Method for producing succinic acid by Canna edulis ker fermentation

A technology of plantain taro and succinic acid, which is applied in the field of microbial fermentation, can solve the problems of no research reports on the production of succinic acid by fermentation and low yield, etc., and achieve the problem of alleviating the shortage of petrochemical resources, low price and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

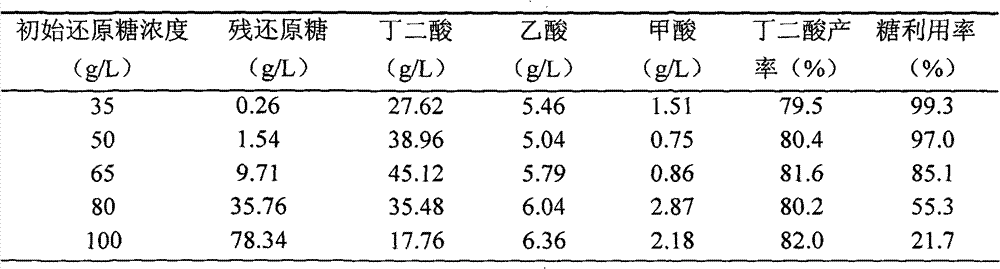

Embodiment 1

[0042] Preparation of plantain taro syrup: Cut plantain tubers into 0.5-5mm thick slices, bake at 40-70°C to below 14% water content (or dry in the sun), and crush to 20-200 mesh; or directly cut fresh plantains The taro tubers are crushed and beaten to obtain fresh plantain taro powder. Soak plantain taro powder or fresh plantain taro powder slurry in water for 2 hours, adjust the pH to 6.7, add amylase (add 20U amylase per gram of plantain taro dry matter), liquefy at 105°C for 30 minutes, then cool to 60°C, adjust pH to 4.5, Add saccharification enzyme (add 300U saccharification enzyme per gram dry matter of plantain taro) for saccharification for 10 hours, filter to obtain plantain taro syrup, it is determined that the syrup contains 15-25% reducing sugar.

[0043] Or soak plantain taro powder or fresh plantain taro powder slurry in water for 1 hour, adjust the pH to 6.5, add amylase (add 10U amylase per gram of plantain taro dry matter), liquefy at 110°C for 20min, then cool...

Embodiment 2

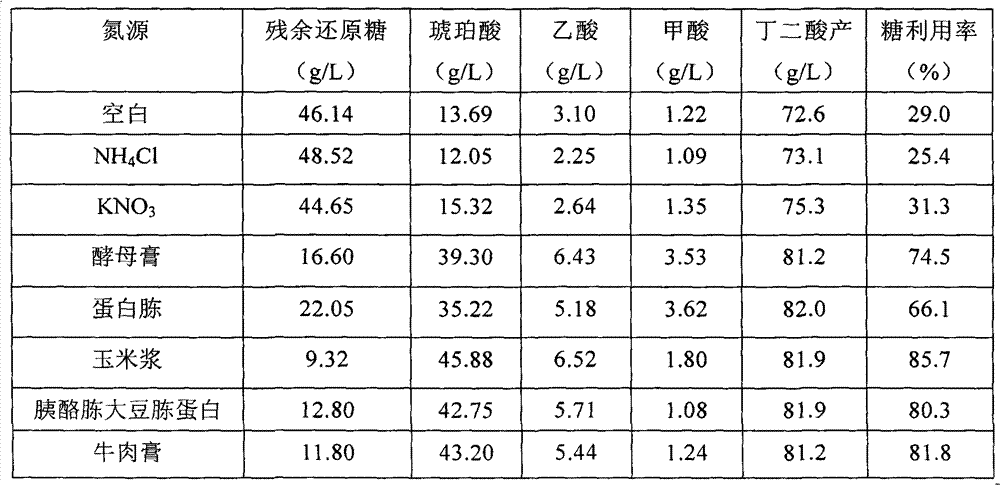

[0052] Take the saccharified plantain taro syrup, the initial reducing sugar concentration is 65g / L, and add different inorganic and organic nitrogen sources (the total nitrogen content is basically equal), and their contents are: blank (no nitrogen source added), NH 4 Cl5.3g / L, KNO 3 9.6g / L, yeast extract 12g / L, peptone 8g / L, corn steep liquor 25g / L, tryptone soy peptone protein 15g / L and beef extract 12g / L, other conditions are the same as in Example 1. On the scale of anaerobic flask fermentation, the effects of different nitrogen sources on the production of succinic acid by fermentation of plantain syrup were investigated. The results are shown in Table 2.

[0053] Table 2 Effects of different nitrogen sources on banana syrup fermentation

[0054]

[0055] The results showed that the strain produced the highest acid when corn steep liquor was used as the nitrogen source. After 48 hours of fermentation, the yield of succinic acid reached 45.88 g / L. Without adding any nitrogen ...

Embodiment 3- Embodiment 8

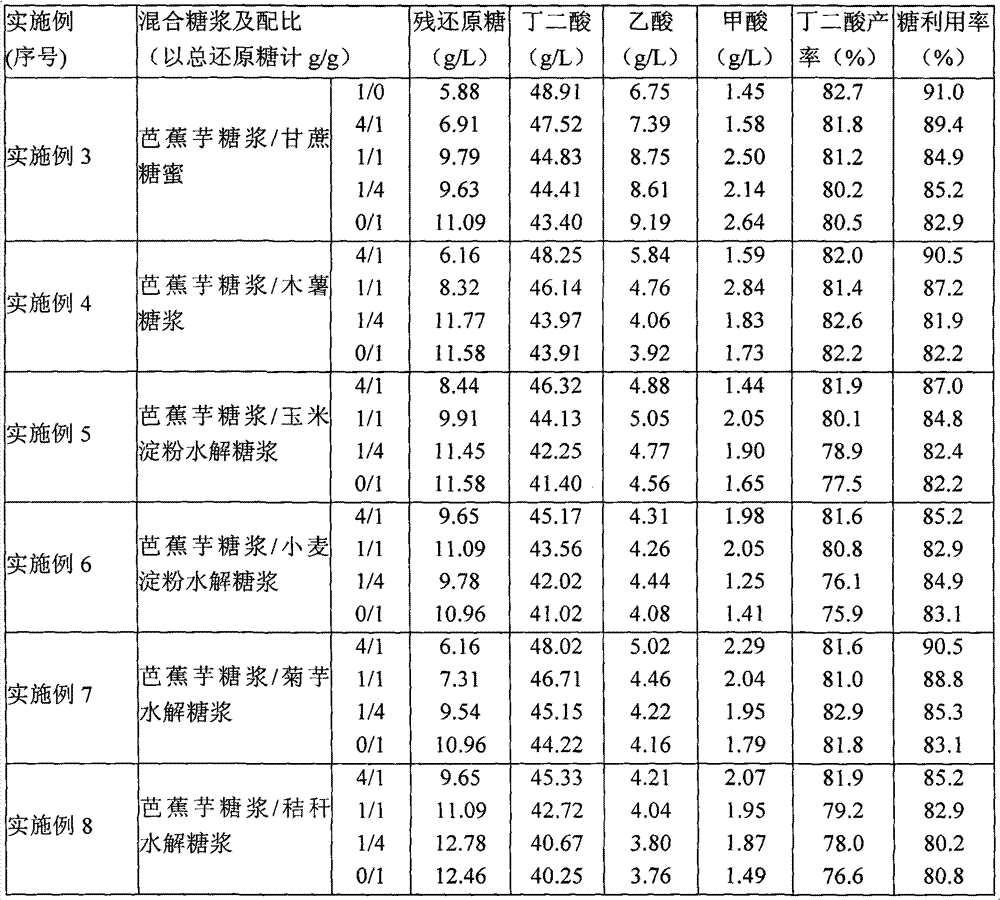

[0057] Take the saccharified plantain taro syrup and mix them with sugar cane molasses, starch raw material hydrolyzed syrup, Jerusalem artichoke hydrolyzed syrup, and straw hydrolyzed syrup in different proportions. The initial total reducing sugar is 65g / L, the fermentation time is 60 hours, and other experimental conditions As in Example 1, see Table 3 for the effect of different ratios of carbohydrate raw materials on fermentation production of succinic acid.

[0058] Table 3 Effect of compound carbohydrate raw materials on fermentation

[0059]

[0060] It can be seen that when the initial reducing sugar concentration is 65g / L, plantain syrup and sugar cane molasses, starch raw material hydrolyzed syrup, Jerusalem artichoke hydrolyzed syrup, straw hydrolyzed syrup and other sugar raw materials in any ratio of mixed syrup can be very good. The fermentation of succinic acid is good, and the level basically reaches 40.25~48.91g / L. The yield of succinic acid to consumed sugar is 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com