Method for actively controlling friction coefficient of metal friction pair in aqueous solution of surfactant

A surfactant and friction coefficient technology, used in non-electric variable control, friction lining, control/regulating systems, etc., can solve the problems of large electric power and lubricant consumption, difficult to meet engineering applications, and achieve the effect of avoiding electrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

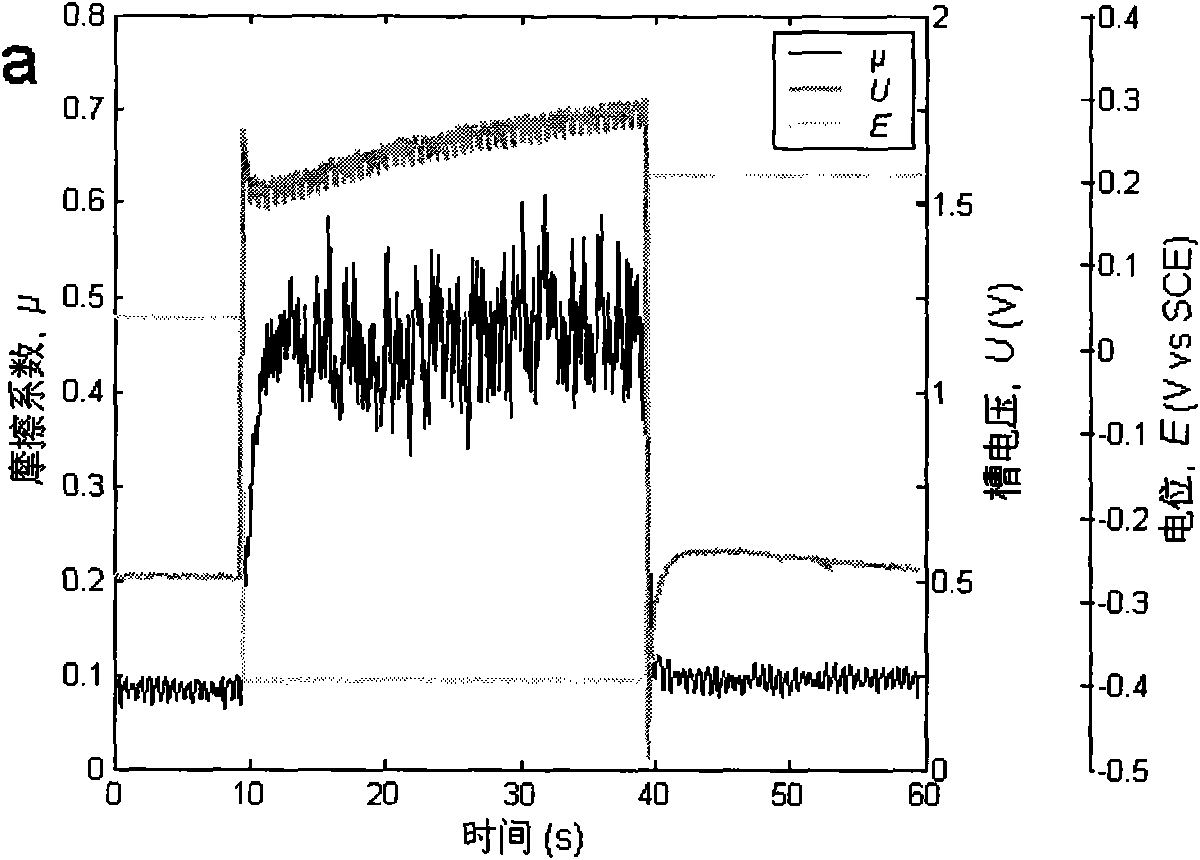

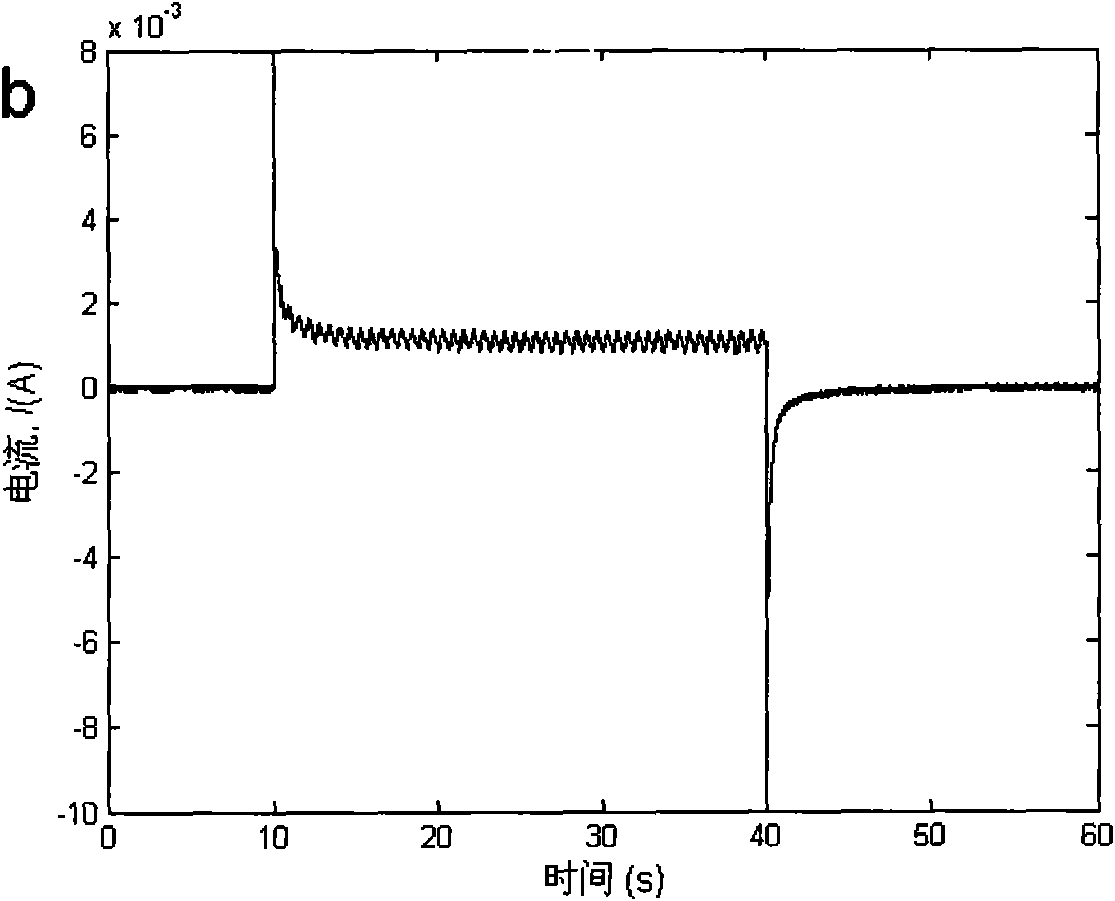

example 1

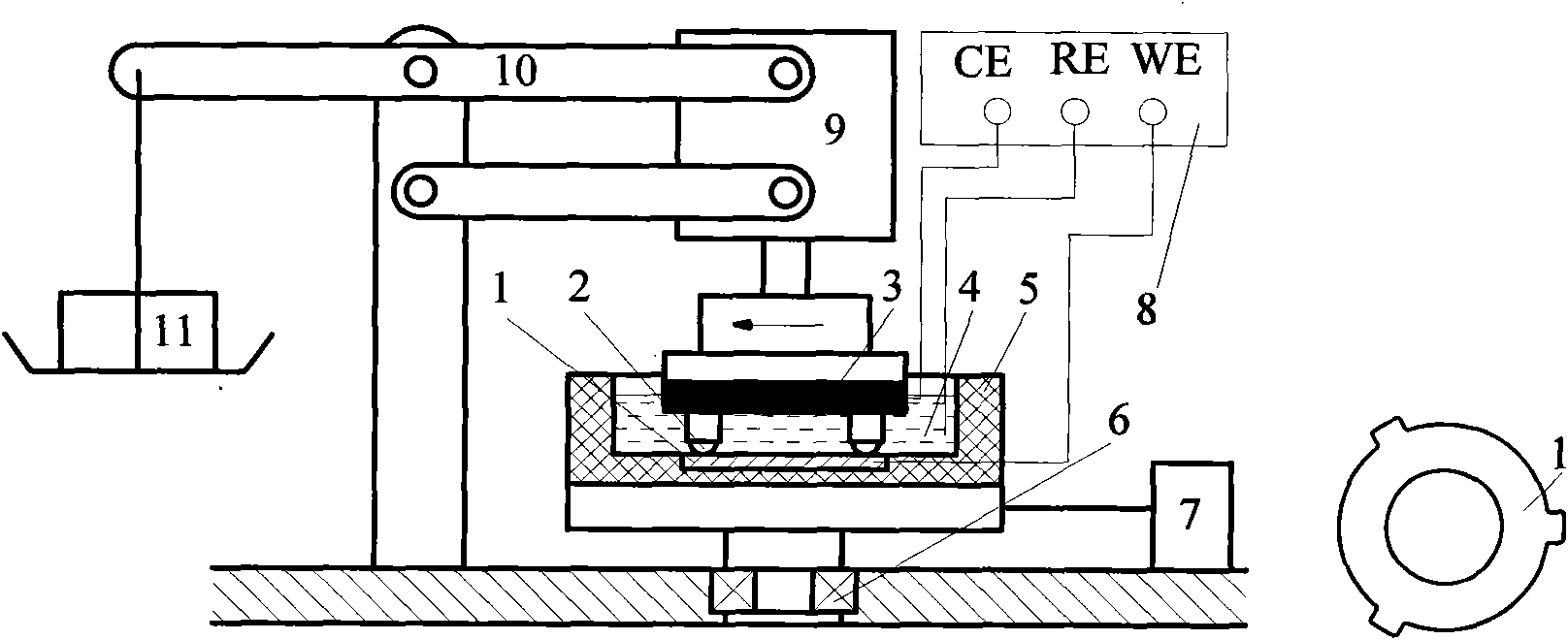

[0042] figure 1 It is a schematic diagram of a friction coefficient active control test device. The graphic marks are described as follows:

[0043] (1) metal disk, (2) ceramic ball, (3) graphite electrode, (4) lubricating fluid, (5) solution tank, (6) angular contact ball bearing, (7) force sensor, (8) electrochemical workstation (DC power supply), (9) adjustable speed motor, (10) lever, (11) weight

[0044] figure 1 The device shown is loaded by means of levers, and can be used for friction and wear tests in the form of ball / disk contact. One side of the friction pair (upper specimen) is ceramic balls (such as silicon nitride, zirconia, alumina) or metal balls 2 (such as Steel ball), the other side is metal (as stainless steel, aluminum alloy, titanium alloy, copper alloy etc.) disc 1. The friction pair is placed in an aqueous solution containing surfactants (such as sodium lauryl sulfate, potassium oleate, sodium stearate, sodium perfluorohexyl sulfonate, cetyltrimethyl...

example 2

[0064] In Example 2, the response of the friction coefficient of the zirconia ceramic / stainless steel friction pair to the control voltage was investigated by means of two electrodes.

[0065] Figure 4 is the experimental result of the friction coefficient changing with the cell voltage under a square wave control voltage. Figure 4 The response of the coefficient of friction of the zirconia / stainless steel friction pair in a two-electrode system to cell voltage control in 1 mM sodium dodecyl sulfate solution is shown. The results show that using the two-electrode control method can obtain similar effects to the three-electrode control method, which can simplify the composition of the control system.

example 3

[0066] Example 3 investigated the response of the coefficient of friction of the zirconia ceramic / stainless steel friction pair along with the series of square wave control potentials (such as Figure 5 shown), the specific implementation steps of the test are as follows:

[0067] The device and method of this group of experiments are the same as those in Example 1, except that the way of applying the control potential is changed to a series of square waves. Figure 5 It shows the response of the friction coefficient of zirconia / stainless steel friction pair to the change of the series square wave control potential in 0.5mM sodium dodecyl sulfate solution. The test results show that the rise and fall of the friction coefficient are almost the same as the change of the control potential Synchronous, its response and recovery time are within 0.5 seconds, which shows that the friction coefficient can follow the continuously changing square wave potential very well.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com