Production process for preparing hot reaction shrimp-taste essence with macrobrachium shells

A thermal reaction and shrimp shell technology, applied in the field of food processing, can solve the problems of thin flavor, unprominent aroma, and lack of thermal reaction process of shrimp paste, and achieve the effects of rich flavor, low cost and rich amino acid composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0027] [Implementation Case 1] Laboratory preparation of heat-reactive shrimp flavor essence

[0028]1kg of fresh shrimp shells, the moisture content is about 78%, put the shrimp shells into a 5L large beaker, add about 2.5L of deodorization liquid, the composition is 0.15% acetic acid + 0.15% sodium chloride + 0.15% sodium sulfite, soak for 2 hours , drained and washed 3 times with clear water, aired indoors for 10 hours, and dried in a vacuum oven to obtain 216g of dried shrimp shells. Use a small hammer mill to pulverize, and use a 60-mesh sieve to collect the fine powder for subsequent use.

[0029] Take 100g of the above-mentioned fine powder, put it into a large mouth round bottom flask with a stopper, add 100mL of 95°C hot water, stir and mix quickly with a glass rod, place the plug in a boiling water bath for 5min, take it out, and quickly place it in tap water to cool to room temperature.

[0030] Add 300mL of water, and stir in a 60°C water bath. Add 0.3g of papain...

Embodiment example 2

[0032] [Implementation Case 2] Small-scale preparation of heat-reacted shrimp flavor essence

[0033] 50kg of fresh shrimp shells, manually cleaned to remove foreign matter. Put the shrimp shells in the washing tank, add about 150L of deodorizing liquid, its composition is 0.05% acetic acid + 0.05% sodium chloride + 0.05% sodium sulfite, soak for 3 hours, take out and drain, and wash twice with water. After being dried by centrifugal dehydration equipment, then use a vacuum drying oven to dry at 75°C to obtain dried shrimp shells, which are pulverized by a roller mill and sieved with 40 meshes to collect fine powder, about 10kg.

[0034] Add the above-mentioned fine powder into a 100L stirred reactor, add 15kg of 100°C boiling water, stir and mix well, seal it, and introduce a small amount of water vapor, maintain the temperature at 100°C for about 2min, open the exhaust valve, and quickly cool down to 40°C by vacuum pumping. ℃ or so.

[0035] Add 50 kg of deionized water, a...

Embodiment example 3

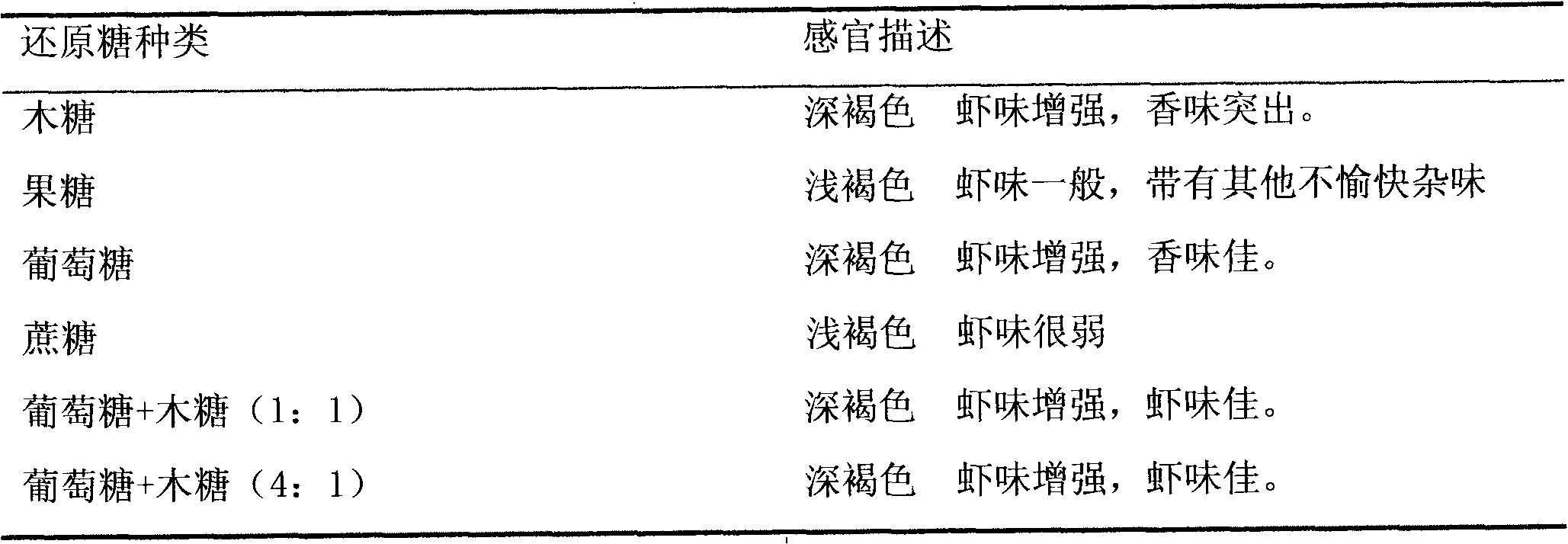

[0038] [Implementation Case 3] Effects of Adding Types of Reducing Sugar on Product Sensory

[0039] Different types of reducing sugars produce different aroma substances and have different reaction speeds. Generally, the rate of pentose is faster than that of hexose, and that of monosaccharide is faster than that of disaccharide. Combined with the price factor of sugar, this experiment selects xylose, fructose, glucose, sucrose to react with the enzymatic solution, and evaluates the effects of the four sugars by direct description method . The experimental process is the same as "Example 1", except that the reducing sugar added in each batch is the variety shown in Table 1. Through comparison, it is determined that xylose and glucose have a better effect in participating in the reaction, so these two sugars are selected for the preparation of the reaction essence. According to the research, good shrimp fragrance can be obtained by adding glucose and xylose at a ratio of 4:1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com