Lactobacillus reuteri fermented liquid feed, preparation method and application thereof

A technology of Lactobacillus reuteri and liquid feed, applied in biochemical equipment and methods, animal feed, animal feed, etc., can solve the problems of various strains and complicated cultivation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

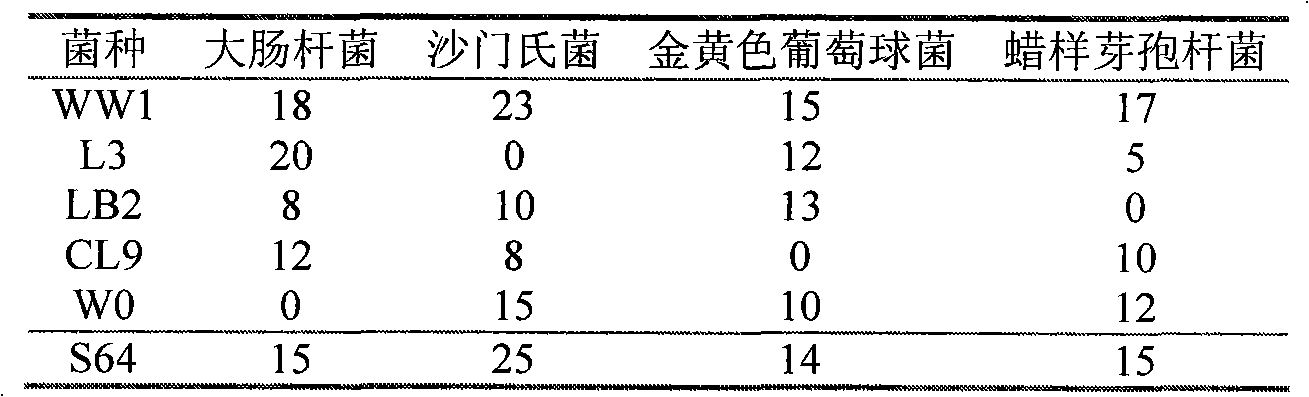

[0060] Embodiment 1: Breeding and strain identification of excellent lactic acid bacteria strains

[0061] (1) Isolation and screening of excellent lactic acid bacteria strains in intestinal contents:

[0062] The contents of the cecum of healthy adult pigs were taken aseptically and diluted appropriately with sterile saline. Dip the diluted solution and inoculate it on the MRS plate medium, culture anaerobically at 37°C for 24 hours, pick colonies with different shapes and colors and inoculate them for pure culture, and perform microscopic examination to observe the color and color of the isolated bacteria. Morphological characteristics.

[0063] Pick the purely cultured Gram-positive non-bacillus bacteria on the plate and inoculate them in MRS liquid medium, and culture them anaerobically at 37°C for 24 hours. Add sterilized glycerol to the bacterial culture solution at a ratio of 20%, mix well, store at -20°C, and set aside. They are respectively numbered CL9, L3, WW1, L...

Embodiment 2

[0090] Embodiment 2: the preparation of Lactobacillus reuteri fermented liquid

[0091] (1) Preparation of Lactobacillus reuteri seed liquid:

[0092] Aseptically inoculate the strains preserved on the slant of the test tube into a 500ml Erlenmeyer flask filled with 400ml of MRS medium, and inoculate them anaerobically at a constant temperature of 30°C for 24h.

[0093] (2) Preparation of Lactobacillus reuteri fermented liquid:

[0094] The Lactobacillus reuteri seed solution prepared above was inoculated into a 50L fermenter equipped with 40L fermentation medium according to the inoculum amount of 5%, and incubated anaerobically at a constant temperature of 40°C for 16h.

[0095] The MRS medium of the present invention is: beef extract 1.0g, tryptone 0.5g, yeast extract powder 0.5g, glucose 1.5g, lactose 0.5g, 5% cysteine 1.0ml, Tween-800.1ml, magnesium chloride 0.05g, 0.2g ferric ammonium citrate, 0.005g manganese sulfate, 0.5g sodium acetate, 1.4g agar powder, 0.2g anhy...

Embodiment 3

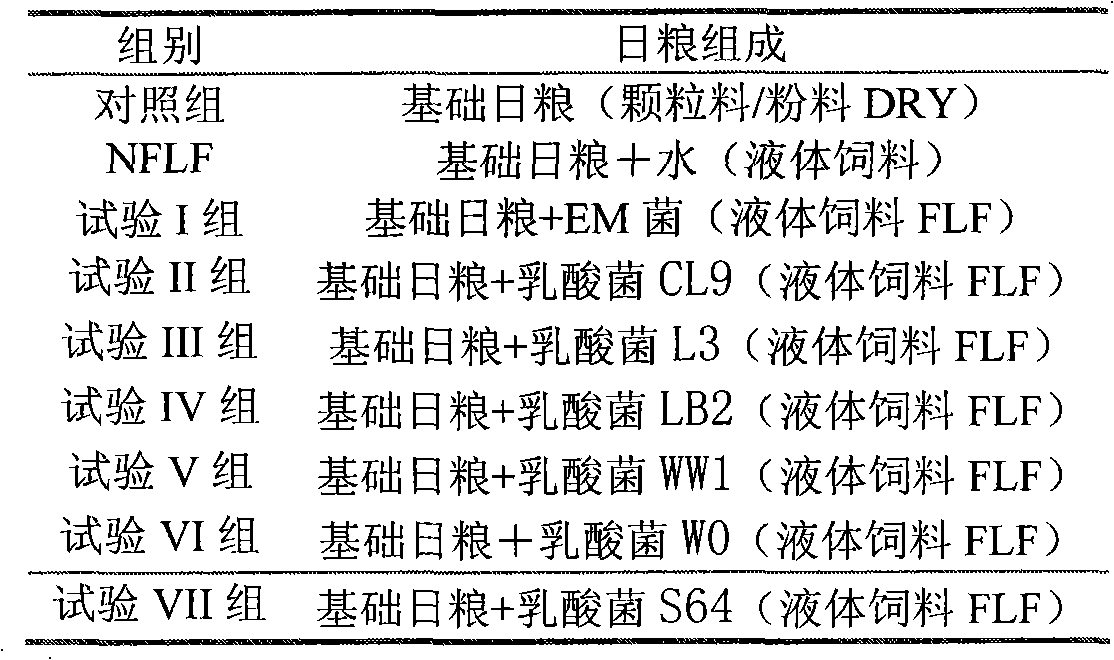

[0097] Embodiment 3, the steps and process parameters of using Lactobacillus reuteri to prepare fermented liquid feed

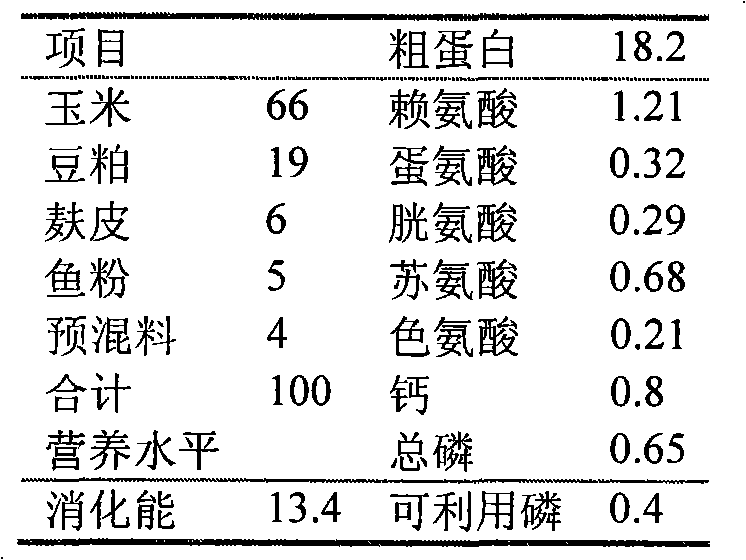

[0098] (1) Preparation of dry matrix for liquid fermentation of Lactobacillus reuteri: the dry matrix for fermentation of Lactobacillus reuteri according to the present invention is an aniseed part of the complete feed, excluding 4% premix The full-price feed is a conventional basal ration formulated with reference to the nutritional needs of pigs in NRC (1998). Namely: mix 66% of corn, 11% of soybean meal, 14% of bran and 5% of fish meal to obtain a dry matrix for fermentation of Lactobacillus reuteri.

[0099] (2) Dilution of bacterial liquid: Inoculate Lactobacillus reuteri fermented liquid in a certain amount of groundwater or tap water container according to the inoculum amount of 1‰, stir evenly, and stand-by, wherein the liquid loading amount of groundwater or tap water is 50 %.

[0100] (3) The process of Lactobacillus reuteri liquid fermented feed:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com