Fluazinam dry suspending agent and preparation method thereof

A technology of fluazinam dry and suspending agent, which is applied in the field of pesticides and fungicides, can solve problems such as unsatisfactory plant disease control effects, and achieve the effects of continuous production, good dispersibility, and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

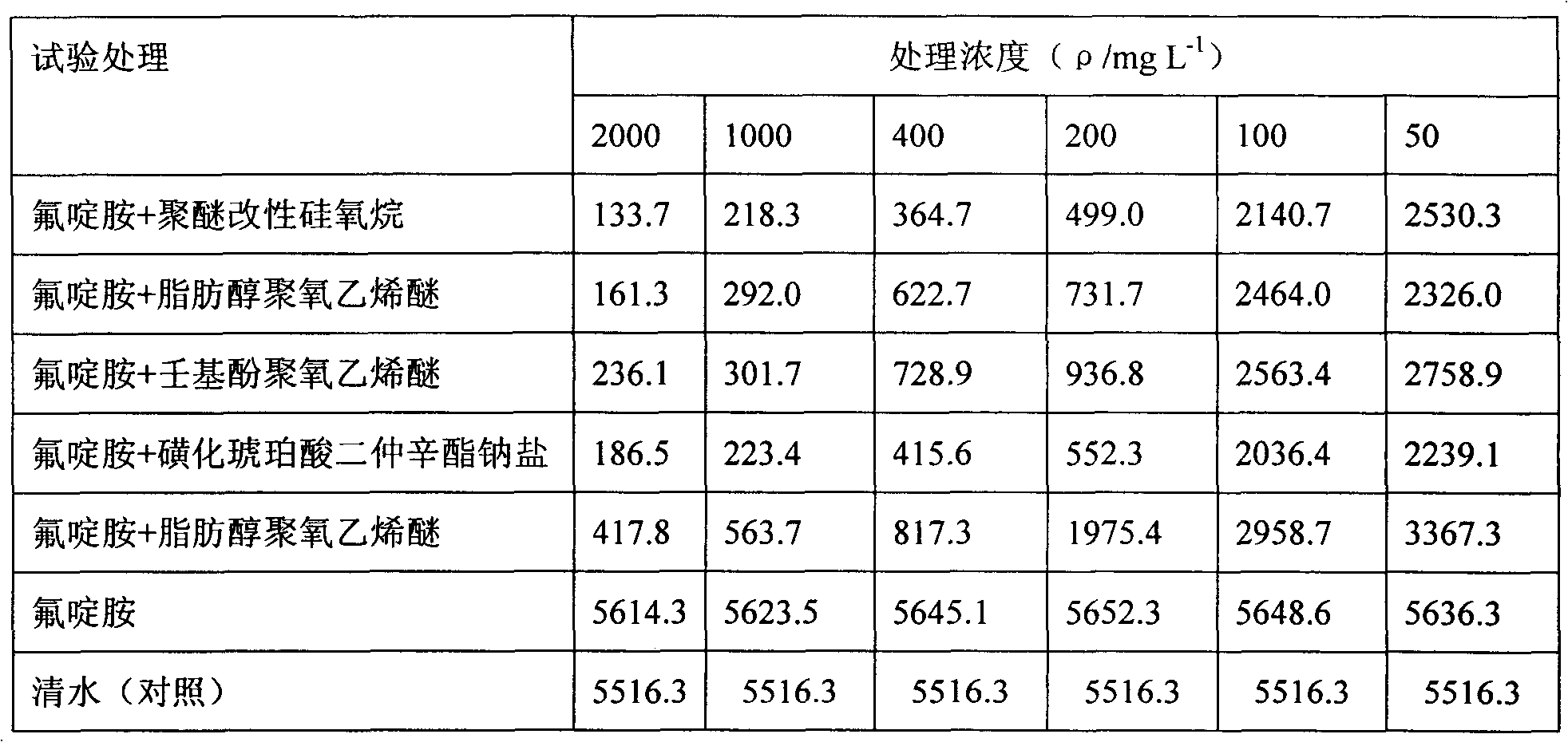

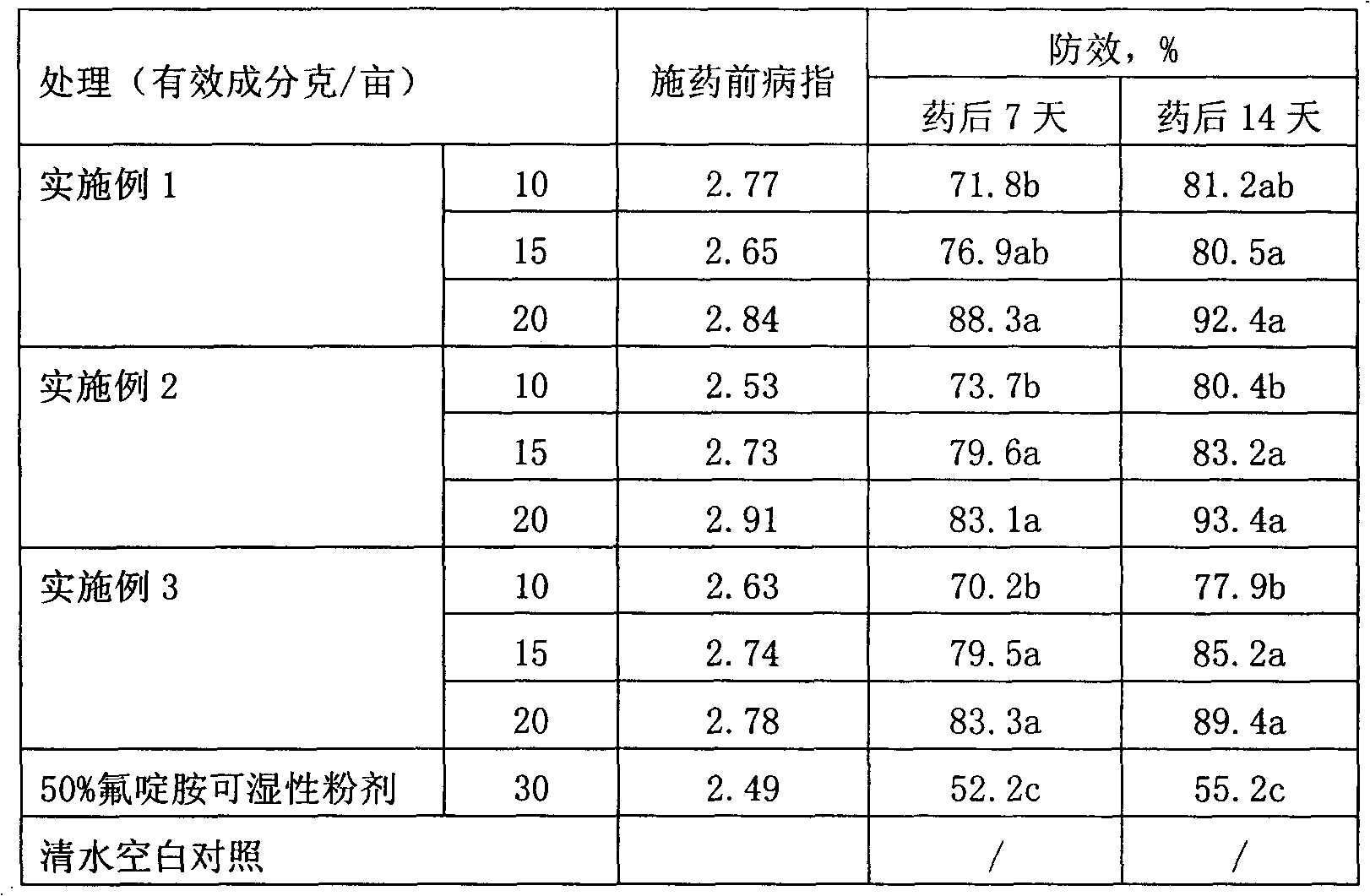

Method used

Image

Examples

Embodiment 1

[0042] Take the original drug of fluazinam containing 10.5g of active ingredients, 3.0g of sodium alkylphenol polyoxyethylene ether sulfate, 12.0g of calcium lignosulfonate, 1.5g of polyethylene glycol, 0.5g of organic silicone, and 6.0g of carboxycellulose g, 0.5g of fatty alcohol polyoxyethylene ether, 100g of diatomaceous earth, after mixing and stirring evenly, add 200g of water, wet grinding to make a suspension, and then spray, dry and sieve to obtain 10% fluridine Amine dry suspending agent. After testing, the active ingredient content is 10.2%, moisture ≤ 1.0%, pH 7.8, fineness (through 45um) ≥ 98%, suspension rate ≥ 90%, persistent foaming (1min) ≤ 10ml, wetting time ≤ 40s, Basically no dust, accelerated storage stability is qualified.

Embodiment 2

[0044] Take the original drug of fluazinam containing 31.0g of active ingredients, 4.0g of sodium methylene bis-naphthalene sulfonate, 8.0g of pull-open powder, 1.5g of polyethylene glycol, 0.5g of organic silicone, 10.0g of white carbon black, fat Alcohol polyoxyethylene ether 1.0g, diatomaceous earth make up 100g, mix and stir evenly, add water 300g, wet grinding to make suspending agent, and then spray, dry and sieve to get 30% fluazinam dry suspension agent. After testing, the active ingredient content is 30.5%, moisture ≤ 1.0%, pH 8.0, fineness (through 45um) ≥ 98%, suspension rate ≥ 90%, persistent foaming (1min) ≤ 10ml, wetting time ≤ 40s, Basically no dust, accelerated storage stability is qualified.

Embodiment 3

[0046] Take fluazinam original drug containing 31.0g active ingredient, castor oil polyoxyethylene ether 4.0g, lignosulfonate 6.0g, polyethylene glycol 1.5g, organosilicone 0.5g, white carbon black 5.0g, sulfuric acid Ammonium 18.0g, polyether modified siloxane 0.8g, kaolin to make up 100g, after mixing and stirring evenly, add 300g of water, wet grinding to make a suspension, and then spray, dry, and sieve to obtain 30% fluoride Pyridine amine dry suspension concentrate. After testing, the active ingredient content is 30.4%, moisture ≤ 1.0%, pH 7.9, fineness (through 45um) ≥ 98%, suspension rate ≥ 90%, persistent foaming (1min) ≤ 10ml, wetting time ≤ 40s, Basically no dust, accelerated storage stability is qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com