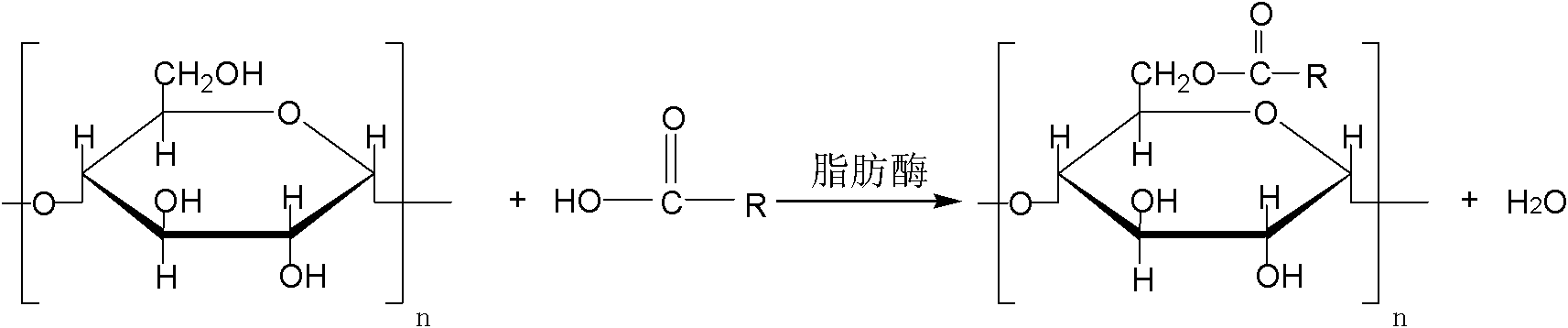

Method for preparing starch aliphatic ester by enzyme catalysis

A starch fatty acid ester, catalytic preparation technology, applied in the direction of fermentation, etc., can solve the problems of unsuitable products and high requirements for reaction conditions, and achieve the effect of simple production equipment, wide source of raw materials, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

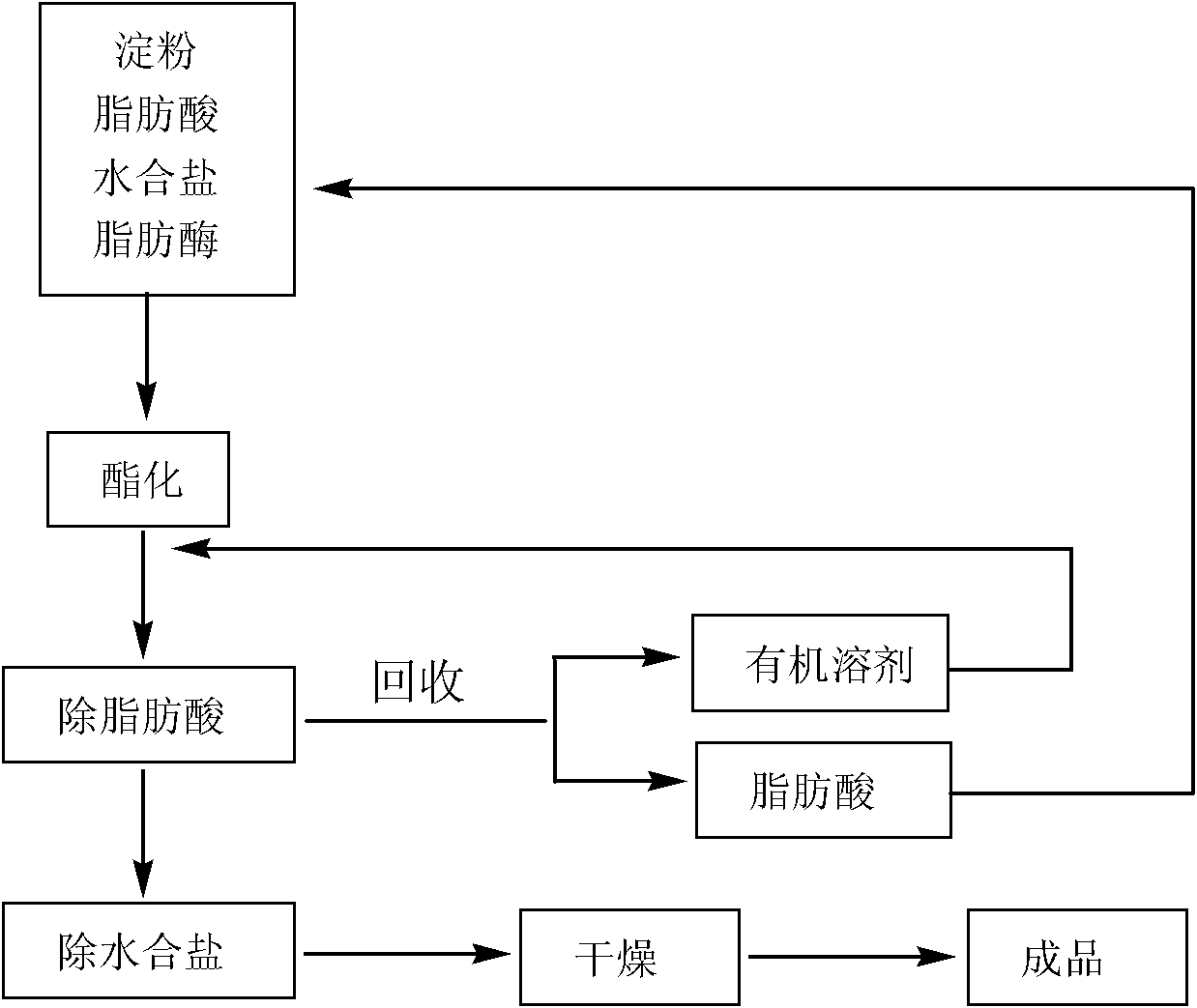

[0048] A method for preparing starch fatty acid ester by enzyme catalysis, the steps are as follows:

[0049] (1) Mix 20 weight units of stearic acid with 6 weight units of starch, add 1 weight unit of sodium pyrophosphate and 0.6 weight units of lipase after the solution is melted, and then react at a constant temperature. Time: 42h, the starch fatty acid ester crude product was obtained;

[0050] The lipase LipozymeTL IM was purchased from Novozymes and activated with 2.5% sodium chloride solution.

[0051] (2) adding organic solvent n-hexane to the above-mentioned powdered fatty acid ester crude product, then leaching and centrifuging, separating excessive stearic acid, and simultaneously organic solvent and stearic acid are reclaimed;

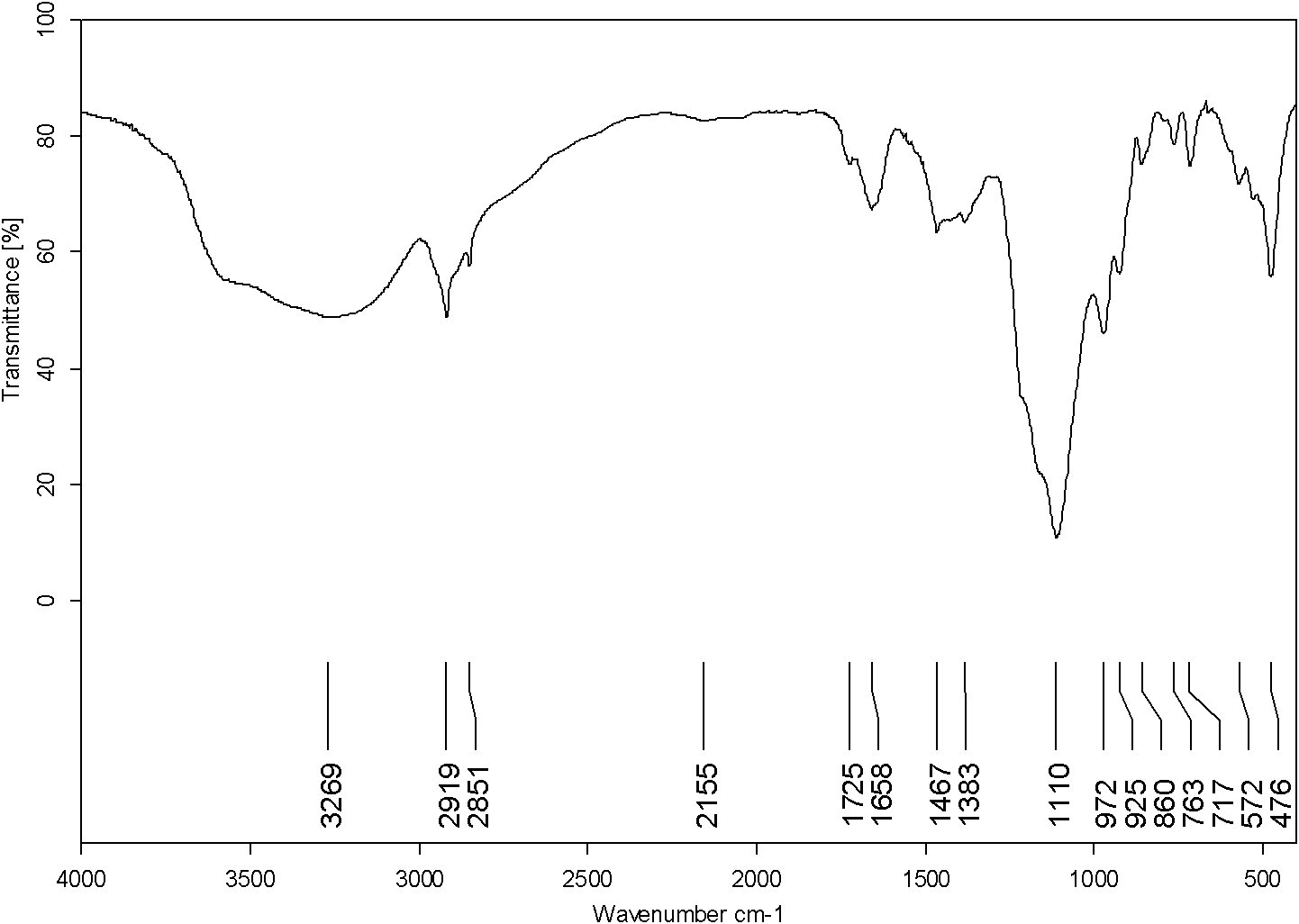

[0052] (3) add distilled water in the crude product after extraction, to dissolve the sodium pyrophosphate in the crude product, wash in three times, suction filter after washing, dry at 40 DEG C, obtain starch stearate after drying, by me...

Embodiment 2

[0054] A method for preparing starch fatty acid ester by enzyme catalysis, the steps are as follows:

[0055] (1) Mix 20 weight units of palmitic acid with 6 weight units of starch, add 1 weight unit of sodium pyrophosphate and 0.6 weight units of lipase after the solution is melted, and then react at a constant temperature, constant temperature conditions: 65 ° C, reaction time : 42h, obtain starch fatty acid ester crude product;

[0056] The lipase LipozymeTL IM was purchased from Novozymes and activated with 2.5% sodium chloride solution.

[0057] (2) add organic solvent normal hexane in above-mentioned powdery fatty acid ester crude product, then lixiviate and centrifuge, separate excessive palmitic acid, organic solvent and palmitic acid are reclaimed simultaneously;

[0058] (3) Add distilled water to the crude product after extraction to dissolve the sodium pyrophosphate in the crude product, wash in three times, filter with suction after washing, dry at 40°C, and obta...

Embodiment 3

[0060] A method for preparing starch fatty acid ester by enzyme catalysis, the steps are as follows:

[0061] (1) Mix 20 weight units of myristic acid with 6 weight units of starch, add 1 weight unit of sodium pyrophosphate and 0.6 weight units of lipase after the solution is melted, and then react at a constant temperature. The constant temperature conditions are: 65°C, Reaction time: 42h, the starch fatty acid ester crude product was obtained;

[0062] The lipase LipozymeTL IM was purchased from Novozymes and activated with 2.5% sodium chloride solution.

[0063] (2) adding the organic solvent n-hexane to the above-mentioned fatty acid ester crude product, then extracting and centrifuging to separate excess myristic acid, and reclaim the organic solvent and myristic acid simultaneously;

[0064] (3) Add distilled water to the crude product after extraction to dissolve the hydrated salt sodium pyrophosphate in the crude product, wash in three times, suction filter after wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com