Electric spark induced controlled combustion and discharge machining corrosion removing method

A technology of electric discharge machining and electric spark, which is applied in the field of electric spark induced controllable combustion and electric discharge machining erosion, can solve the problems of low efficiency of electric discharge machining, achieve the effect of improving material erosion rate, increasing energy, and reducing electrode loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

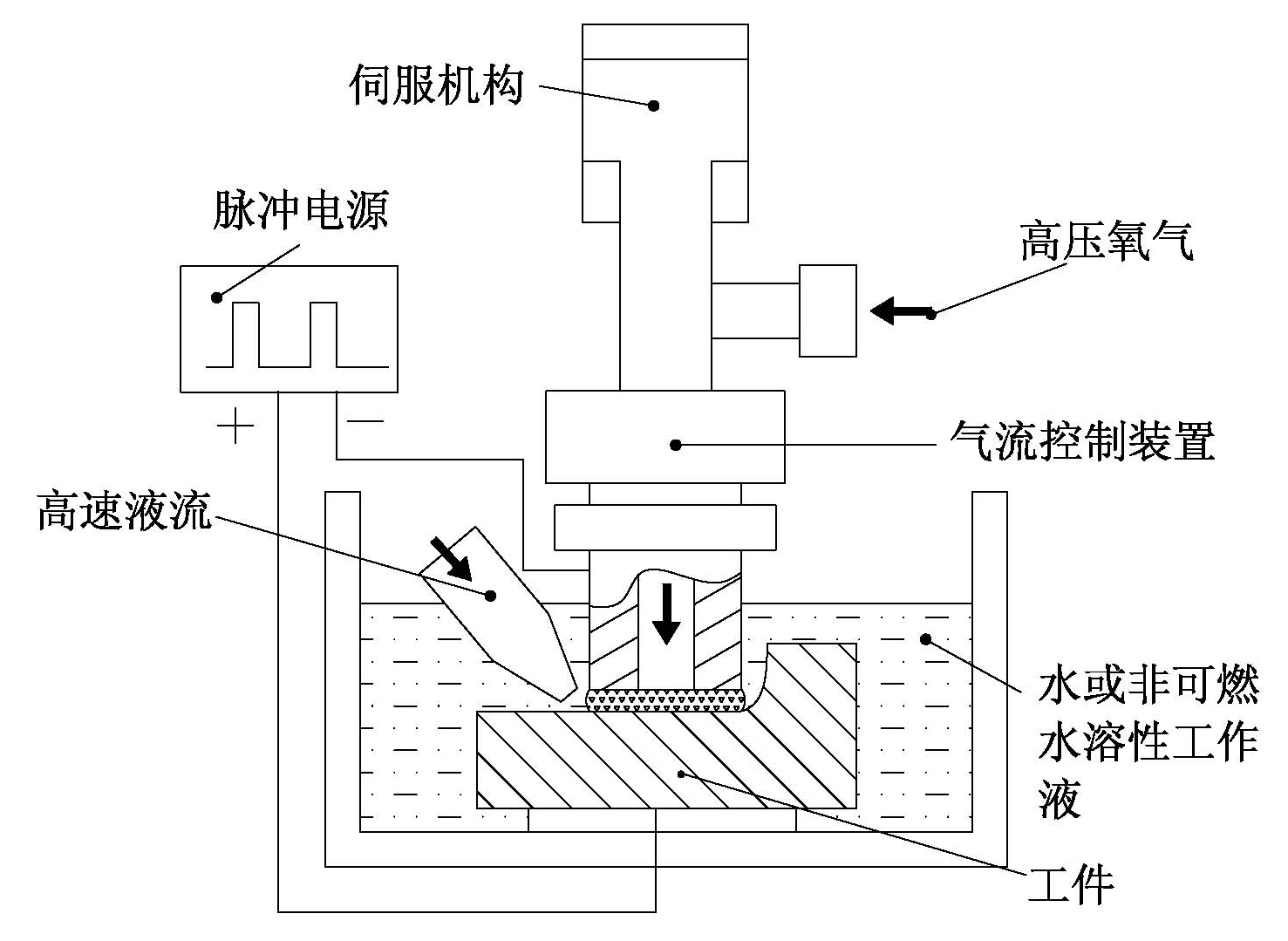

[0039] Such as figure 1 , 2 shown.

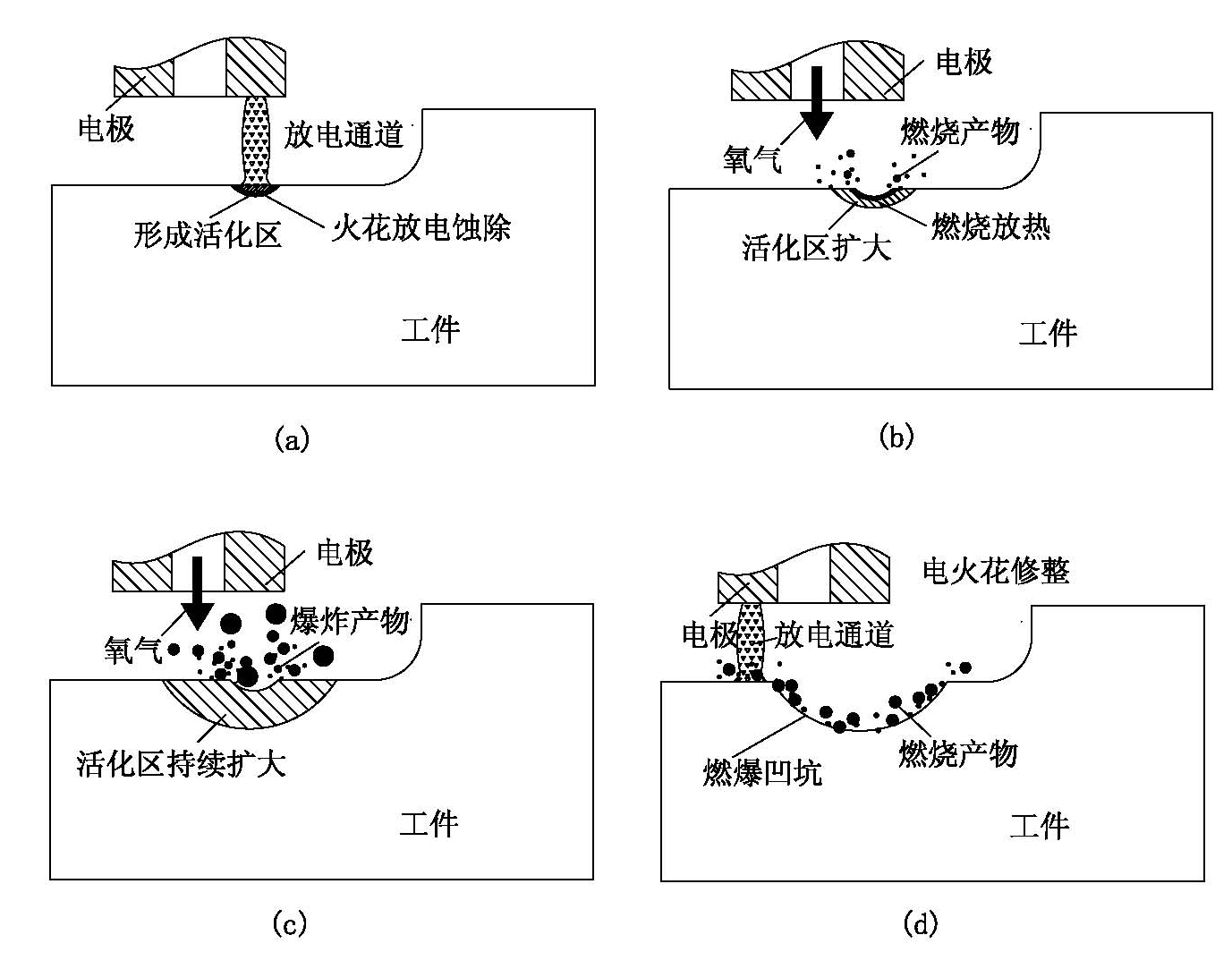

[0040] A kind of die steel Cr12 electric spark induces controllable combustion and electric discharge machining etch method, it comprises the following steps:

[0041] The first step is to build a processing system. Such as figure 1 As shown, the tubular electrode is connected to the airflow control device, the electrode can be rotated, and the high-pressure oxygen is transformed into intermittent adjustable intermittent oxygen flow under the action of the airflow control device. The electrode and Cr12 are respectively connected to the two poles of the pulse power supply to generate electric spark discharge. Water is used as the working medium. The liquid surface is more than 20mm away from the processing area to form a certain water pressure to strengthen the combustion effect. The water flow is used (the pressure depends on the gas pressure) ) to flush the processing area to speed up the discharge of erosion products.

[0042] The se...

example 2

[0052] An electric spark induced controllable combustion and electric discharge machining erosion method of superalloy GH4169, which differs from Example 1 in that the base material is different. The rest are the same as Example 1.

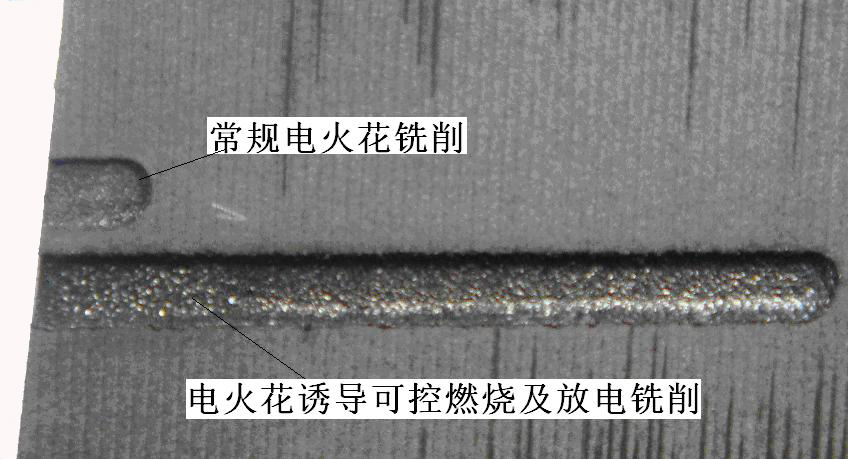

[0053] For an application example of high-temperature alloy GH4169 using EDM-induced controllable combustion milling and conventional EDM, as shown in Table 2, the physical photos of the processed workpiece corresponding to the same processing time are as follows image 3 shown.

[0054] Table 2 Comparison of GH4169 EDM-induced controllable combustion and EDM with conventional EDM methods

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com