Method for preparing hierarchical porous titanium silicalite TS-1

A technology of titanium silicalite, TS-1, applied in the field of preparation of multi-level porous titanium silicalite TS-1, to achieve the effect of reducing synthesis cost, simplifying the preparation process, and eliminating cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

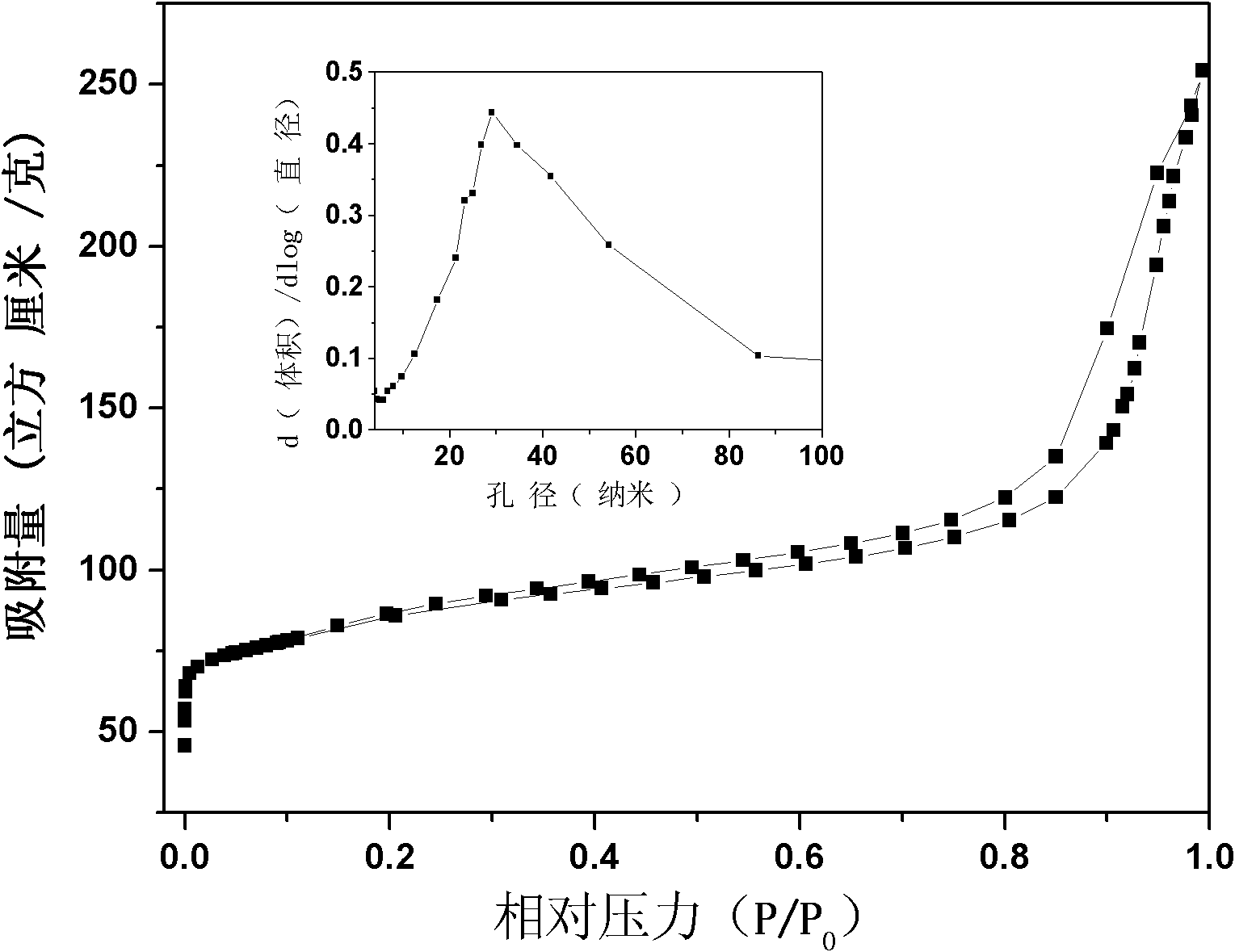

Embodiment 1

[0024] Get 1.5g of tetrapropylammonium bromide, 8ml of deionized water and 3.9ml (weight 30%) of silica sol, and add successively in 8.4g (weight 50%) of caramel solution; take 0.16ml of tetrabutyl titanate solution In 1.6ml of isopropanol (volume ratio is 1:10), mix well and slowly drop into the above solution, the molar ratio composition of tetrapropylammonium bromide, deionized water, silica sol and tetrabutyl titanate 0.24:36.5:1:0.02, caramel and silica sol (SiO 2 The mass ratio of 3:1; the resulting mixture was heated to 80° C. and stirred for 2 h; then the mixture was placed at 170° C. for 28 h to obtain a black solid dry glue. Grind the dry glue into powder and put it in the container in the middle of the crystallization kettle, add 9ml of ethylenediamine and 12ml of water at the bottom; put the crystallization kettle at 170°C for 7d. After washing, filtering and drying the obtained solid, it was calcined at 650° C. for 10 h to obtain the multi-level channel TS-1. In...

Embodiment 2

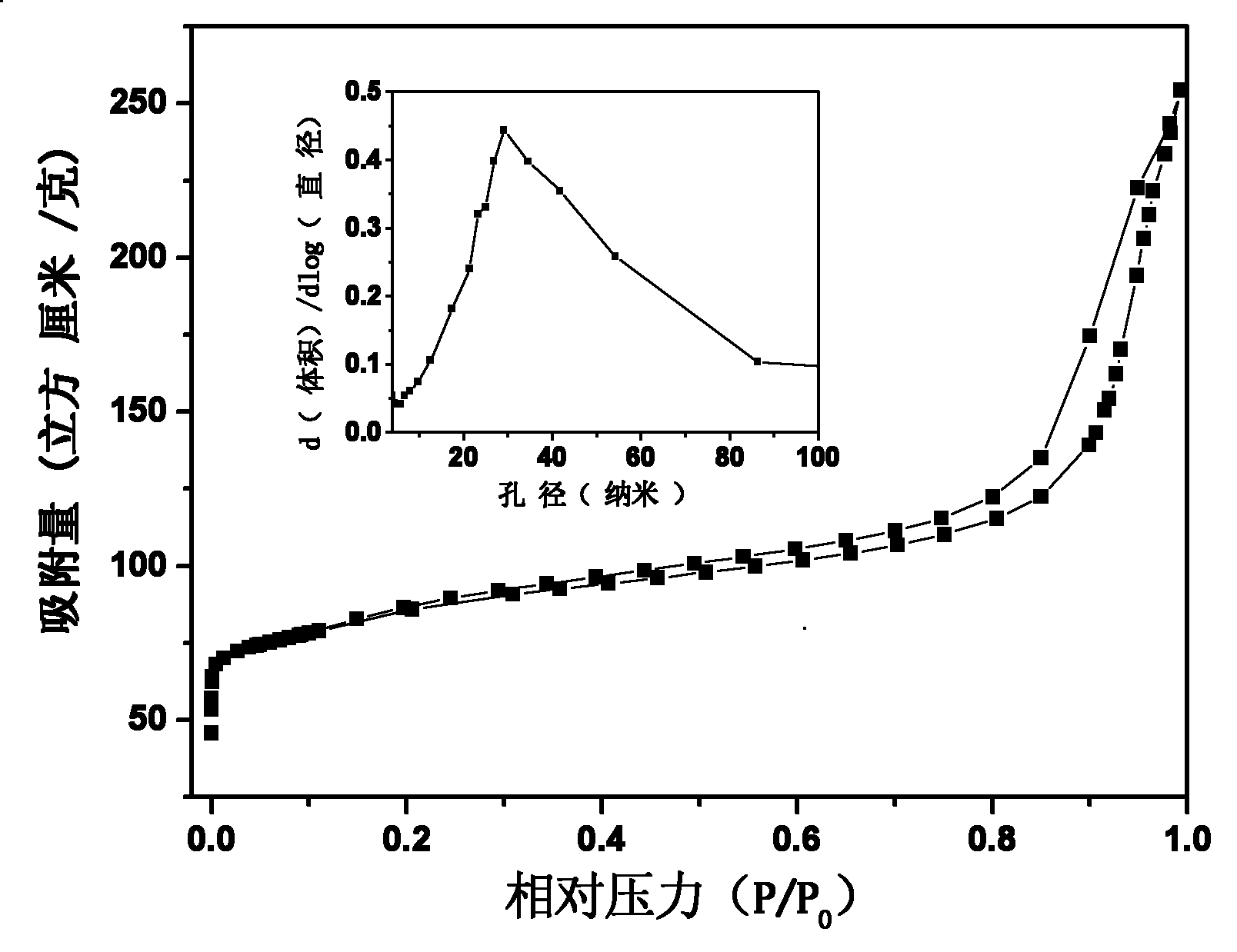

[0026] Get 1.5g of tetrapropylammonium bromide, 8ml of deionized water and 3.9ml (30% by weight) of silica sol, and add successively in 2.8g (50% by weight) of caramel solution; In 1.6ml of isopropanol (volume ratio is 1:10), mix well and slowly drop into the above solution, the molar ratio composition of tetrapropylammonium bromide, deionized water, silica sol and tetrabutyl titanate 0.24:30:1:0.02, caramel and silica sol (based on SiO 2 The mass ratio of 1:1; the resulting mixture was heated to 80° C. and stirred for 2 h; then the mixture was placed at 170° C. for 24 h to obtain a black solid dry glue. Grind the dry glue into powder and put it in the container in the middle of the crystallization kettle, add 9ml of ethylenediamine and 12ml of water at the bottom; put the crystallization kettle at 170°C for 7d. After washing, filtering and drying the obtained solid, it was calcined at 650° C. for 10 h to obtain the multi-level channel TS-1.

Embodiment 3

[0028] Get 1.5g of tetrapropylammonium bromide, 8ml of deionized water and 3.9ml (30% by weight) of silica sol, and add successively in 5.6g (50% by weight) of caramel solution; In 1.6ml of isopropanol (volume ratio is 1:10), mix well and slowly drop into the above solution, the molar ratio composition of tetrapropylammonium bromide, deionized water, silica sol and tetrabutyl titanate 0.24:33.3:1:0.02, caramel and silica sol (SiO 2 The mass ratio of 2:1; the resulting mixture was heated to 80° C. and stirred for 2 h; then the mixture was placed at 170° C. for 36 h to obtain a black solid dry glue. Grind the dry glue into powder and put it in the container in the middle of the crystallization kettle, add 9ml of ethylenediamine and 12ml of water at the bottom; put the crystallization kettle at 170°C for 7d. After washing, filtering and drying the obtained solid, it was calcined at 650° C. for 10 h to obtain the multi-level channel TS-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com