Sialon-graphite composite silicon carbide material and preparation method thereof

A technology of compounding silicon carbide and silicon carbide is applied in the field of blast furnace lining refractory materials, which can solve the problems of high requirements for equipment sealing and pressure resistance, relatively high requirements for high temperature resistance, and is not suitable for large-scale production, and achieves easy mass production. , Low production cost, reducing the effect of furnace body joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

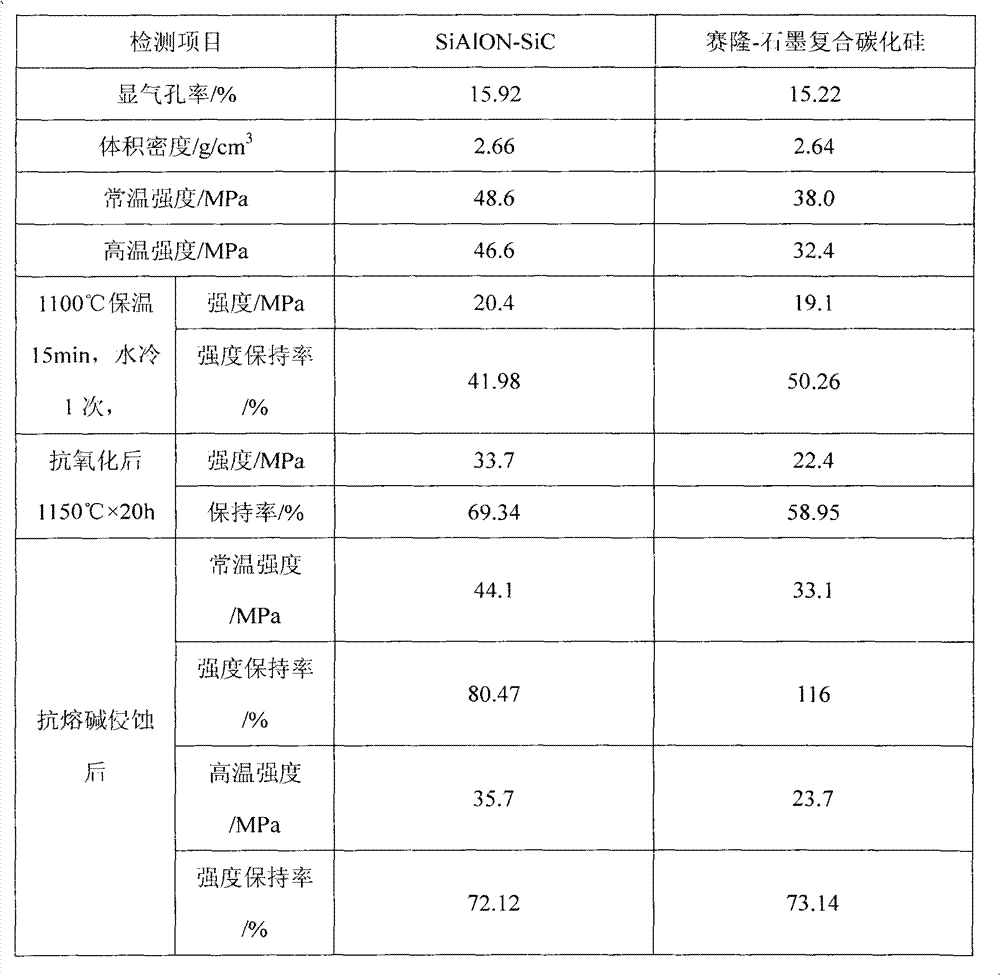

Examples

Embodiment 1

[0022] According to the ratio of mass content 6%, 3%, 6%, 10%, 10%, 45%, 20%, silicon powder, aluminum powder, alumina powder, flake graphite (45 μm) and silicon carbide coarse (1.43~ 2.5mm), medium (0.5-1.43mm), and fine particles (0.1-0.5mm) are weighed for later use. Among them, silicon powder, aluminum powder, and alumina powder are co-ground for 30 minutes to prepare mixed fine powder for later use.

[0023] Mix coarse, medium and fine silicon carbide particles in a kneader for 3 minutes, then add 5% binder phenolic resin and 0.5% solvent absolute ethanol and mix for 2 minutes to make the binder form on the surface of silicon carbide particles To form a uniform film, add graphite and knead for 5 minutes to ensure that the graphite is evenly coated on the surface of the silicon carbide particles, and finally add the pre-prepared mixed fine powder and knead for 10 minutes to prepare a billet. Press the billet into 25×25×125mm with a pressure of 120MPa on a hydraulic press ...

Embodiment 2

[0025] According to the ratio of mass content 8%, 2%, 8%, 8%, 12%, 42%, 20%, silicon powder, aluminum powder, alumina powder, flake graphite (325 μm) and silicon carbide coarse (1.43~ 2.5mm), medium (0.5-1.43mm), and fine particles (0.1-0.5mm) are weighed for later use. Among them, silicon powder, aluminum powder and alumina powder are co-ground for 20 to 30 minutes to prepare mixed fine powder for later use.

[0026] Mix the coarse, medium and fine particles of silicon carbide in a kneader for 3 minutes, then add 4.5% of the total amount of raw materials as a binder phenolic resin and 0.5% solvent ethylene glycol and mix for 2 minutes to make the binder on the surface of the silicon carbide particles Form a uniform film, then add graphite and knead for 6 minutes to ensure that the graphite is evenly coated on the surface of the silicon carbide particles, and finally add the pre-prepared mixed fine powder and knead for 15 minutes to prepare a billet. Press the billet into 230...

Embodiment 3

[0028] According to the ratio of mass content 10%, 1%, 5%, 6%, 15%, 45%, 18%, silicon powder, aluminum powder, alumina powder, flake graphite (75 μm) and silicon carbide coarse (1.43~ 2.5mm), medium (0.5-1.43mm), and fine particles (0.1-0.5mm) are weighed for later use. Among them, silicon powder, aluminum powder and alumina powder are co-ground for 20 to 30 minutes to prepare mixed fine powder for later use.

[0029] Mix the coarse, medium and fine particles of silicon carbide in the kneader for 4 minutes, then add 1% of the binder dextrin, 2% of the water-soluble amino resin and 2% of the solvent water and knead for 2 minutes to make the binder Form a uniform film on the surface of silicon carbide particles, then add graphite and knead for 8 minutes to ensure that the graphite is evenly coated on the surface of silicon carbide particles, and finally add the pre-prepared mixed fine powder and knead for 12 minutes to prepare a billet. Press the billet into 230×150×75mm with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com