Full silicon quantum dot nano laser and manufacturing method thereof

A nano-laser and silicon quantum dot technology, which is applied in the field of nano-photonic materials and new lasers, can solve the problems of difficult industrialization, high manufacturing cost, and low luminous efficiency of silicon materials, and achieve good stability and repeatability, and a wide processing range , good coherence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

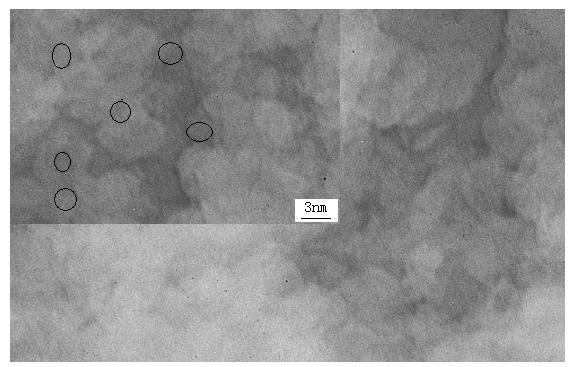

[0029] Embodiment 1: Prepare a stable all-silicon quantum dot nanolaser on the silicon surface with a nanosecond pulsed laser beam of 1064nm wavelength:

[0030] (1) Pretreatment: P-type doping is performed on the single crystal silicon wafer to form a silicon wafer with a resistivity of 2-20 ohm cm. The silicon oxide layer formed on the silicon surface in the air is removed with hydrofluoric acid, and alcohol and desiccant are used to remove the silicon oxide layer. Ionized water cleans the surface;

[0031] (2) Obtaining pulsed laser beams: use LD-pumped Nd:YAG solid-state lasers to obtain nanosecond pulsed lasers using acousto-optic Q-switching; use KTP crystals to achieve angle-matched frequency doubling, and adjust the fundamental mode output under the laser beam spot with a wavelength of 532nm ;Put the converging lens in a suitable position to converge the laser beam spot to the required line diameter; adjust the laser repetition rate to 3200 times / second, pulse width 30...

Embodiment 2

[0035] Embodiment 2: Application of all-silicon quantum dot nanolaser

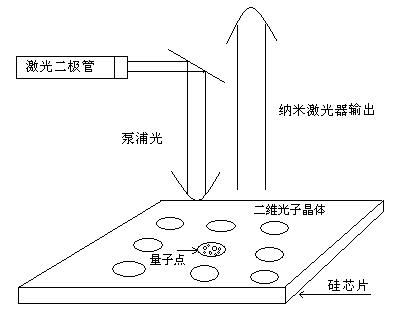

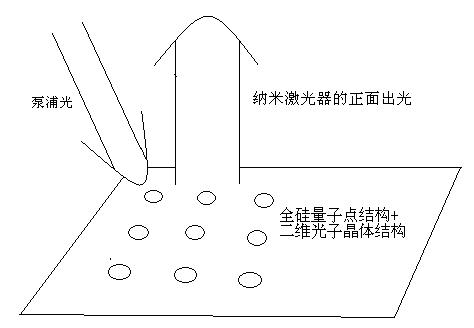

[0036] There are two options for assembling the all-silicon quantum dot nanolaser on the chip: one is to fix the optical path angle of the two-dimensional photonic crystal used as the resonance mode selection of the laser, select the optical path angle of the pump light and the outgoing light, and fix the mode output. The second is to change the optical path angle of the two-dimensional photonic crystal used as the resonance mode selection of the laser, by changing the optical path angle of the pump light and the outgoing light (such as Image 6 Shown), realize the pattern matching of wavelength division multiplexing.

[0037] As an optical interconnection application on a silicon chip, under the pumping of a short-wavelength laser, a strong stimulated light with good coherence in the visible region can be obtained (such as Figure 7 shown), which can be used for laser sources and propagation elements for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com