Composite anion exchange membrane for fuel cell and preparation method thereof

An anion exchange membrane and base membrane technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of complex raw materials, large conduction resistance, low electrical conductivity, etc., and achieve high quaternization degree, low preparation cost, and electrical conductivity. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

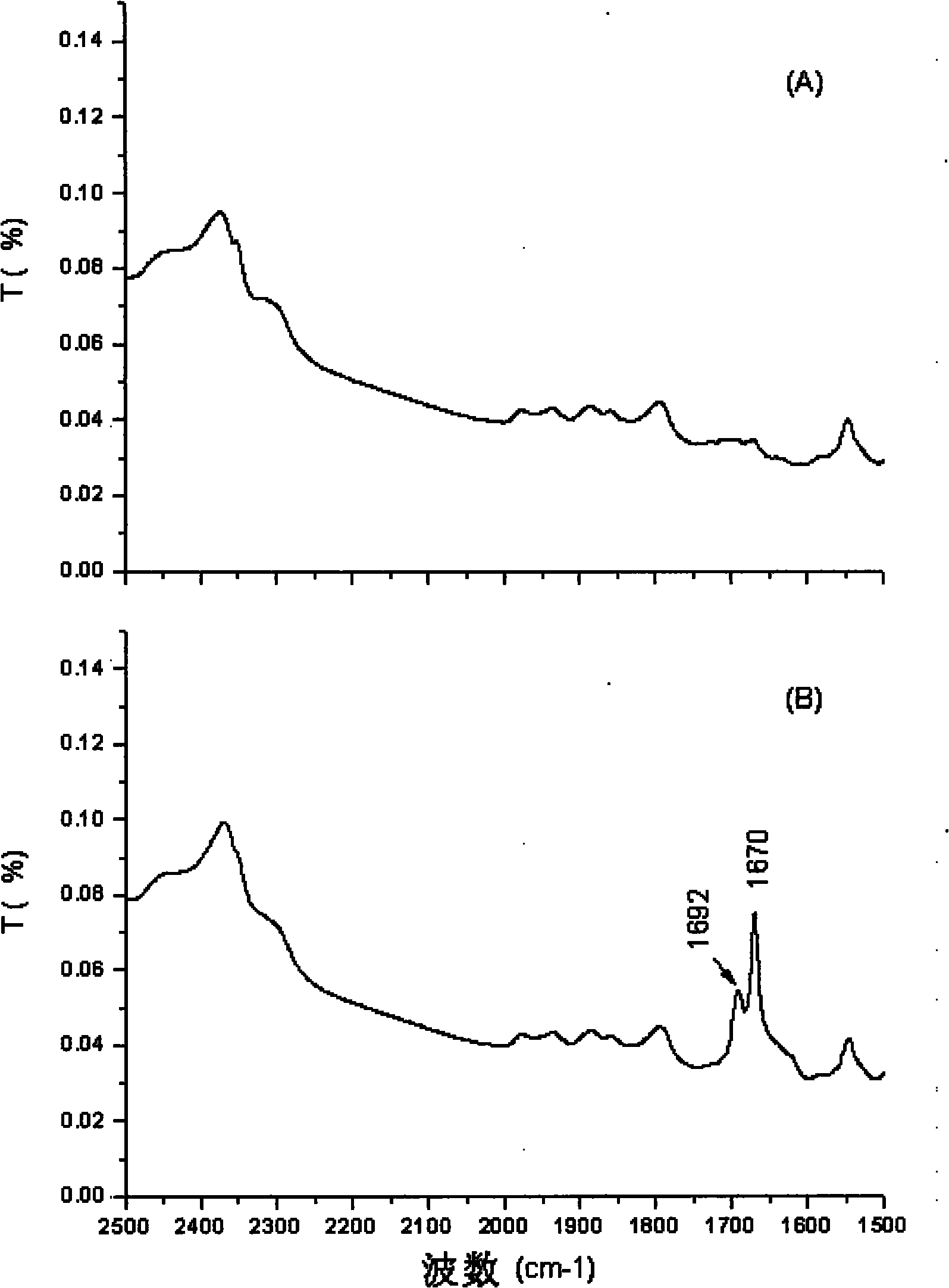

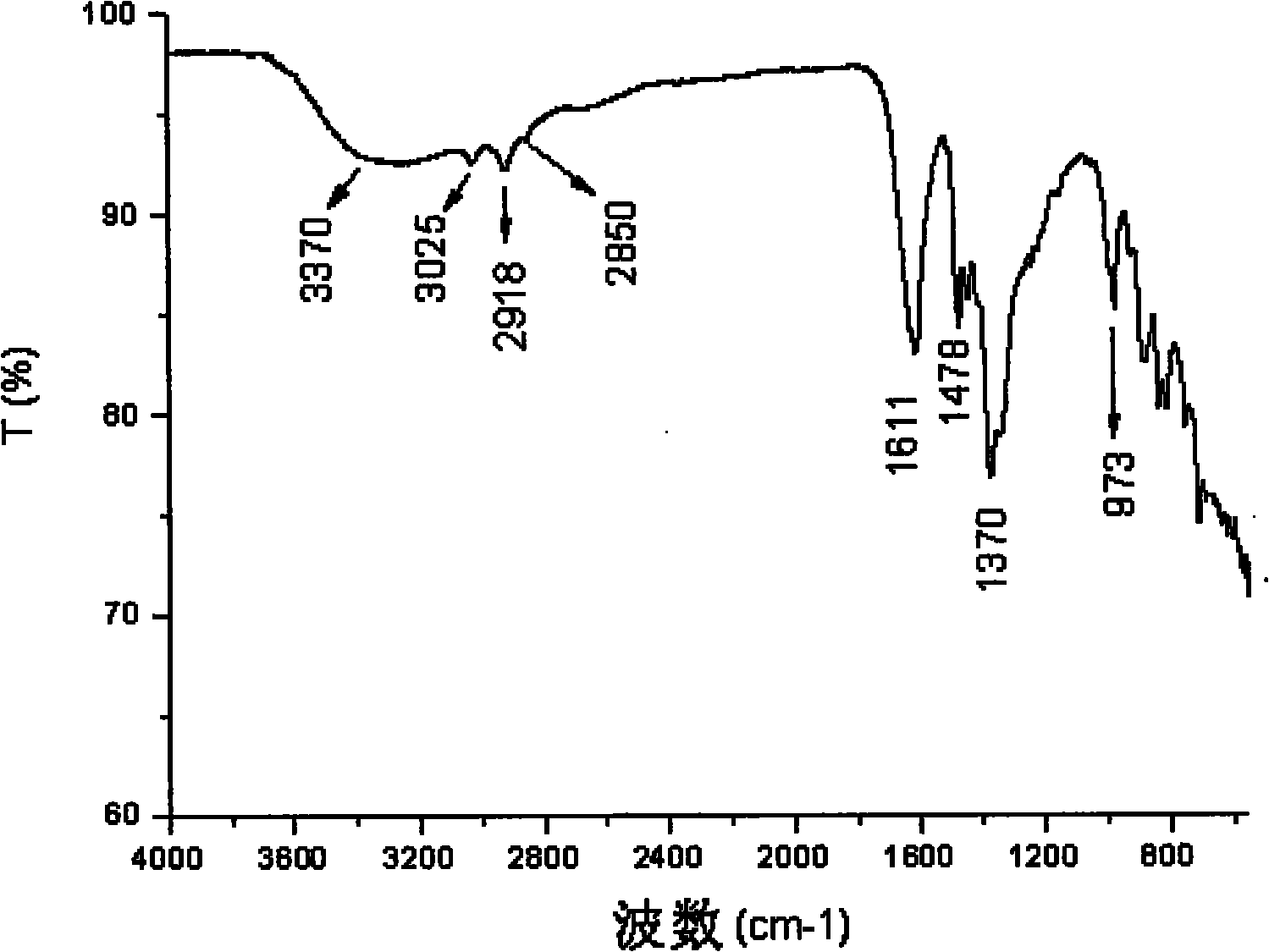

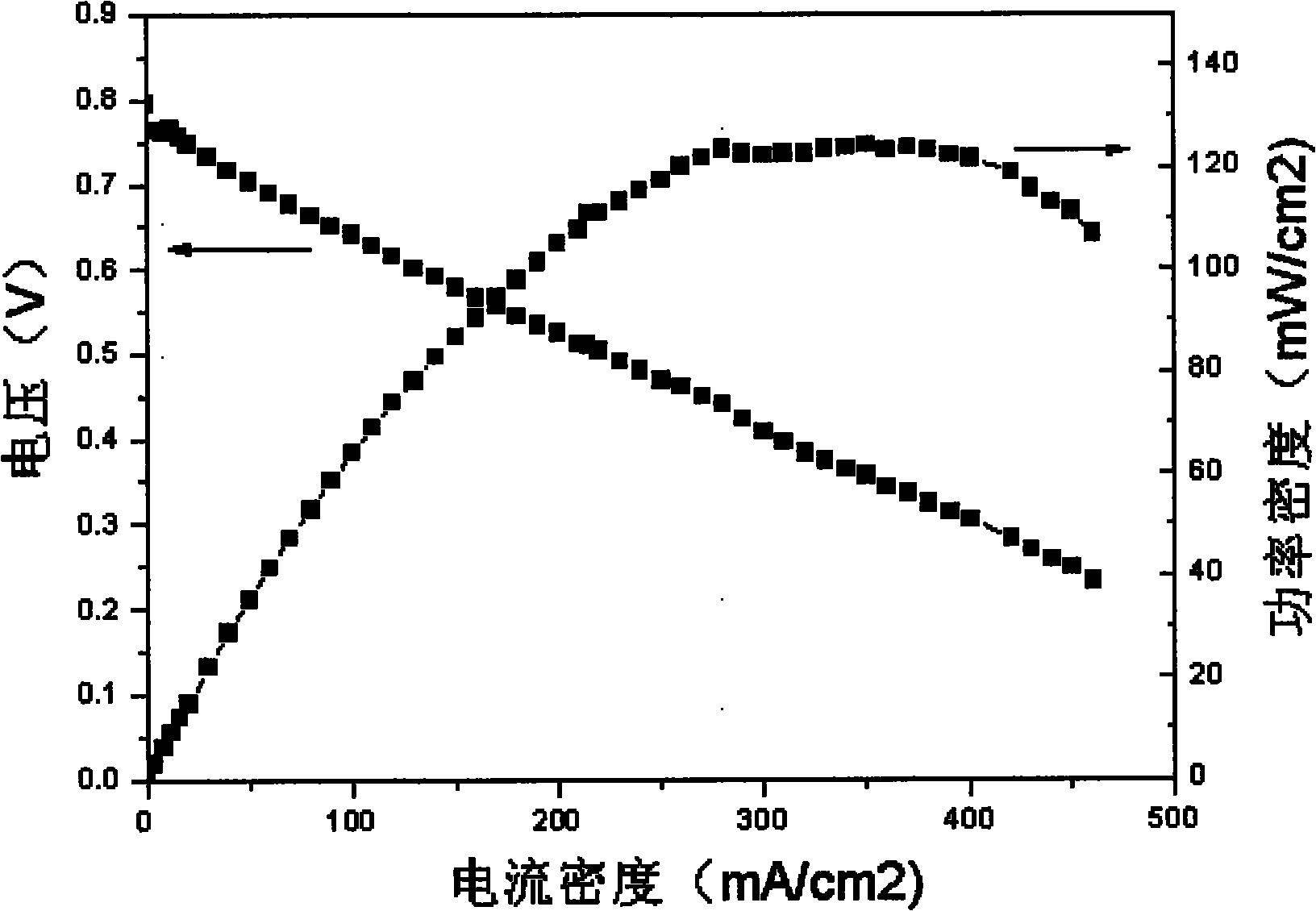

[0024]Mix chloromethylstyrene (VBC), divinylbenzene (DVB) and benzoyl peroxide (BPO), the molar percentage is VBC:DVB:BPO=97.8:1.2:1; the cut size is 6.5cm×7cm The PTFE porous membrane was placed in a 0.5M potassium hydroxide ethanol solution for 2 hours, taken out, rinsed with ethanol and dried naturally in the air; the pretreated PTFE membrane was placed in the monomer / initiator prepared above Immerse in the mixed solution of solvent for 60 hours. After taking it out, absorb the monomer solution on the surface with filter paper, spread it between two glass plates with a thickness of 7mm, and seal the gap between the glass plates with adhesive tape; the three-layer structure Put it on a heating plate, apply external pressure with a heavy object, and then heat it at 110°C for 3 hours; the obtained composite film is peeled off from the surface of the glass plate, and then soaked in an aqueous solution of trimethylamine with a mass fraction of 33% for 40 hours. After taking it ou...

Embodiment 2

[0030] Mix chloromethylstyrene (VBC), divinylbenzene (DVB) and benzoyl peroxide (BPO), the molar percentage is VBC:DVB:BPO=97.8:1.2:1; the cut size is 6.5cm×7cm The PTFE porous membrane was placed in a 0.5M potassium hydroxide ethanol solution for 2 hours, taken out, rinsed with ethanol and dried naturally in the air; the pretreated PTFE membrane was placed in the monomer / initiator prepared above Immerse in the mixed solution of solvent for 60 hours. After taking it out, absorb the monomer solution on the surface with filter paper, spread it between two glass plates with a thickness of 7mm, and seal the gap between the glass plates with adhesive tape; the three-layer structure Put it on a heating plate, apply external pressure with a heavy object, and then heat it at 110°C for 4 hours; the obtained composite film is peeled off from the surface of the glass plate, and then immersed in an aqueous solution of trimethylamine with a mass fraction of 33% for 48 hours, taken out and u...

Embodiment 3

[0033] Mix chloromethylstyrene (VBC), divinylbenzene (DVB) and benzoyl peroxide (BPO), the molar percentage is VBC:DVB:BPO=97.8:1.2:1; the cut size is 6.5cm×7cm The PTFE porous membrane was placed in a 0.5M potassium hydroxide ethanol solution for 2 hours, taken out, rinsed with ethanol and dried naturally in the air; the pretreated PTFE membrane was placed in the monomer / initiator prepared above Immerse in the mixed solution of solvent for 60 hours. After taking it out, absorb the monomer solution on the surface with filter paper, spread it between two glass plates with a thickness of 7mm, and seal the gap between the glass plates with adhesive tape; the three-layer structure Put it on a heating plate, apply external pressure with a heavy object, and then heat it at 110°C for 4 hours; the composite film obtained is peeled off from the surface of the glass plate, and then it is washed with an aqueous solution of trimethylamine and tetramethylethylenediamine with a mass fraction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com