Xanthobacter sp. D7 capable of degrading dioxane and application thereof

A dioxane and yellow technology, applied in the direction of bacteria, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problem that there are no yellow bacteria to degrade dioxane, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

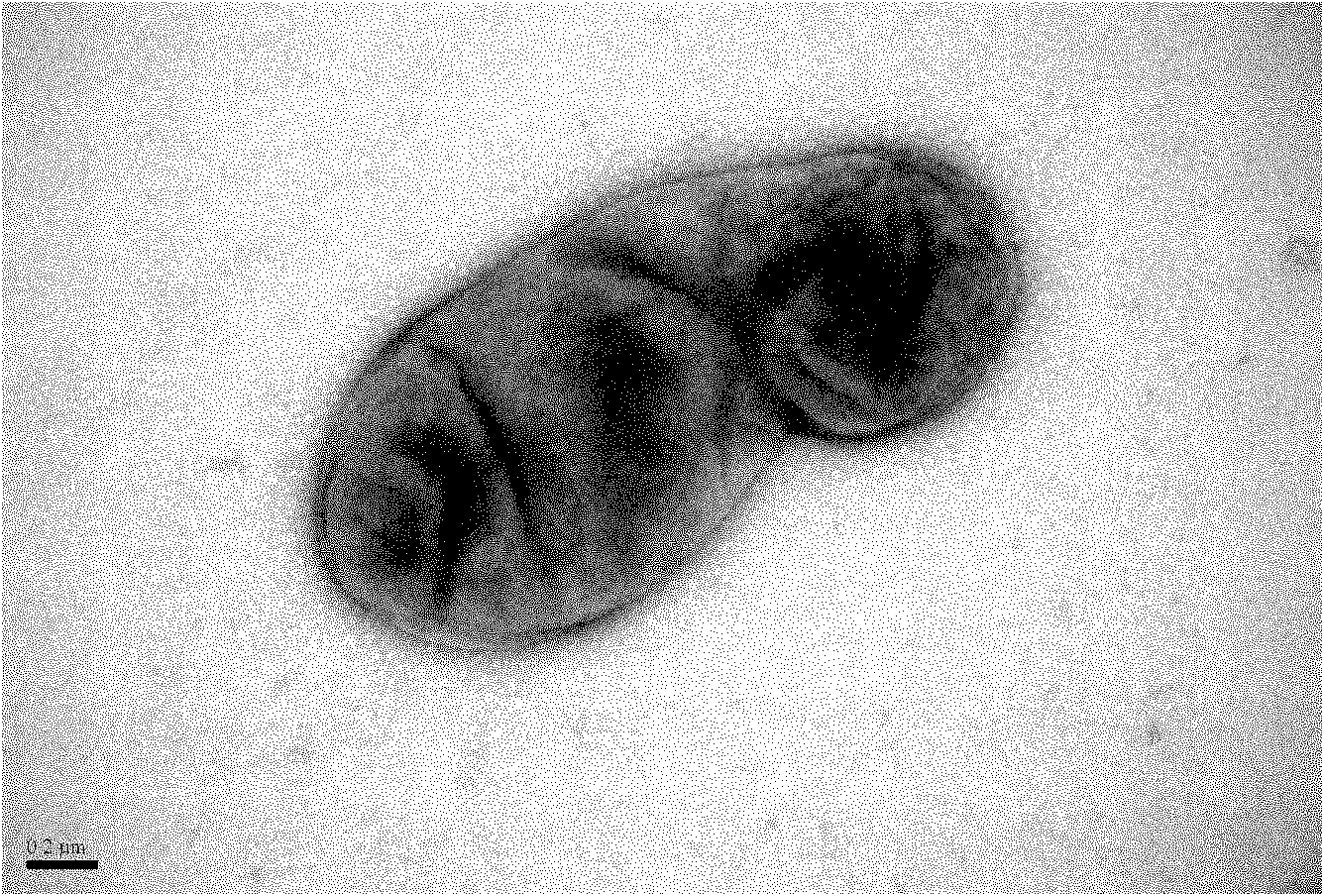

[0023] Isolation and Identification of Xanthobacter sp.D7

[0024] (1) Sample collection and domestication

[0025] The activated sludge from the sewage treatment tank of a chemical plant in Zhejiang was collected on site, and dioxane was used as the only carbon source and energy source for domestication and enrichment. Several months later, the activated sludge was inoculated into a 250mL sealed saline bottle containing 50mL of BSM medium, and dioxane was used as the only carbon source and energy source to continue cultivation and enrichment. The experiment requires a constant temperature (30±1°C) and is kept under aerobic conditions.

[0026] BSM was formulated as follows: 4.5g Na 2 HPO 4 12H 2 O, 1.0g KH 2 PO 4 , 1.5g NH 4 Cl, 0.2g MgSO 4 ·7H 2 O, 0.023g CaCl 2 , 1mL trace element mother solution, water to make up to 1000mL.

[0027] Concentration composition of trace element mother liquor: FeSO 4 ·7H 2 O 1.0g / L, CuSO 4 ·5H 2 O 0.02g / L, H 3 BO 3 0.014g / L, ...

Embodiment 2

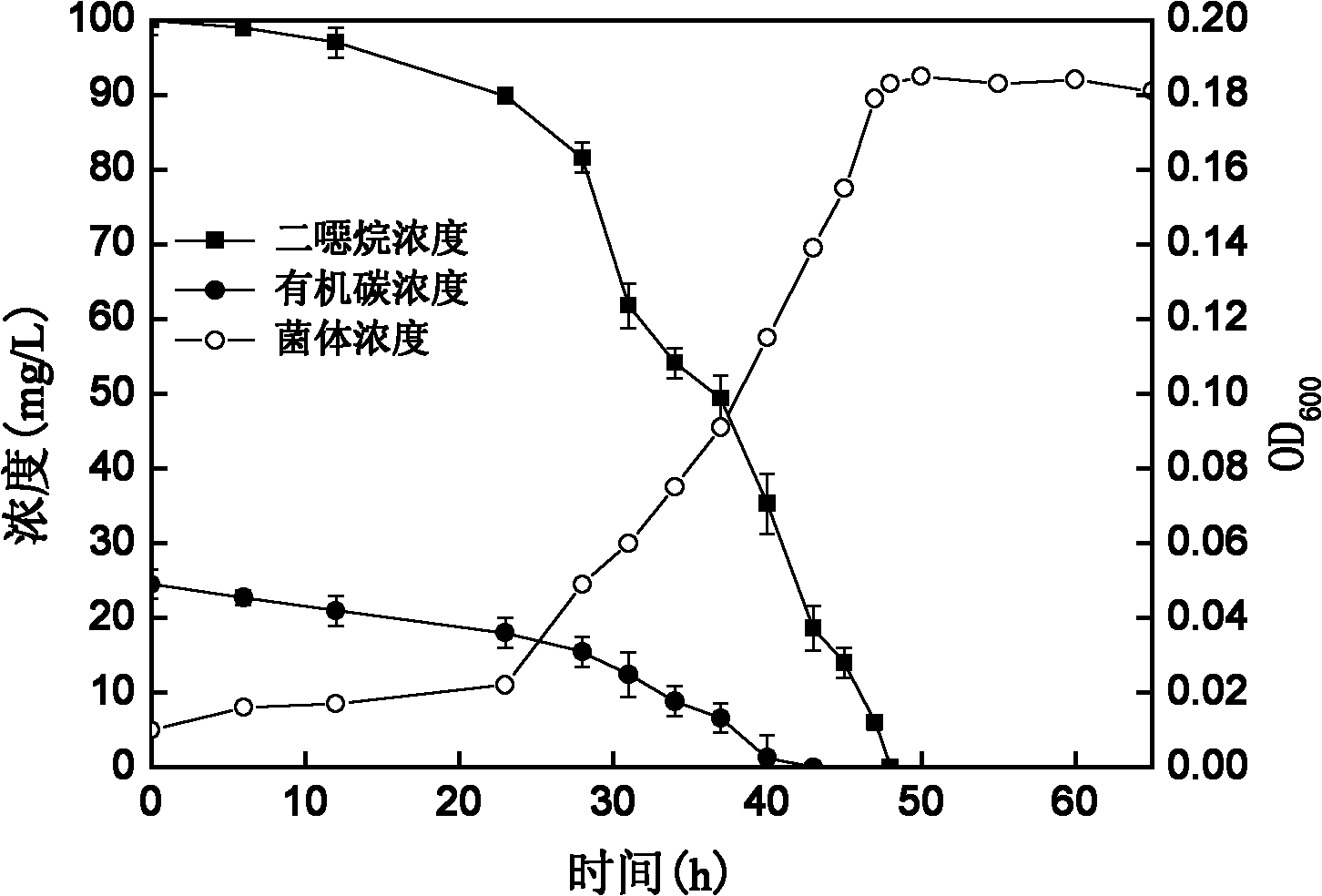

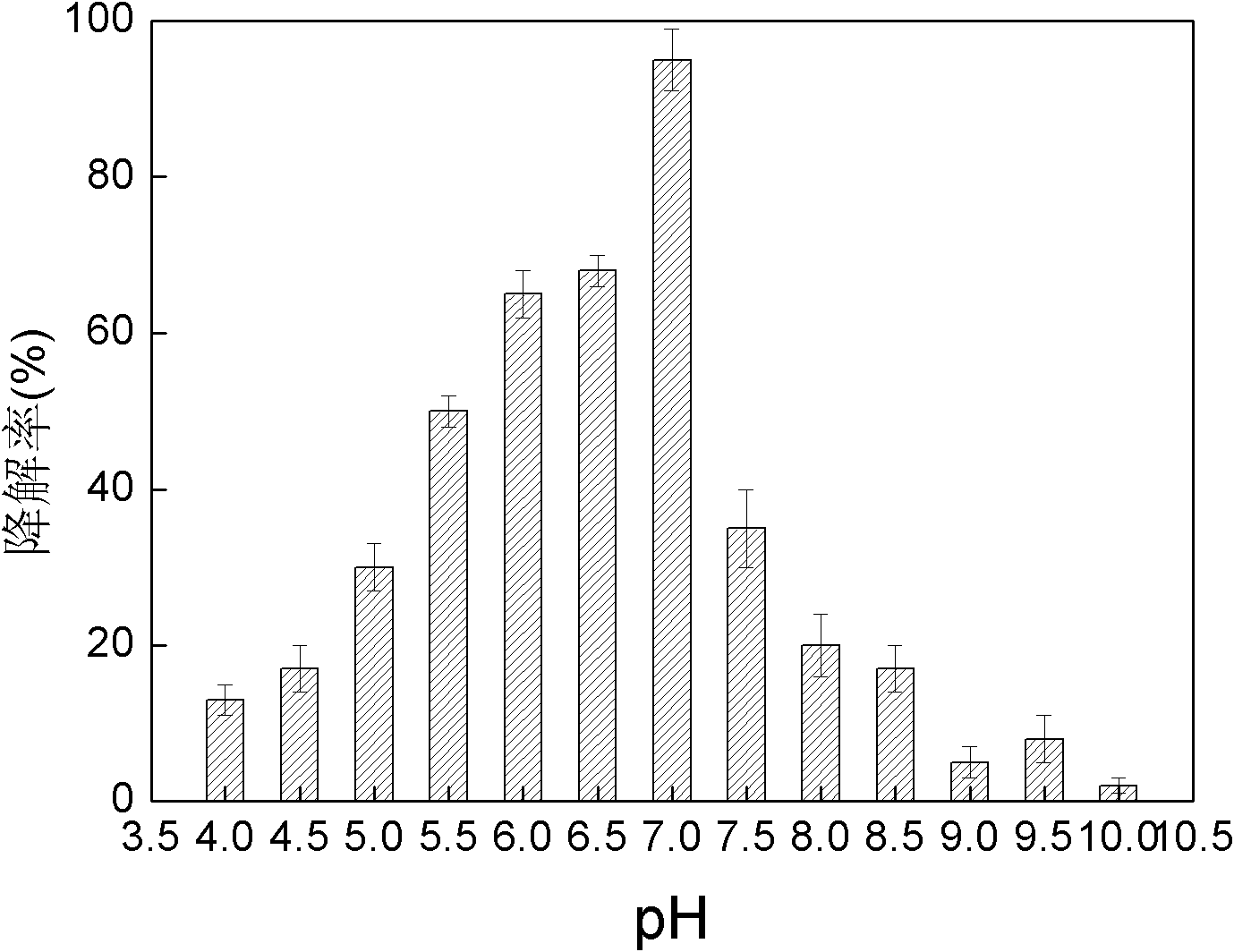

[0033] Example 2: Performance of Xanthobacter sp.D7 (CCTCC NO: M 2010225) in degrading dioxane

[0034] Seed liquid preparation: D7 was inoculated on the R2A slant and cultured for 3 days, then inoculated from the slant into BSM medium containing 100mg / L dioxane and cultured for 2 days, centrifuged at 1200rpm / min for 5min, discarded the supernatant, and washed with normal saline Rinse and wash the bacteria twice to make a bacterial suspension, which is the seed solution for the experiment.

[0035] Using dioxane as the sole carbon source of Xanthobacter sp.D7, inoculate the bacterium from the seed liquid to 50mL BSM medium, so that the initial bacterial cell concentration (in terms of OD) is 0.01; add dioxane to make the initial dioxane concentration 100mg / L. Put it into a shaker with a temperature of 30°C and a rotation speed of 160r / min for cultivation, and take samples at regular intervals, see the results figure 2 . With the prolongation of time, the bacterial cell con...

Embodiment 3

[0040] Embodiment 3: Xanthobacter sp.D7 purifies dioxane waste water

[0041] Inoculate Xanthobacter sp.D7 bacteria solution in the biotrickling filter tower for continuous treatment at a concentration of 100mg / m 3 of dioxane exhaust gas. After 25 days of film-hanging start-up, the purification efficiency of the dioxane waste gas of the bio-trickling filter reached over 93%, and the system has been running stably since then.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com