Method for preparing Ag2X film

A film and compound technology, applied in the field of Ag2X film preparation, can solve the problems of narrow scope of application and high cost, and achieve the effects of being environmentally friendly, cheap raw materials, and easy to obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

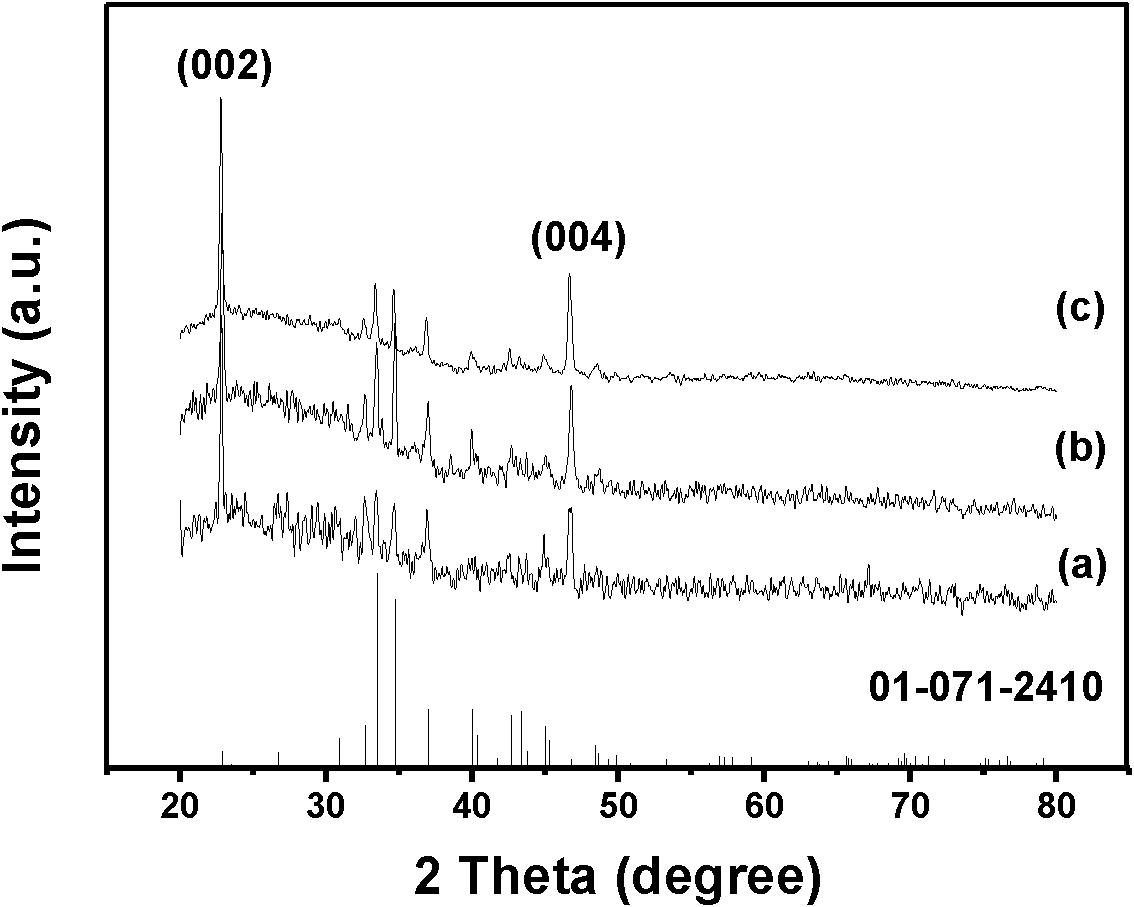

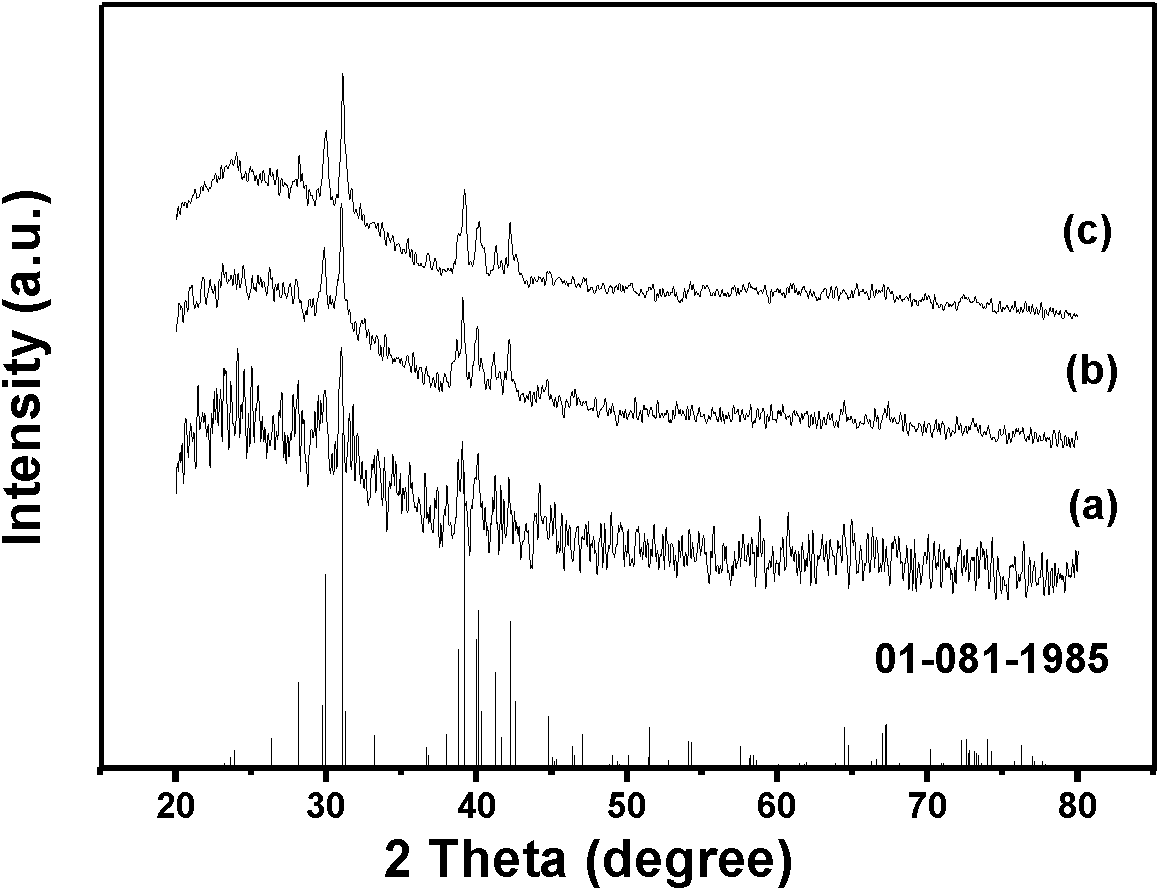

[0034] Synthesis of Silver Selenide Thin Films at Room Temperature

[0035] (1) Ingredients: add 100ml of deionized water to the beaker, put it into the stirring magnet and stir; weigh 0.340g of silver nitrate and 0.111g of selenium dioxide and add it to the beaker; weigh 1.4g of KOH and add it to the beaker, and continue stirring until The solution becomes transparent and clear; weigh 0.424g mercaptopropionic acid and add it to the beaker, and keep stirring; weigh 0.648g KBH 4 Slowly add to the beaker, stirring continuously during the addition; when all the KBH is added 4 After dissolving, take out the stirring magnet, add deionized water to 200ml; put in the glass substrate, and tilt it to form an angle of 30° with the bottom of the beaker;

[0036] (2) Constant temperature reaction: seal the mouth of the beaker with plastic wrap to prevent dust from entering, and let stand at room temperature for 24 hours;

[0037] (3) washing: the gained film is rinsed with deionized wat...

Embodiment 2

[0040] Silver Selenide Thin Films Synthesized in 50℃ Water Bath

[0041] (1) Ingredients: Add 100ml of deionized water into a beaker, put it into a stirring magnet and stir, weigh 0.340g of silver nitrate and 0.15g of sodium selenite into the beaker, then weigh 2.8g of KOH into the beaker, and continue stirring , until the solution becomes transparent and clear; then weigh 0.636g of mercaptopropionic acid and add it to the beaker, and keep stirring; finally weigh 1.296g of KBH 4 Slowly add to the beaker, stirring continuously during the addition. ;To be added all KBH 4 After dissolving, take out the stirring magnet, add deionized water to 200ml; put in the glass substrate, and tilt it to form an angle of 30° with the bottom of the beaker;

[0042] (2) Constant temperature reaction: seal the mouth of the beaker with plastic wrap to prevent dust from entering, put it into a constant temperature water bath at 50°C and let it stand for 12 hours.

[0043] (3) Washing: the obtain...

Embodiment 3

[0046] Silver Selenide Thin Films Synthesized in 70℃ Water Bath

[0047] (1) Ingredients: add 100ml of deionized water to the beaker, put it into the stirring magnet and stir; weigh 0.340g of silver nitrate and 0.166g of potassium selenite and add it to the beaker; weigh 5.6g of KOH and add it to the beaker, and continue stirring. Until the solution becomes transparent and clear; Weigh 1.06g of mercaptopropionic acid into the beaker and keep stirring; Weigh 1.728g of KBH 4 Slowly add to the beaker, stirring continuously during the addition; when all the KBH is added 4 After dissolving, take out the stirring magnet, add deionized water to 200ml; put in the glass substrate, and tilt it to form an angle of 30° with the bottom of the beaker;

[0048] (2) Constant temperature reaction: seal the mouth of the beaker with plastic wrap to prevent dust from entering, and put it in a constant temperature water bath at 70°C for 12 hours;

[0049] (3) washing: the gained film is rinsed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com