Organic light emitting diode

A light-emitting diode, organic technology, applied in the direction of light-emitting materials, electrical components, circuits, etc., can solve problems such as easy quenching of carriers, OLED device degradation, exciton quenching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

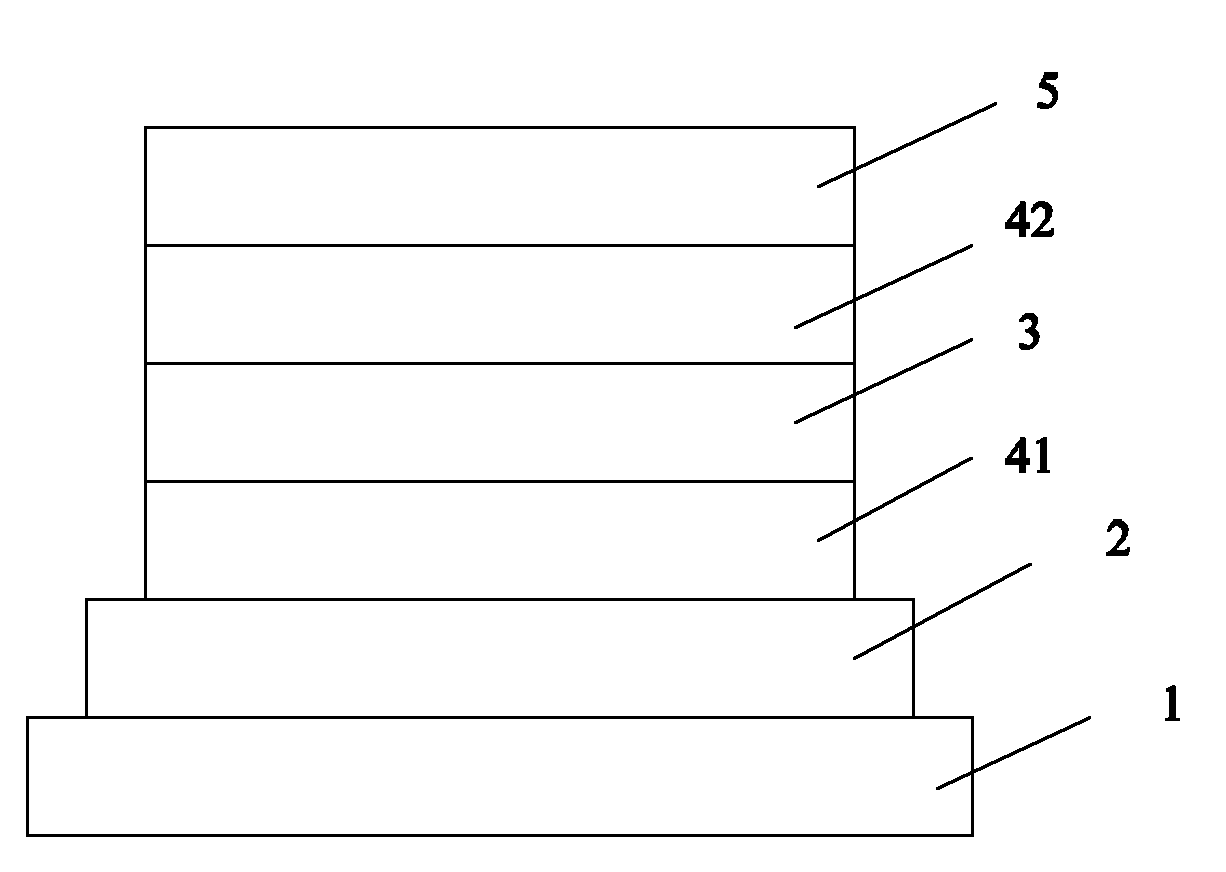

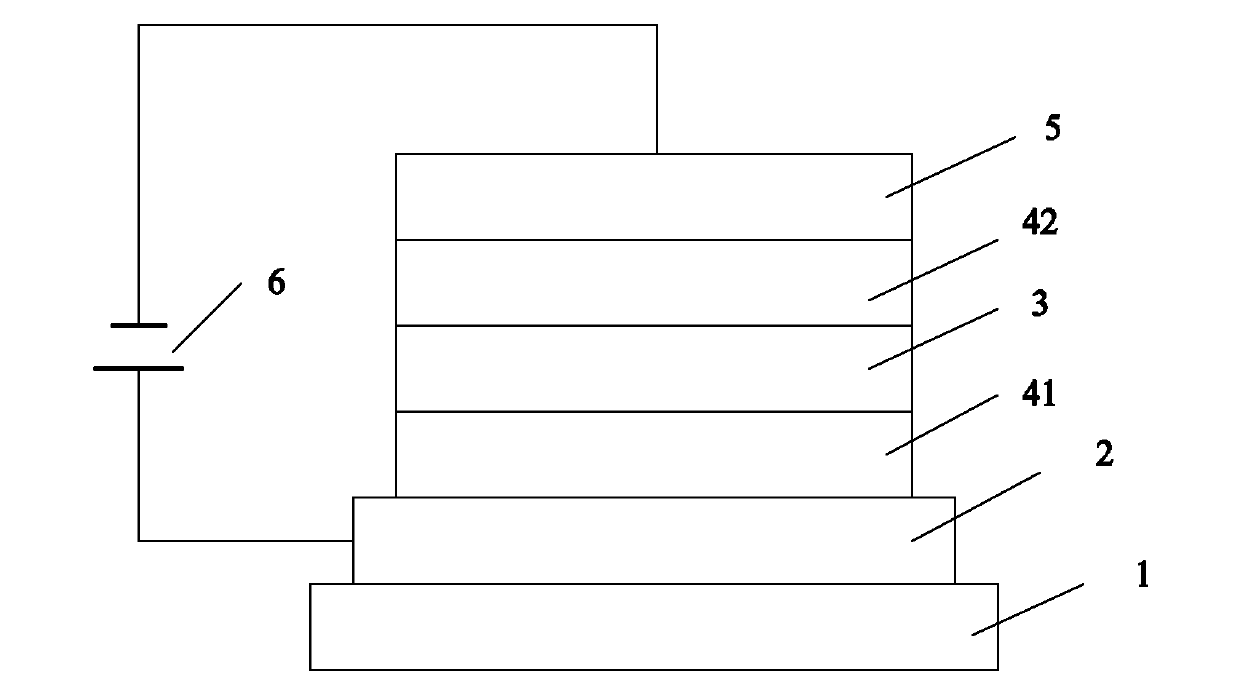

[0050] The preparation method of the organic light emitting diode provided by the present invention is

[0051] The substrate is first dried, and an anode material is used to photolithography electrodes on the dried substrate to obtain a first electrode, that is, an anode, and the anode material is indium tin oxide. Then an organic semiconductor heterojunction unit, a light emitting unit and a second electrode are sequentially formed on the first electrode. The forming method is preferably vacuum evaporation, photolithography or sputtering, and vacuum evaporation is preferably used in the present invention, because vacuum evaporation can prepare each unit with uniform thickness and very thin. In the present invention, the substrate containing the first electrode is placed in a vacuum evaporator, and an organic semiconductor heterojunction unit, a light-emitting unit and a second electrode are sequentially evaporated on the first electrode. The degree of vacuum in the vacuum e...

Embodiment 1

[0053] First, the anode indium tin oxide layer is photolithographically formed into thin strip electrodes, then cleaned, blown dry with nitrogen gas, treated with oxygen plasma for 2 minutes, and then transferred to the vacuum coating system until the vacuum degree reaches 5×10 -4 At Pascal, the first organic semiconductor heterojunction unit, the light emitting unit, the second organic semiconductor heterojunction unit and the cathode are sequentially vapor-deposited on the ITO anode, wherein the first organic semiconductor heterojunction unit adopts C 60 and pentacene formed by evaporation one by one; C 60The thickness of the pentacene is 20nm, and the thickness of the pentacene is 10nm; the hole injection layer in the light-emitting unit is made of MoO 3 , the thickness is 1nm; the hole transport layer is TCTA, the thickness is 70nm; the light emitting layer is (ppy) 2 Ir(acac) doped TCTA with a thickness of 20nm; the electron transport layer uses TPBi with a thickness of ...

Embodiment 2

[0060] First, the anode indium tin oxide layer is photolithographically formed into thin strip electrodes, then cleaned, blown dry with nitrogen gas, treated with oxygen plasma for 2 minutes, and then transferred to the vacuum coating system until the vacuum degree reaches 5×10 -4 At the same time, organic semiconductor heterojunction 1, light-emitting unit, organic semiconductor heterojunction 2, and cathode are sequentially deposited on the ITO anode, wherein organic semiconductor heterojunction 1 adopts C 60 and ZnPc formed by evaporation one by one; C 60 The thickness of ZnPc is 20nm, and the thickness of ZnPc is 15nm; the hole injection layer in the light-emitting unit is made of MoO 3 , the thickness is 1nm; the hole transport layer is TCTA, the thickness is 70nm; the light emitting layer is (ppy) 2 Ir(acac) doped TCTA with a thickness of 20nm; the electron transport layer uses TPBi with a thickness of 40nm; the electron injection layer uses Li 2 CO 3 , with a thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com