Method for detecting volatile organic compound in cigarette filter

A technology for organic compounds and determination methods, which is applied in the field of determination of thirteen volatile organic compound residues in cigarette filters, can solve the problems of high sensitivity, cumbersome pretreatment, expensive instruments, etc., and achieves good repeatability and optimization. Instrument detection conditions, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0052] 1. Reagents and instruments:

[0053] Standard samples: vinyl acetate, butanone, ethyl acetate, isopropyl acetate, benzene, n-propyl acetate, 4-methyl-2-pentanone, toluene, n-butyl acetate, ethylbenzene, p-(m) -Xylene, o-xylene, cyclohexanone; internal standard: fluorobenzene; glyceryl triacetate, ultrapure water, sodium chloride, and the above reagents are of analytical grade.

[0054] PerkinElmer Clarus 600 GC gas chromatograph; PerkinElmer Clarus 600 MS mass spectrometry detector; PerkinElmer Turbomatrix HS-40 headspace autosampler; AE163 electronic balance (sensitivity: 0.0001 g) (Mettler, Switzerland).

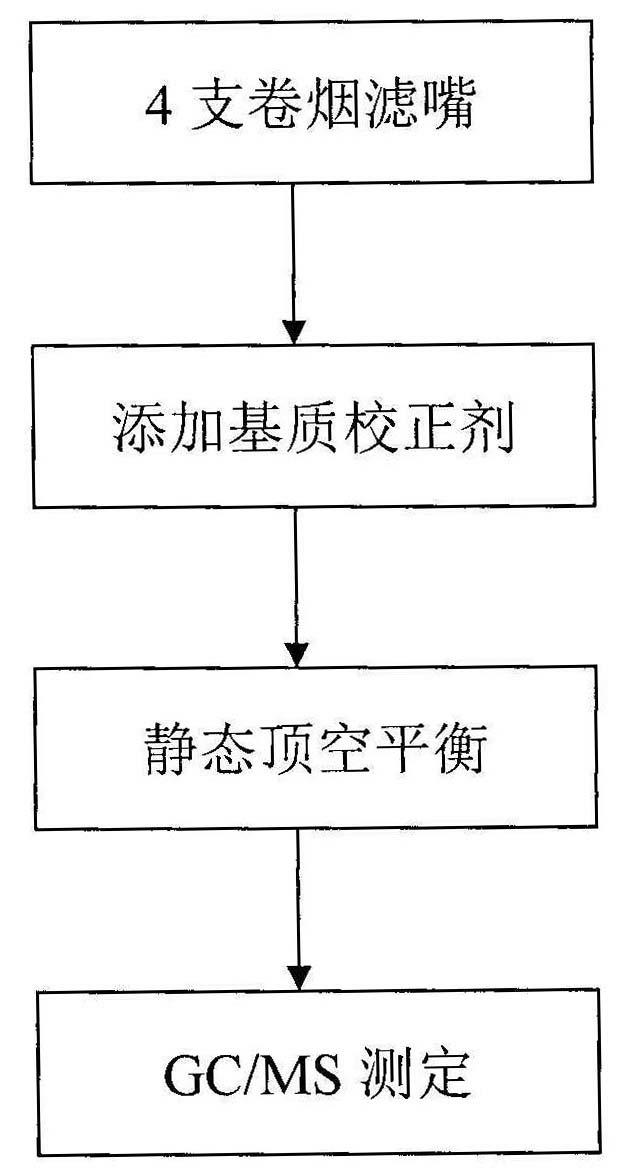

[0055] 2. Sample handling:

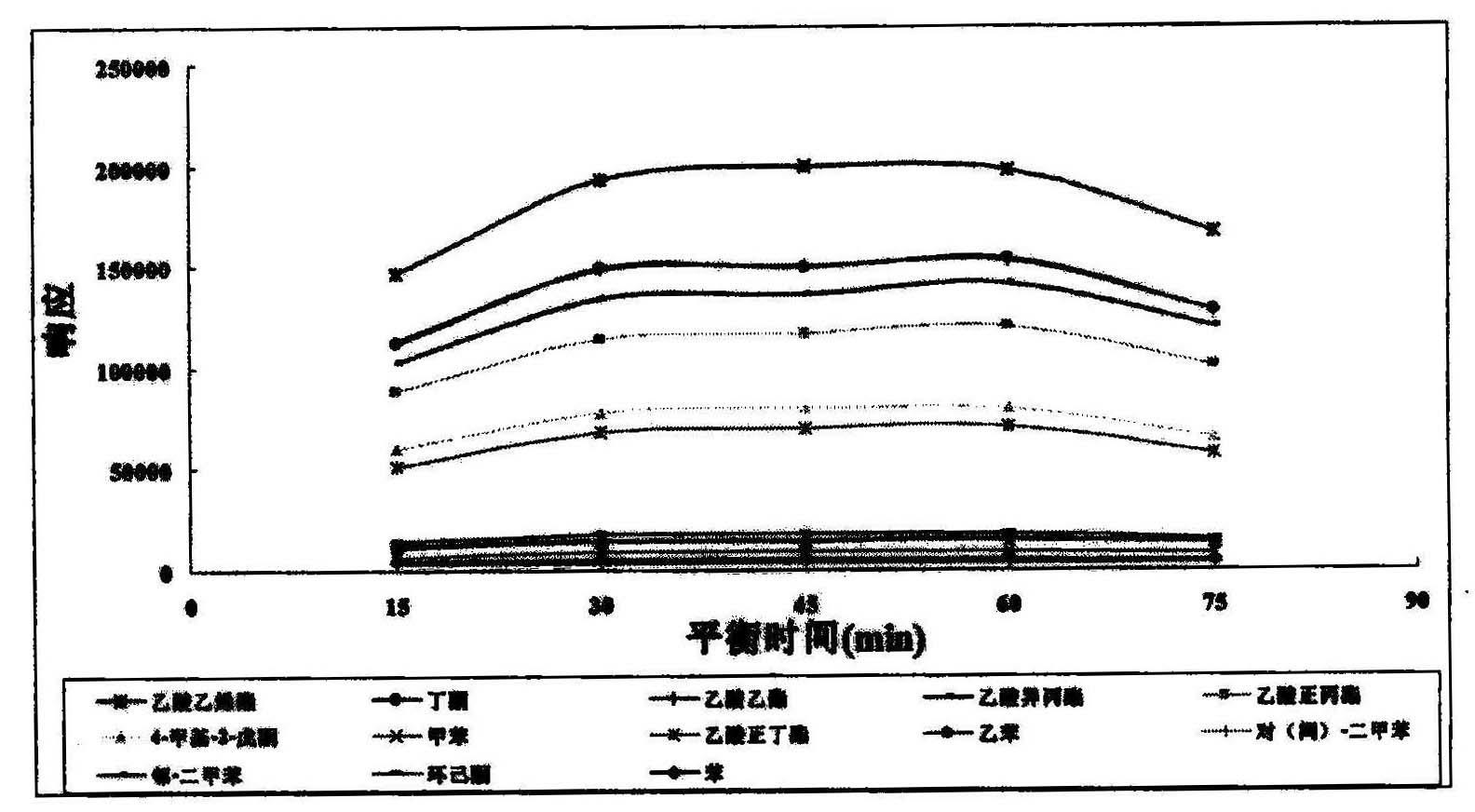

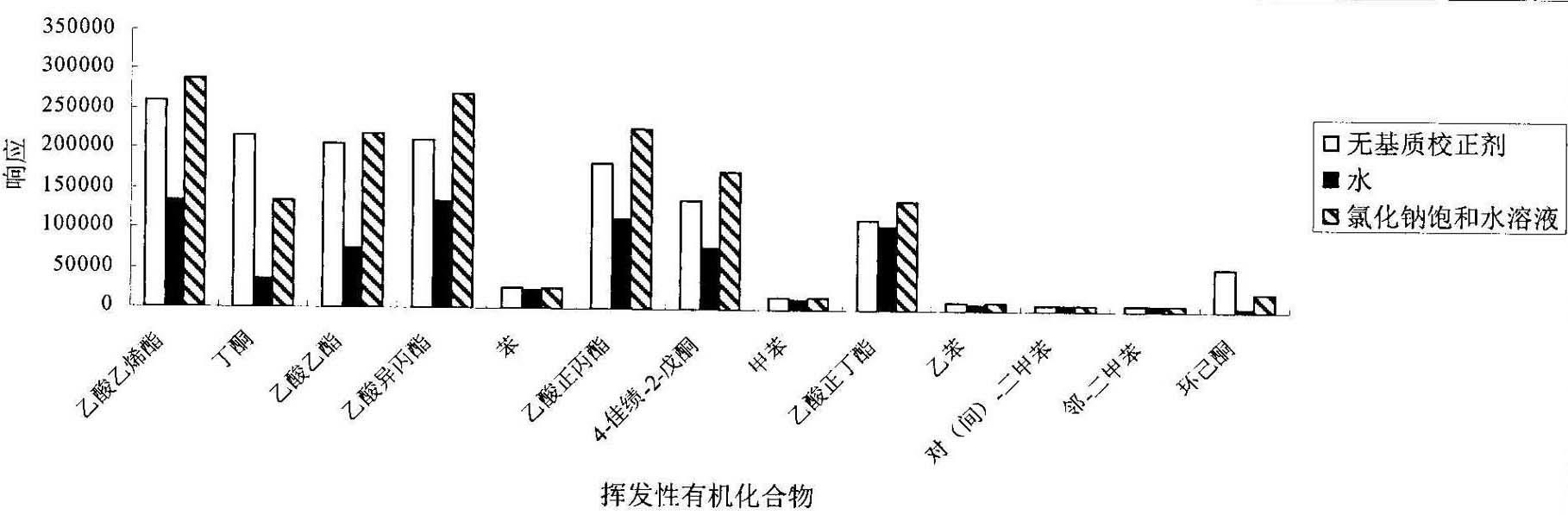

[0056] Open a pack of cigarettes, take out four cigarettes at random, break off the four cigarette filters along the interface between the filter tip and the cigarette, place the four filters vertically on the bottom of the 22.5mL special headspace bottle, and add them accurately with a pipette gun 8mL matrix calibrator and 20μL int...

example 2

[0069] The specific steps are as described in Example 1. Another cigarette sample B was selected, and the content of volatile organic compounds in the filter sample was measured in Table 6.

[0070]

example 3

[0072] The specific steps are as described in Example 1. Another cigarette sample C was selected, and the content of volatile organic compounds in the filter sample was measured in Table 7.

[0073]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com