Preparation method and application of hydrogenation deoxygenation catalyst for oxygen-containing organic compound

A deoxidation catalyst, organic compound technology, applied in physical/chemical process catalysts, organic chemistry, hydrogenolysis preparation, etc., can solve the problems of weak binding force between active metal and substrate surface, complicated production operation, easy crushing and pulverization, etc. The catalyst has the advantages of slow process conditions, good stability and selectivity, and strong process selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

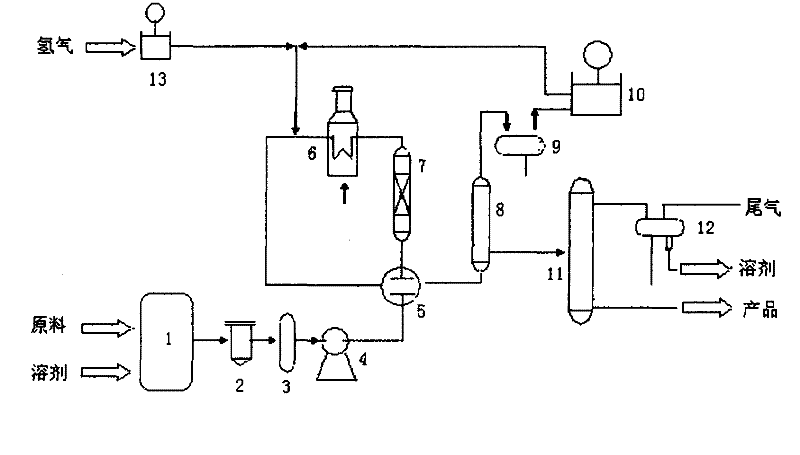

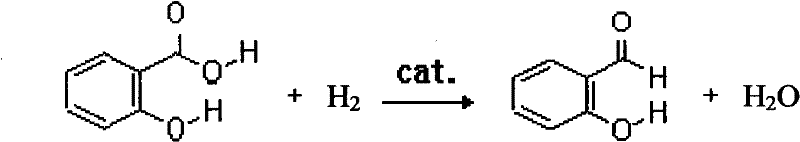

[0018] Two compositions of hydrodeoxygenation catalysts, labeled as sample A and sample B, were prepared for the reduction of salicylic acid, respectively. High purity salicylaldehyde is obtained.

[0019] The preparation process of sample A is as follows:

[0020] Step 1. Prepare mixed powder. Weigh 50kg of activated aluminum hydroxide powder with an average pore volume of 0.60mL / g, dry and dehydrate at 420°C for 8 hours, add the dehydrated powder to 1.5% of the mass ratio of scallop powder, and mix evenly in a dry powder mixer to obtain a mixed powder ;

[0021] Step 2. Preparation of catalyst blank carrier. Add 20% decationized water to the mixed powder obtained in step 1 according to the mass ratio, atomize the decationized water and mix with the mixed powder to obtain a wet material, roll the wet material into a ball to obtain a spherical carrier, and the diameter of the spherical catalyst carrier is 2 mm. The carrier was dried at 120°C for 8 hours, and after drying, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com