Preparation method of dysprosium coordinated compound emitting pale yellow light

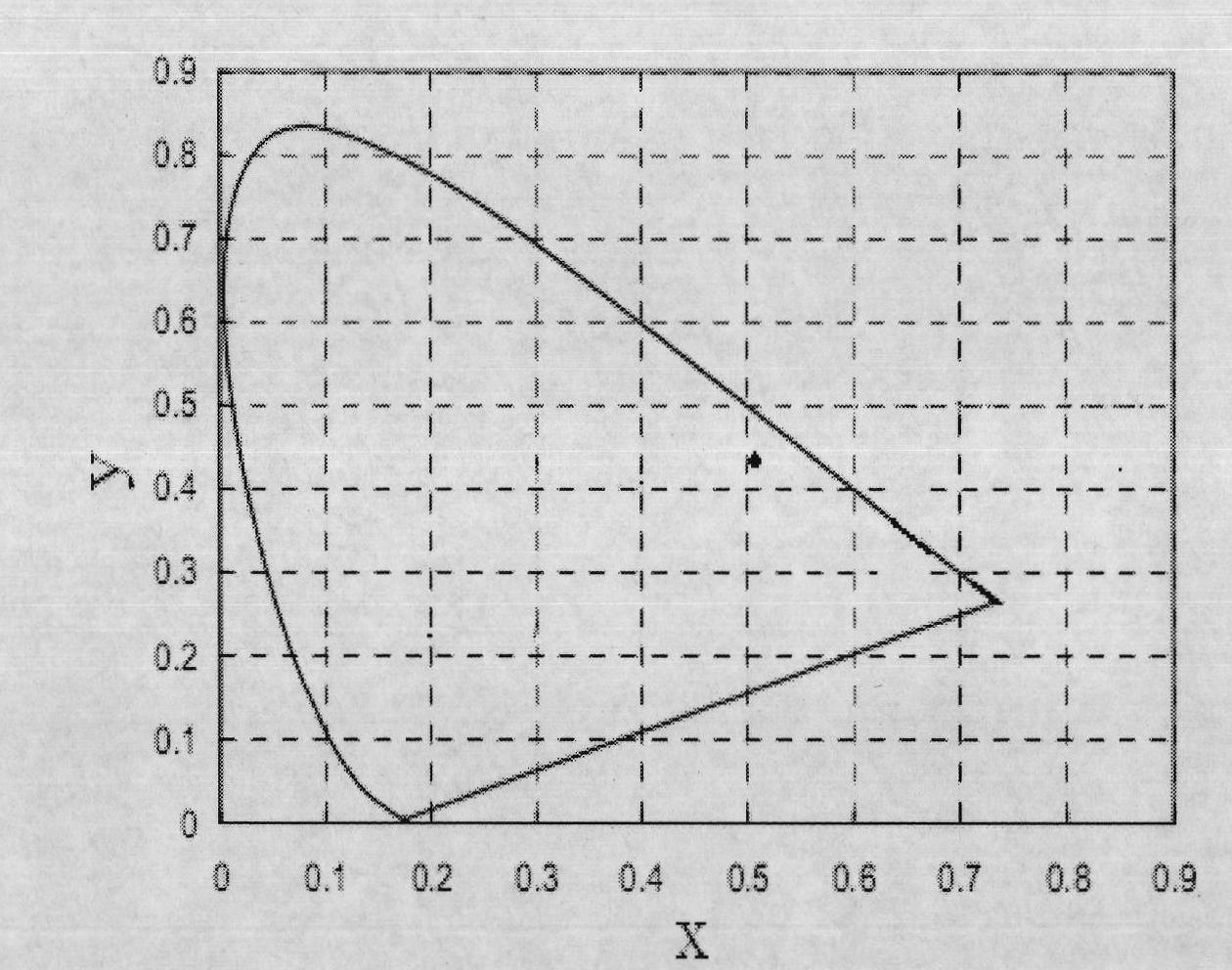

A complex and yellow light technology, which is applied in the direction of luminescent materials, compounds containing elements of group 3/13 of the periodic table, chemical instruments and methods, etc., can solve the problem of high color line, difficult to observe light and fluorescence emission Problems such as narrow band half-width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

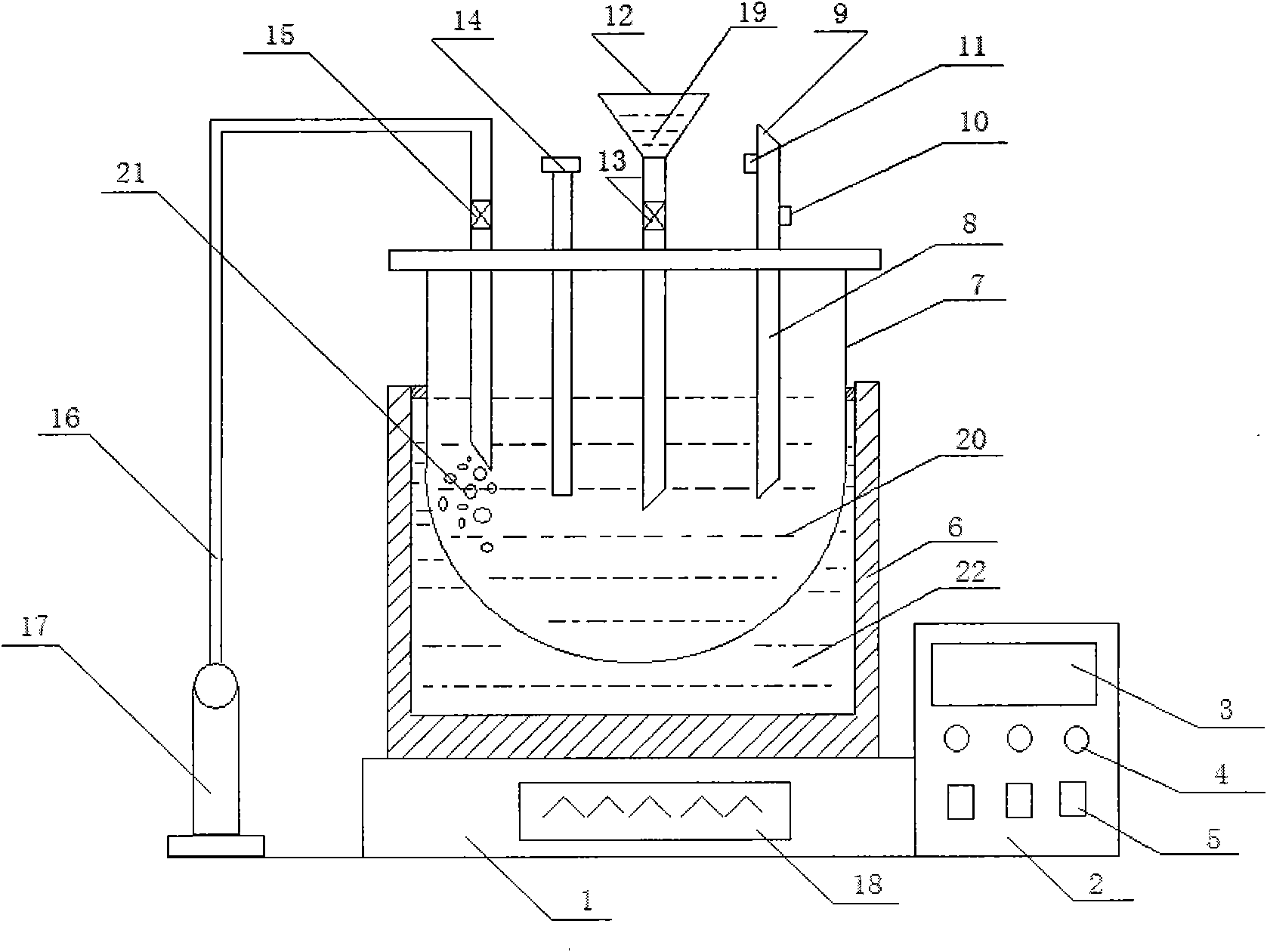

Method used

Image

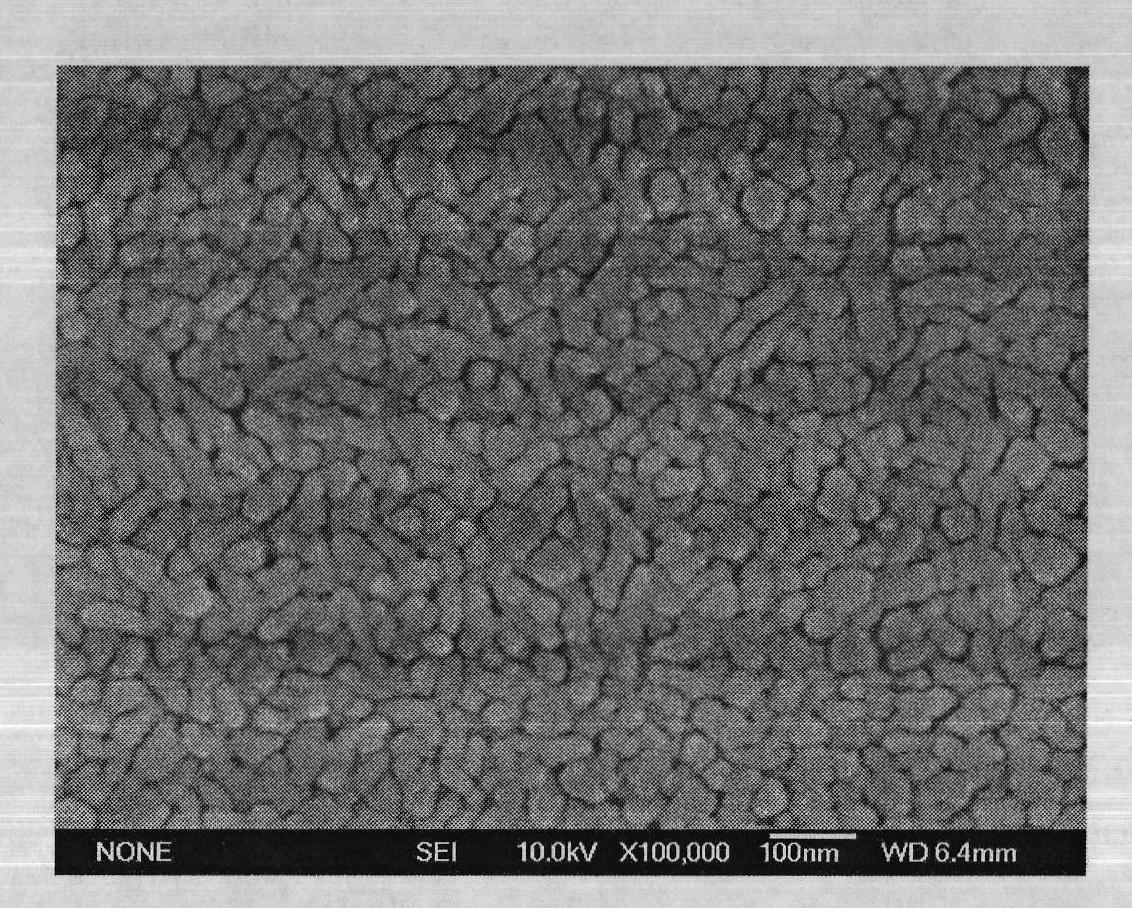

Examples

Embodiment 1

[0115] Weigh 6.78g±0.0002g of benzoylbenzoic acid and 2.78g±0.0002g of triphenylphosphine oxide, add 100mL±2mL of absolute ethanol, dissolve, stir, heat to 50°C±2°C, and adjust the pH value to 6.0±2°C 0.2, carry out water cycle condensation; drop in dysprosium chloride ethanol solution, drop in speed 1mL / min, drop in time 30min±2min, drop in, stir while heating, then add dropwise sodium hydroxide aqueous solution, adjust the pH value 6.0±0.2, continue to react for 180min±2min, after the reaction is completed, cool naturally to room temperature 25°C.

Embodiment 2

[0117] Weigh 6.78g±0.0002g of benzoylbenzoic acid and 1.8g±0.0002g of 1,10-phenanthroline, add 100mL±2mL of ethanol, dissolve, stir, heat to 50°C±2°C, and adjust the pH value to 6.0 ±0.2, carry out water cycle condensation; drop in dysprosium chloride ethanol solution, drop in speed 1mL / min, drop in time 30min±2min, drop in, stir while heating, then add dropwise sodium hydroxide aqueous solution to adjust the pH value 6.0±0.2, continue to react for 180min±2min, after the reaction is completed, cool naturally to room temperature 25°C.

Embodiment 3

[0119]Weigh 3.3g±0.0002g of acetylacetone and 1.55g±0.0002g of 2,2’-bipyridine, add 100mL±2mL of absolute ethanol, dissolve, stir, heat to 50°C±2°C, and adjust the pH value to 6.0±0.2 , carry out water cycle condensation; drop in dysprosium chloride ethanol solution, drop in speed 1mL / min, drop in time 30min±2min, drop in, stir while heating, then add dropwise sodium hydroxide aqueous solution, adjust the pH value to 6.0 ±0.2, continue to react for 180min±2min, after the reaction is completed, cool naturally to 25°C.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap