Amphiphilic polymer pigment wetting dispersant for water-based coating and preparation method thereof

An amphiphilic polymer and wetting and dispersing agent technology, which is used in the chemical coatings manufacturing industry and the field of pigment wetting and dispersing agents for water-based coatings, can solve the problems of high monomer purity requirements, limited application scope and harsh reaction conditions. Achieve low cost, improved performance, low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

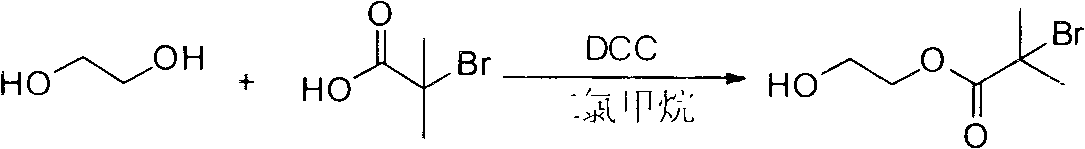

[0037] (1) The preparation method of initiator is as follows:

[0038] In a 500mL round bottom flask, add 18.6g (0.3mol) ethylene glycol, 41.28g (0.2mol) N, N'-dicyclohexylcarbodiamide (DCC), 33.4g (0.2mol) 2-bromo isobutyric acid and 200 mL of dichloromethane. The solution was stirred, and 248 mg (2 mmol) of 4-dimethylaminopyridine was added in an ice-water bath, and reacted overnight at room temperature. The resulting reaction mixture was filtered to remove the precipitate and washed with 25 mL of dichloromethane. The solvent obtained was removed by a rotary evaporator, and the residue was crude hydroxyethyl dibromoisobutyrate. Purified by column chromatography, the eluent was petroleum ether / diethyl ether (4 / 1 to 2 / 3 v / v) mixture.1 H NMR (CDCl 3 ,): δ1.92(s, 6H), 2.39(s, 1H), 3.82(t, 2H), 4.28(t, 2H).

[0039] The reaction equation is:

[0040]

[0041] (2) The preparation method of TPMA is as follows:

[0042] In 75mL of dichloromethane, add 0.54g (5.26mmol) of 2-...

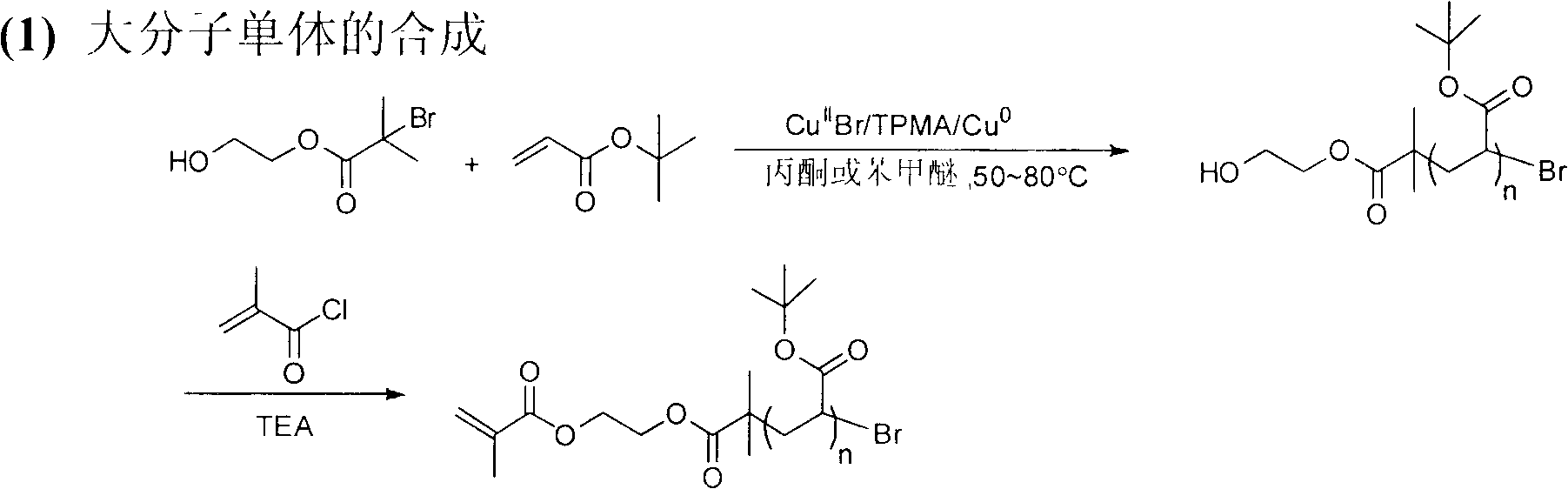

Embodiment 1

[0045] Put 3.5g ring-shaped copper wire and magnetic stirring bar into a 100mL Schlenk bottle, blow nitrogen, and vacuum three times (deoxygenation); 9.0g (70.2mmol) tert-butyl acrylate, CuBr 2 (3.63mg, 1.62×10 -2 mmol) and TPMA complex (57.8mg, 19.89×10 -2 mmol) was dissolved in 9mL anisole, deoxidized with high-purity nitrogen for 30min, then sealed with a syringe and transferred to a Schlenk bottle, and after magnetic stirring for 15min, added the initiator bromoisobutyrate hydroxyethyl ( 520mg, 198.9×10 -2 mmol) in anisole solution (1 mL), in an oil bath at 80° C. under a nitrogen atmosphere, and reacted for 9 h. The resulting solution was precipitated in methanol and water mixture (volume ratio 1:3) and dried to obtain a pale yellow solid macromolecular precursor with number average molecular weight = 1000-5500, molecular weight distribution PDI = 1.26, and a conversion rate of 91%.

[0046] 5 g of the macromolecular precursor of the product prepared above and triethyl...

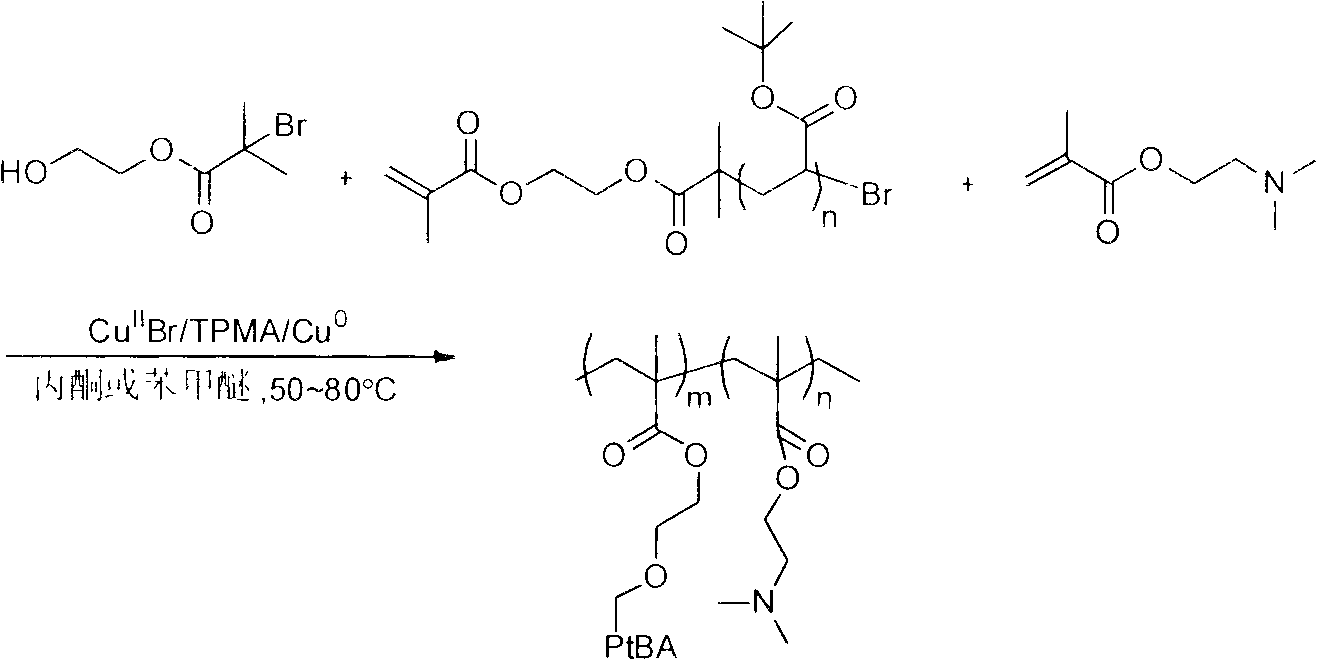

Embodiment 2

[0061] Put 2g ring-shaped copper wire and magnetic stirring bar into a 100mL Schlenk bottle, add 8.1g (27mmol) polyethylene glycol monomethyl ether methacrylate macromer (MPEG-300) (Mn=300), CuBr 2 (0.4mg, 17.8×10 -4 mmol), TPMA (4.36mg, 1.5×10 -2 mmol), dimethylaminoethyl methacrylate (DMAEMA) (4.24g, 27mmol), initiator bromoisobutyrate hydroxyethyl (31.6mg, 15 × 10 -2 mmol) and 7 mL of acetone, freezing in liquid nitrogen-vacuumizing-inflating nitrogen and melting at room temperature, repeated deoxygenation 3 times. Stir the oil bath at 30°C for 13h. The solution obtained from the reaction was precipitated in n-hexane and then dried to obtain a light yellow wetting and dispersing agent (solid), number average molecular weight = 11000-95000, molecular weight distribution PDI = 1.23, conversion rate 89%.

[0062] The wetting and dispersing experiment of this dispersant:

[0063] Dispersion of Phthalocyanine Blue (Copper)

[0064] Copper phthalocyanine: 3 grams

[0065] D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com