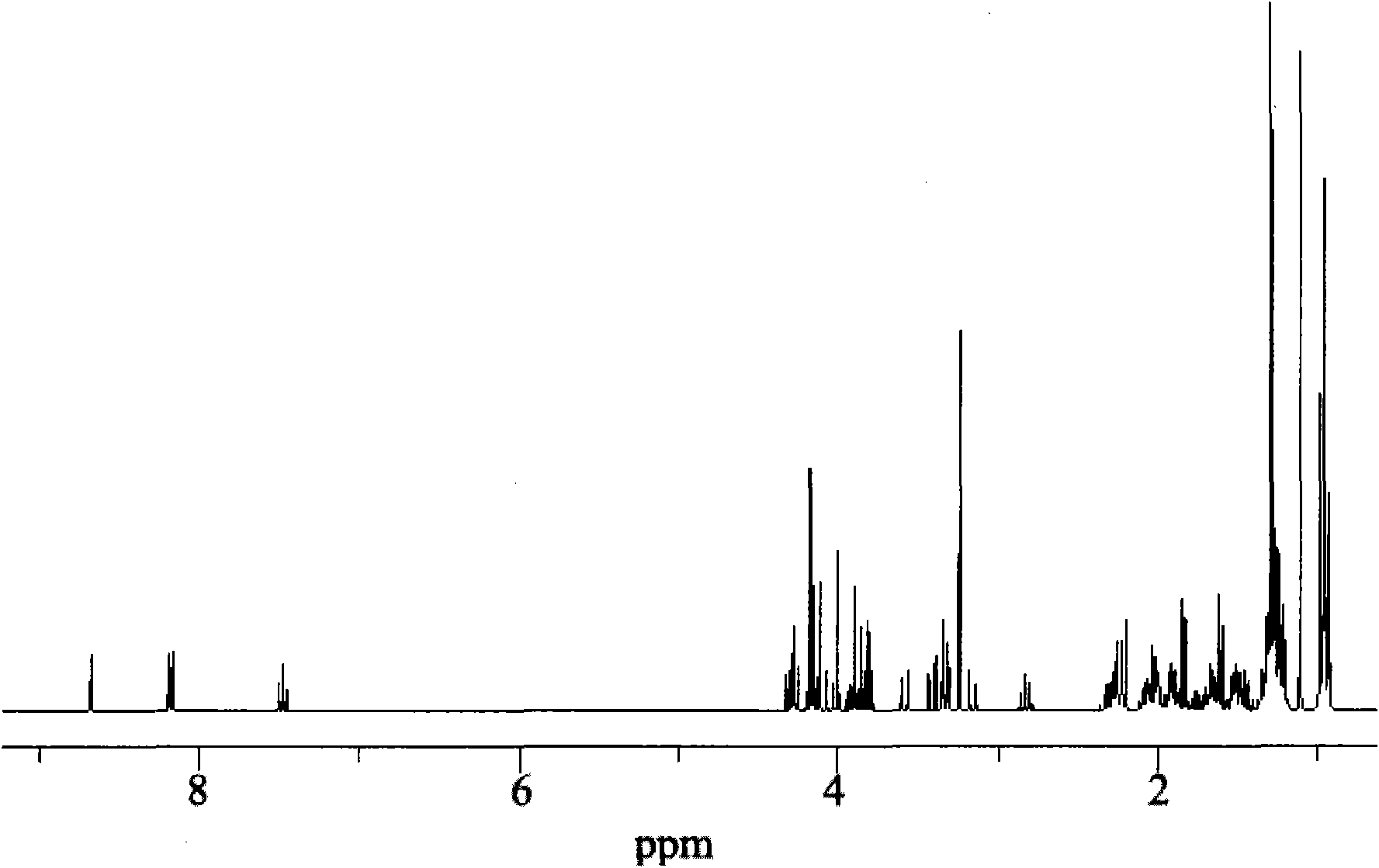

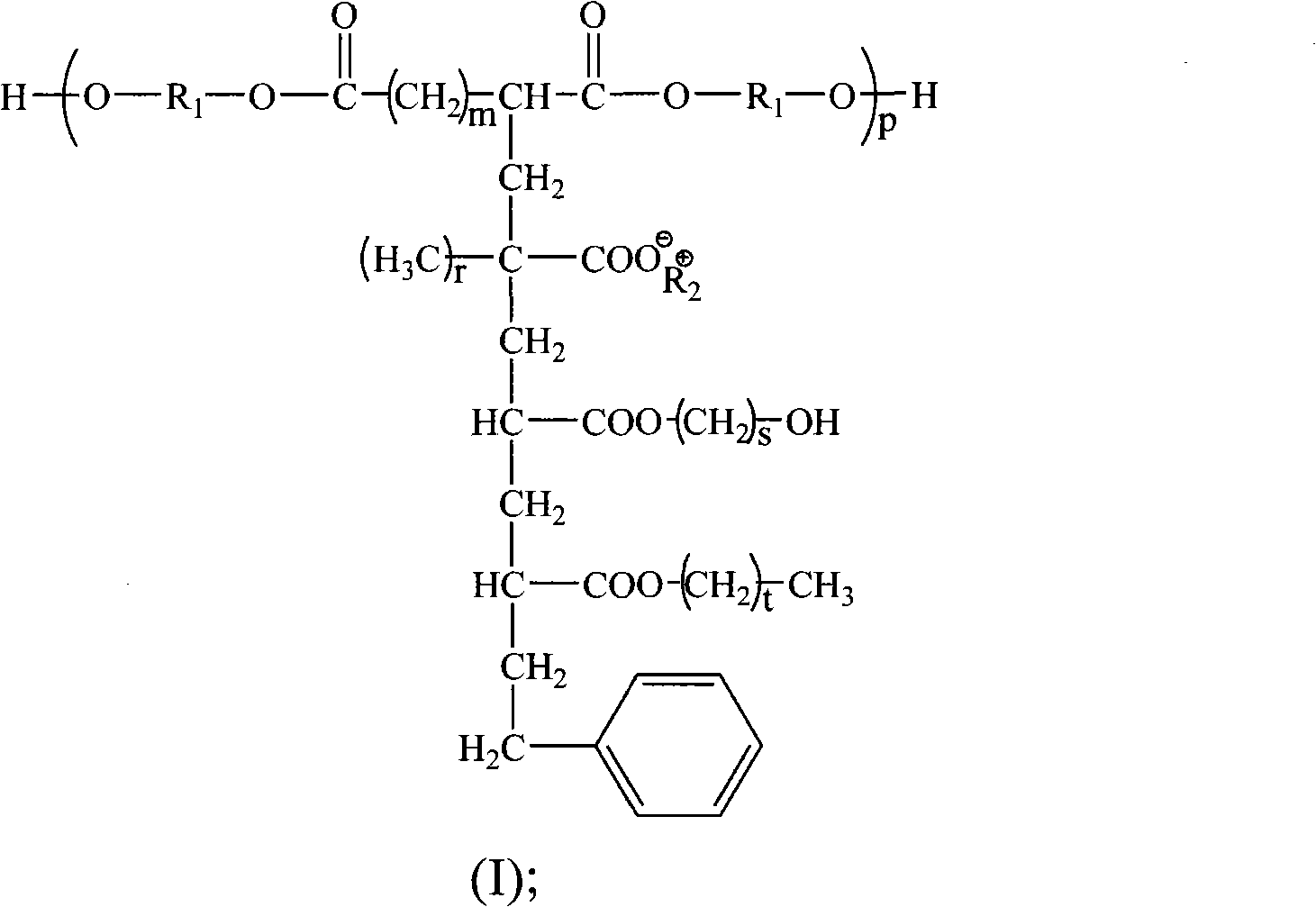

Image

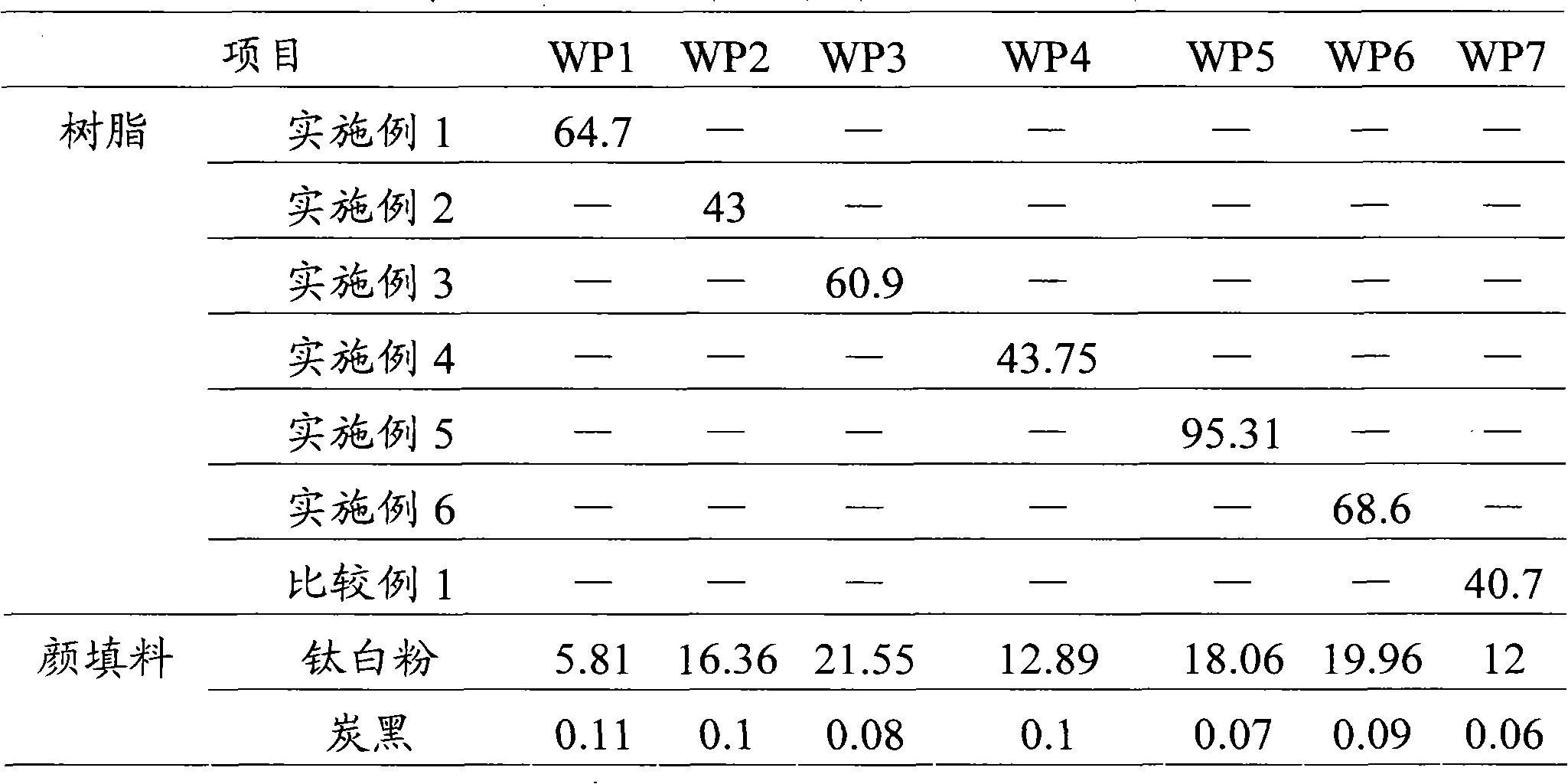

Examples

Embodiment 1

[0084] Add 138g neopentyl glycol, 95g 2-butyl-2-ethyl-1,3-propanediol, 30g Tris Methylolpropane, 18g 1,4-cyclohexanedimethanol, 35g fumaric acid, 52g glutaconic acid, 206g isophthalic acid, 30g 1,4-cyclohexanedicarboxylic acid, 0.5g Swiss Ciba The company's model is 1010 antioxidant and 0.4g of stannous chloride. Slowly raise the temperature of the four-necked bottle to 180°C for reflux dehydration, then raise the temperature to 210°C at a rate of 15°C / 30min, keep warm and reflux for 3 hours, and then depressurize for 3 hours , after cooling down to 60°C, add 60g of propylene glycol monobutyl ether and stir for 20min to obtain a polyester mixture;

[0085] Mix 15g of acrylic acid monomer, 8g of methacrylic acid monomer, 7.5g of isooctyl acrylate monomer, 12g of hydroxyethyl acrylate and 2.6g of azobisisobutyronitrile to obtain an acrylate mixture;

[0086] The temperature of the polyester mixture was raised to 130±5° C. under nitrogen protection, and the acrylate mixture was ...

Embodiment 2

[0090] Add 231g of neopentyl glycol, 28g of trimethylolpropane, 46g of 1,4-cyclohexanedimethanol, 58g of Fumaric acid, 39g glutaconic acid, 62g octadecenedioic acid, 210g 1,4-cyclohexanedicarboxylic acid, 70g adipic acid, 10g phthalic anhydride, 0.1g Swiss Ciba Model is the antioxidant of 1010, the model of 0.8g Swiss Ciba Company is the antioxidant of 1076, 0.3g tin protochloride and 0.2g dibutyl tin oxide, the four-necked bottle is slowly heated up to 200 ℃ of reflux dehydration, Then heat up to 210°C at a rate of 15°C / 30min, keep warm and reflux for 3h, then depressurize for 3h, after cooling down to 60°C, add 40g of propylene glycol monobutyl ether and 38g of diethylene glycol monobutyl ether, and stir for 20min to obtain polyester mixture;

[0091] 40g of acrylic acid monomer, 18g of hydroxyethyl acrylate, 16g of hydroxypropyl acrylate, 20g of styrene and 5.1g of benzoyl peroxide were mixed uniformly to obtain an acrylate mixture;

[0092] The temperature of the polyest...

Embodiment 3

[0096] Add 287g neopentyl glycol, 152g 2-butyl-2-ethyl-1,3-propanediol, 23g trans Butenedioic acid, 24g glutaconic acid, 153g isophthalic acid, 300g adipic acid, 0.6g Swiss Ciba company type 1010 antioxidant, 0.2g dibutyltin dilaurate and 0.3g oxychloride Tin, slowly heat up the four-necked bottle to 190°C for reflux dehydration, then heat up to 210°C at a rate of 15°C / 30min, keep warm and reflux for 3h, then depressurize for 3h, after cooling down to 60°C, add 95g of ethylene glycol monobutyl ether , stirred for 20min to obtain a polyester mixture;

[0097] 23g of acrylic acid monomer, 13g of hydroxyethyl acrylate and 2.1g of azobisisobutyronitrile were mixed uniformly to obtain an acrylate mixture;

[0098] The temperature of the polyester mixture was raised to 130±5° C. under nitrogen protection, and the acrylate mixture was added dropwise at a rate of 12 mL / min. After the dropwise addition, the reaction was continued for 3 hours, and then the temperature was lowered to 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com