Ultraviolet (UV)-curing plasma display circuit protective agent with silver ion migration resistance and preparation method thereof

A plasma display, circuit protection technology, applied in coatings, epoxy coatings, polyurea/polyurethane coatings, etc., can solve the problem of crosslinking density, flexibility, high adhesion, inability to achieve plasma display, and long molding cycle. and other problems, to achieve the effect of not easy silver ion migration, good temperature shock resistance and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

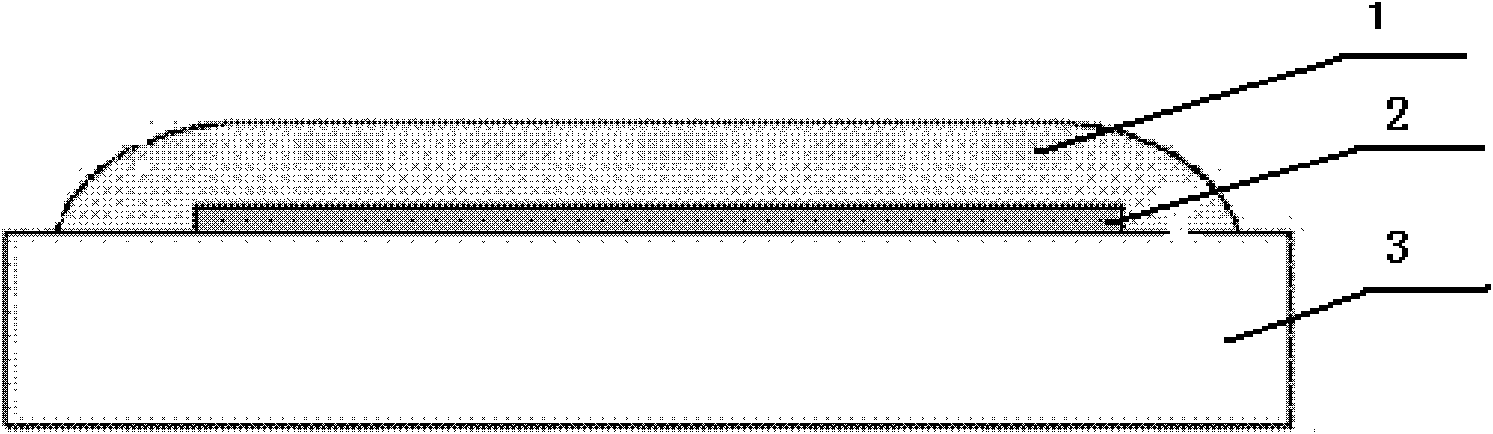

Image

Examples

preparation example Construction

[0031] The preparation method of the UV curing anti-silver ion migration type plasma display circuit protective agent related to the present invention comprises the following steps:

[0032] (1) Mix 10-60wt% photoreactive monomer and 0.05-1wt% silver ion absorbent in the total system at room temperature, and prepare a uniform solution system by three-roll grinding or ultrasonic dispersion;

[0033] (2) Adding 2-8wt% photoinitiator and 0.1-5wt% processing aid to the solution system prepared in step (1), fully stirring or ultrasonic dispersion until completely dissolved;

[0034] (3) At 30-70°C, add (meth)acrylic acid-modified prepolymer accounting for 30-80wt% of the total system to the solution system prepared in step (2), stir thoroughly, and filter to obtain ultraviolet light Curing silver ion migration resistant plasma display circuit protection agent.

[0035] It should be noted that, without departing from the gist of the present invention, the photocurable resin compone...

Embodiment 1

[0037]

[0038]

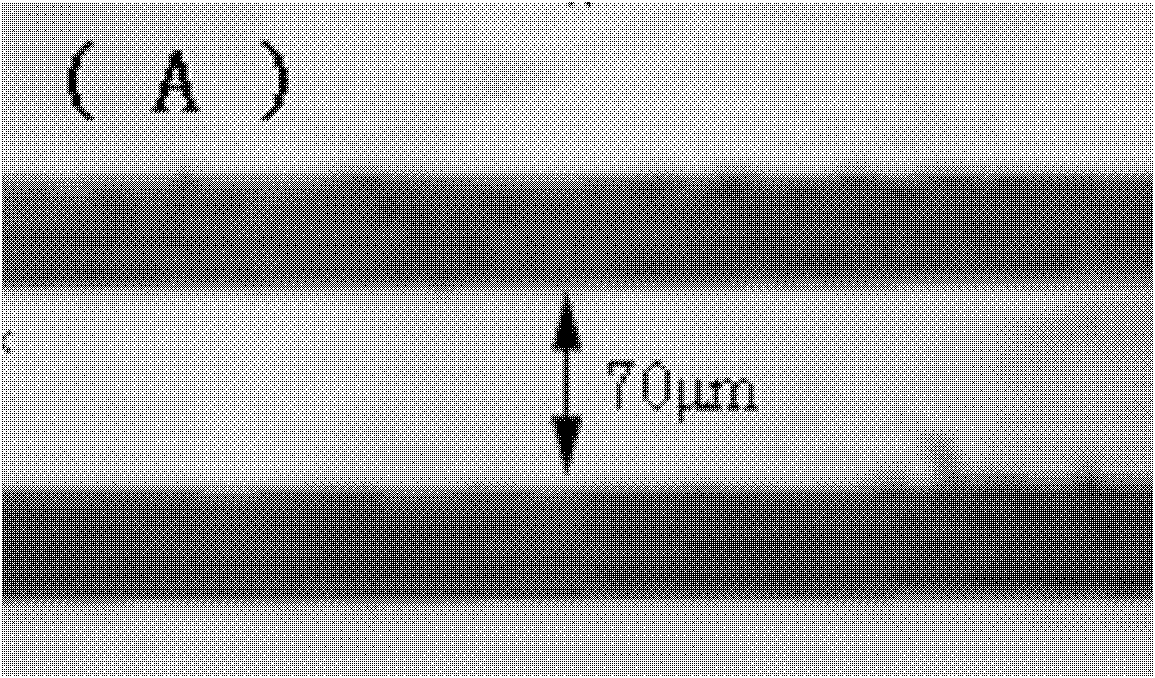

[0039] According to the preparation method of the above-mentioned ultraviolet light curing silver ion migration resistant plasma display circuit protective agent, an ultraviolet light curing silver ion migration resistant plasma display circuit protective agent is prepared. Coated on silver electrodes with a spacing of 70 μm to a thickness of about 1mm, cured by 1000W medium-pressure mercury lamp for 15 seconds; test conditions: 100V DC bias voltage, 50°C, 90% RH, test time is 200 hours, no obvious The migration phenomenon of silver ions, see figure 2 .

Embodiment 2

[0041]

[0042] According to the preparation method of the above-mentioned ultraviolet light curing silver ion migration resistant plasma display circuit protective agent, an ultraviolet light curing silver ion migration resistant plasma display circuit protective agent is prepared. Coated on silver electrodes with a spacing of 70 μm to a thickness of about 1mm, cured by 1000W medium-pressure mercury lamp for 20 seconds; test conditions: DC bias voltage of 100V, 50°C, 90% RH, test time of 200 hours, no obvious migration of silver ions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com