Method for preparing composite material of polypyrrole granules and titanium dioxide nanotube array

A technology of polypyrrole particles and titanium dioxide, which is applied in electrolytic organic production, electrolytic components, electrolytic process and other directions, can solve the problems of low utilization rate of solar energy absorption, high semiconductor carrier recombination rate, low quantum efficiency, etc. Photocatalytic performance, simple implementation method, and the effect of large electrochemical response signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

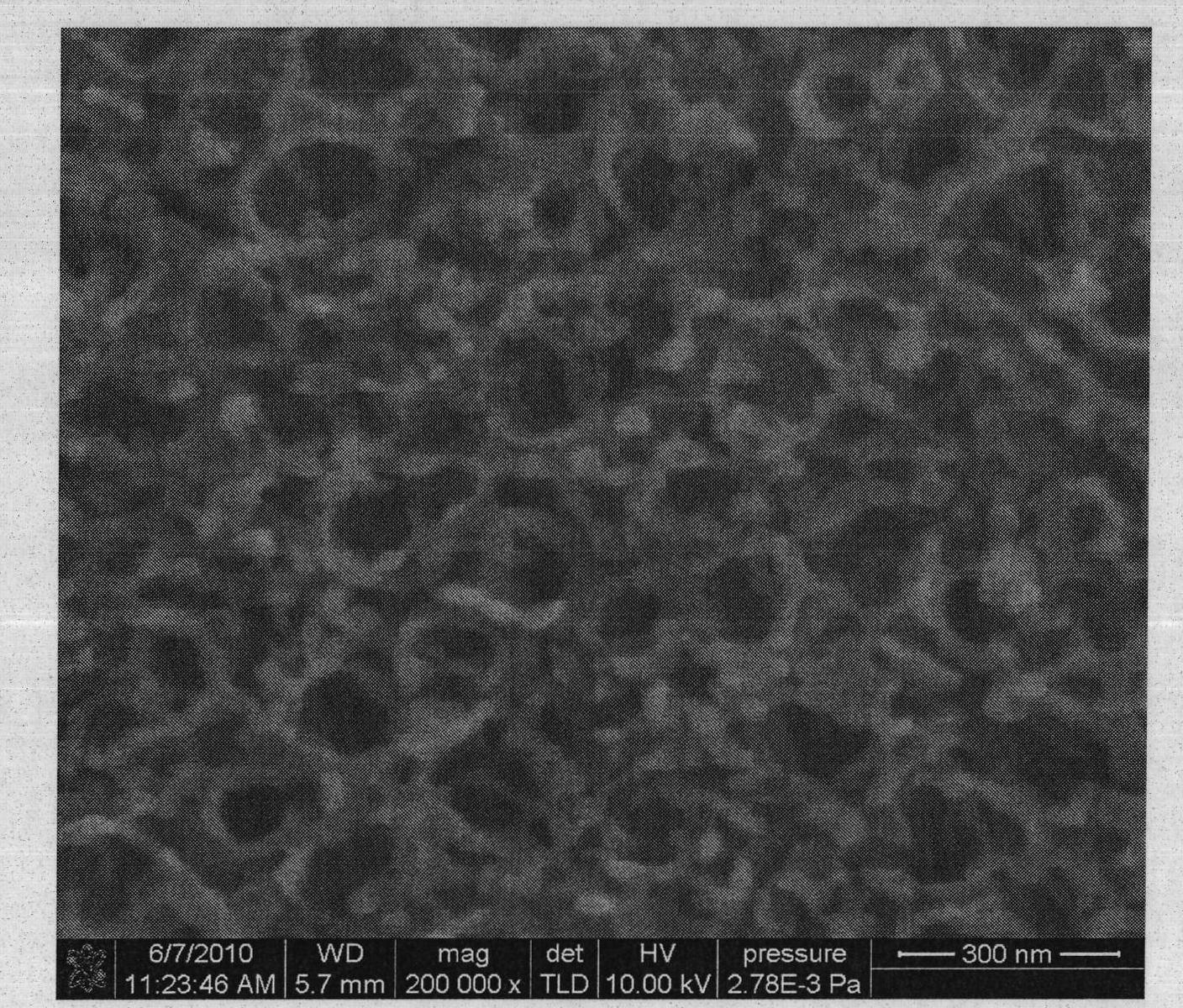

[0032] 1) The titanium dioxide nanotube array is synthesized by anodic oxidation method, and the anatase titanium dioxide nanotube array is obtained by roasting, which specifically includes the following steps:

[0033] (a) Select a titanium foil with a purity greater than or equal to 99.6%, remove the oxides on the surface by grinding with metallographic sandpaper, put it in hydrochloric acid (15-30% by mass), absolute ethanol, and distilled water in sequence, and ultrasonically Wash for 10 minutes to further remove surface oxides;

[0034] (b) Put the cleaned and dried titanium foil as the anode and the platinum as the cathode in 0.17M HF solution, react at room temperature for 1.5h at a voltage of 23V, then take it out and immediately clean it with distilled water to form Amorphous titania nanotube arrays.

[0035] (c) Calcining the amorphous titania nanotube array obtained in step (b) in a nitrogen atmosphere for 1 h at a calcination temperature of 400° C. to obtain an an...

Embodiment 2

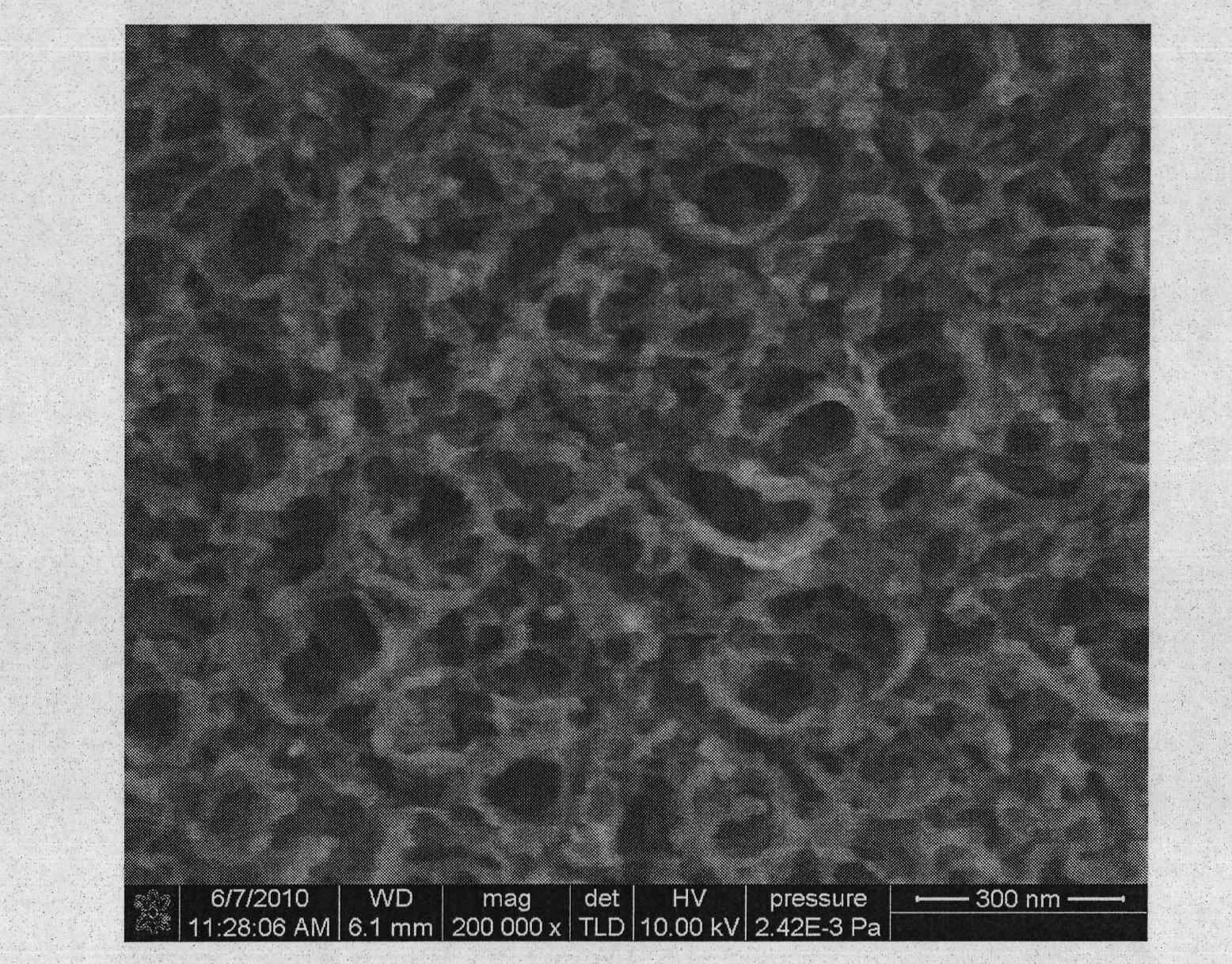

[0038] (a) Select a titanium foil with a purity greater than or equal to 99.6%, remove the oxides on the surface by grinding with metallographic sandpaper, put it in hydrochloric acid (15-30% by mass), absolute ethanol, and distilled water in sequence, and ultrasonically Wash for 12 minutes to further remove surface oxides;

[0039] (b) The cleaned and dried titanium foil is used as an anode, and the platinum sheet is placed in a 0.17M HF solution as a cathode, and reacted at room temperature for 1 hour at a voltage of 25V, and then taken out and immediately cleaned with distilled water. Arrays of crystalline titania nanotubes.

[0040] (c) Calcining the amorphous titania nanotube array obtained in step (b) for 1.2 h in a nitrogen atmosphere at a calcination temperature of 450° C. to obtain an anatase titanium dioxide nanotube array.

[0041] 2) In the aqueous solution composed of sodium dodecylbenzenesulfonate and pyrrole monomer, the calcined titanium dioxide nanotube array...

Embodiment 3

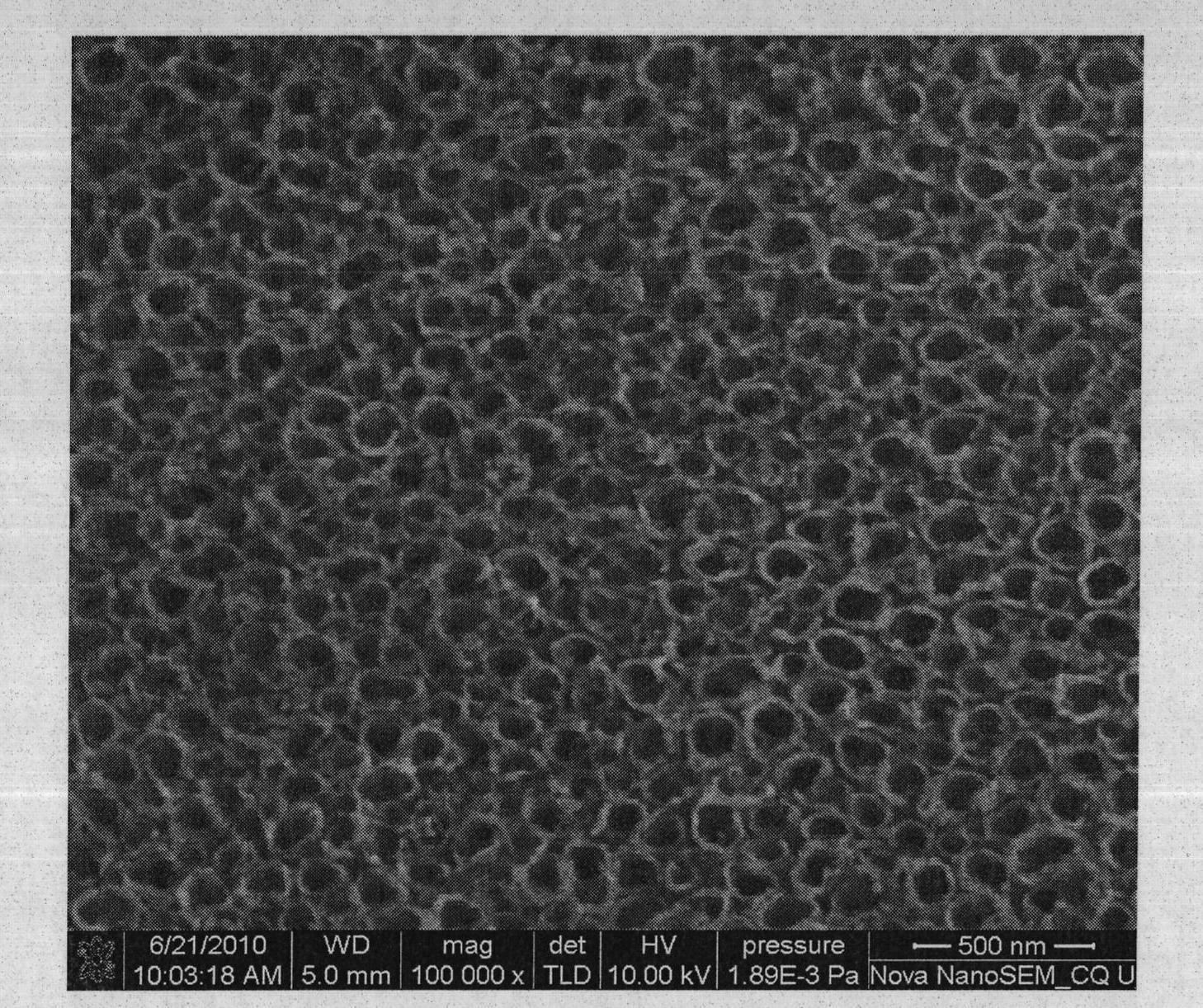

[0043] (a) Select a titanium foil with a purity greater than or equal to 99.6%, remove the oxides on the surface by grinding with metallographic sandpaper, put it in hydrochloric acid (15-30% by mass), absolute ethanol, and distilled water in sequence, and ultrasonically Wash for 15 minutes to further remove surface oxides;

[0044] (b) Put the cleaned and dried titanium foil as the anode, and the platinum sheet as the cathode in 0.17M HF solution, react at room temperature for 1.5h at a voltage of 20V, then take it out and immediately clean it with distilled water, through this step to form Amorphous titania nanotube arrays.

[0045] (c) Calcining the amorphous titania nanotube array obtained in step (b) for 1.5 h in an air atmosphere at a calcination temperature of 450° C. to obtain an anatase titanium dioxide nanotube array.

[0046] 2) In the aqueous solution composed of sodium dodecylbenzenesulfonate and pyrrole monomer, the calcined titanium dioxide nanotube array is us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com