Method for extracting human fibrinogen from component I through column chromatography

A technology of human fibrinogen and column chromatography, which is applied to the preparation methods of fibrinogen and peptides, animal/human proteins, etc., can solve the problems of poor quality stability, low purity, and low yield, and achieve enhanced stability , to ensure stability and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

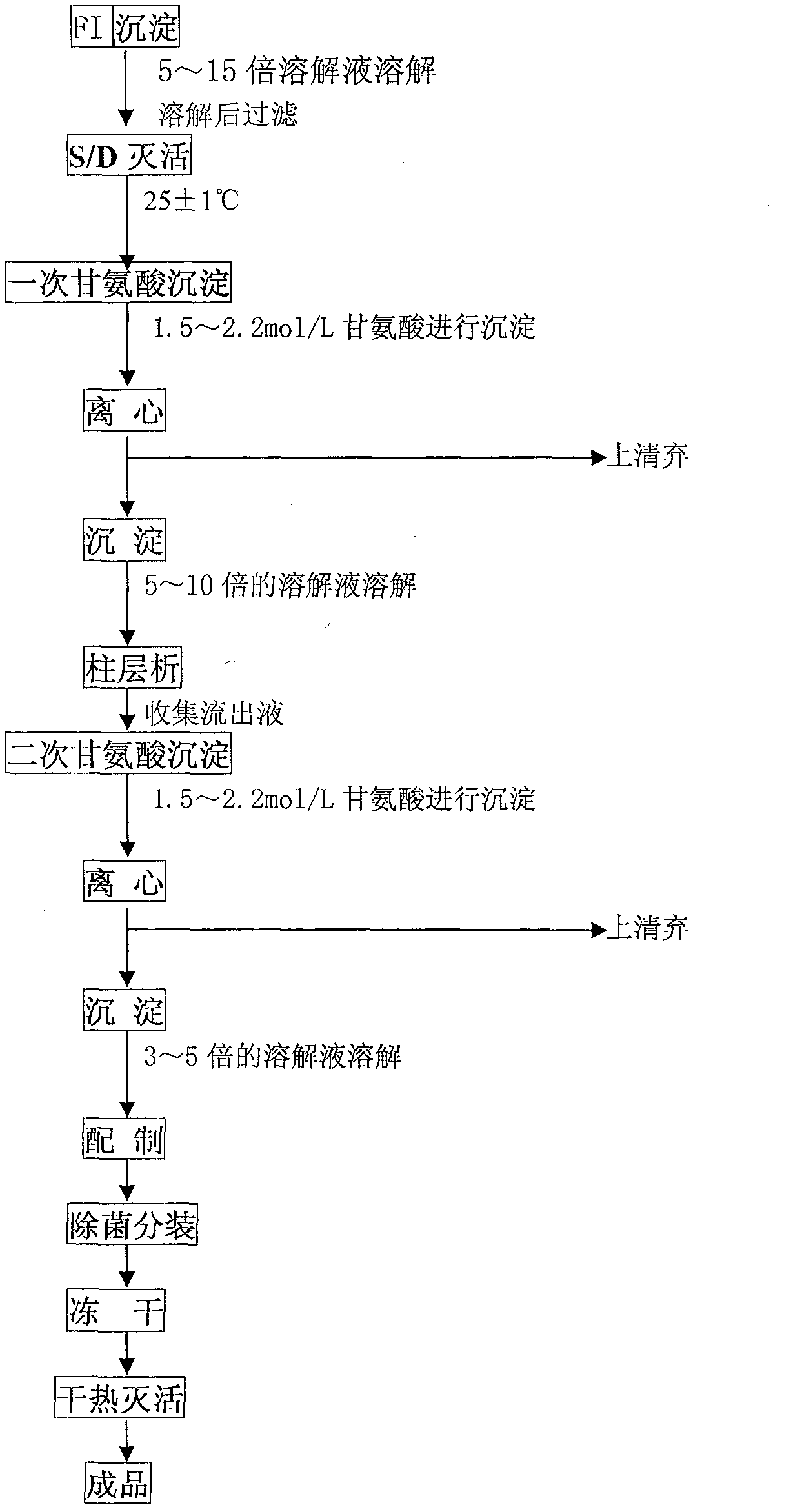

[0039] The present invention is realized by the following steps in concrete implementation:

[0040] (1) Dissolving and filtering of component I precipitation: use 5 times the volume of the first solution for the precipitation, stir and dissolve at 20°C for 1 hour, clarify and filter the dissolved product, and measure the volume of the product; the first solution is: Each 1000ml aqueous solution for injection contains: 10g trisodium citrate, 9g NaCl, 8g sucrose, 2g Tris, 3g lysine hydrochloride, adjust the pH value to 6.90 with HCl;

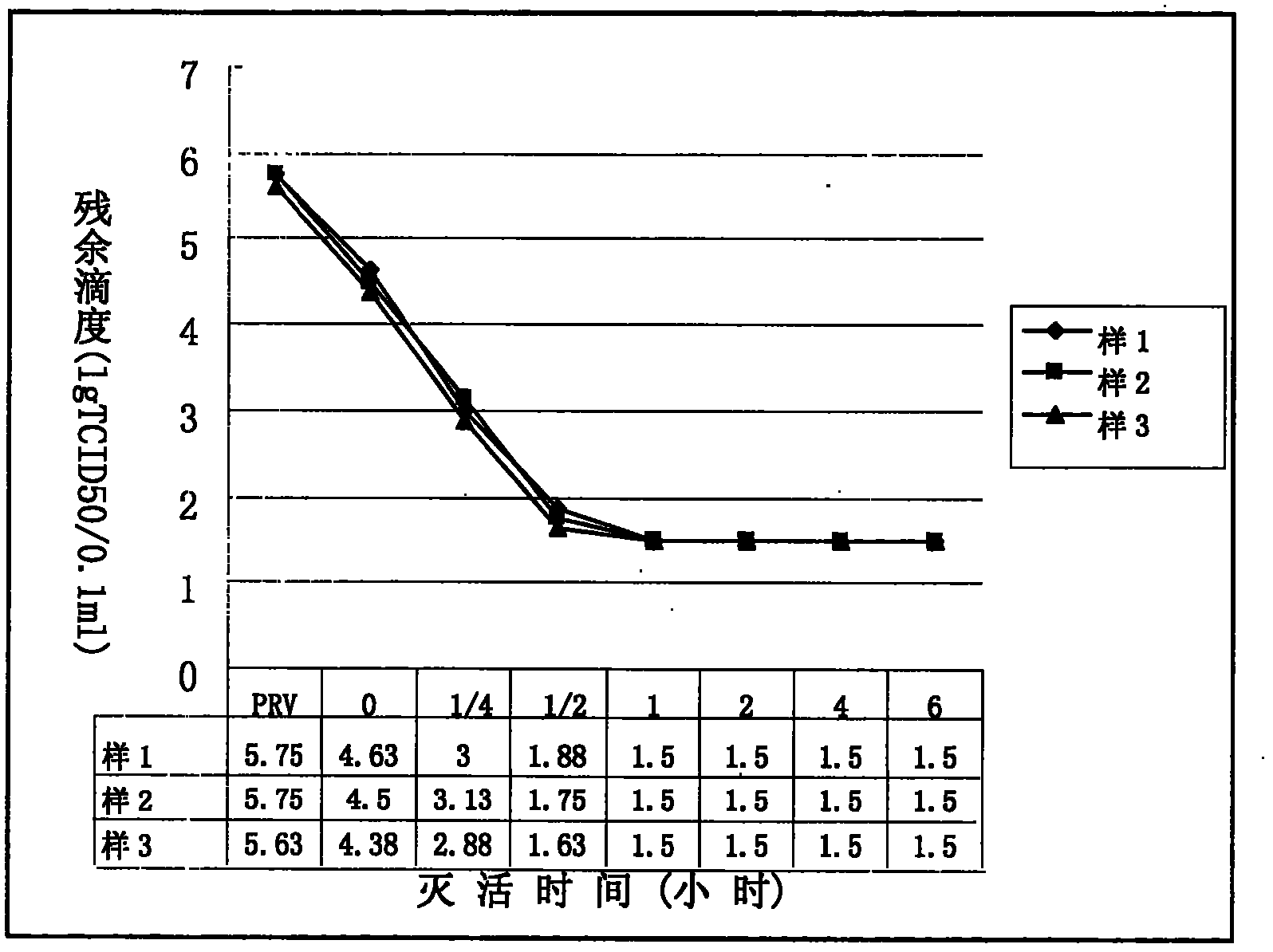

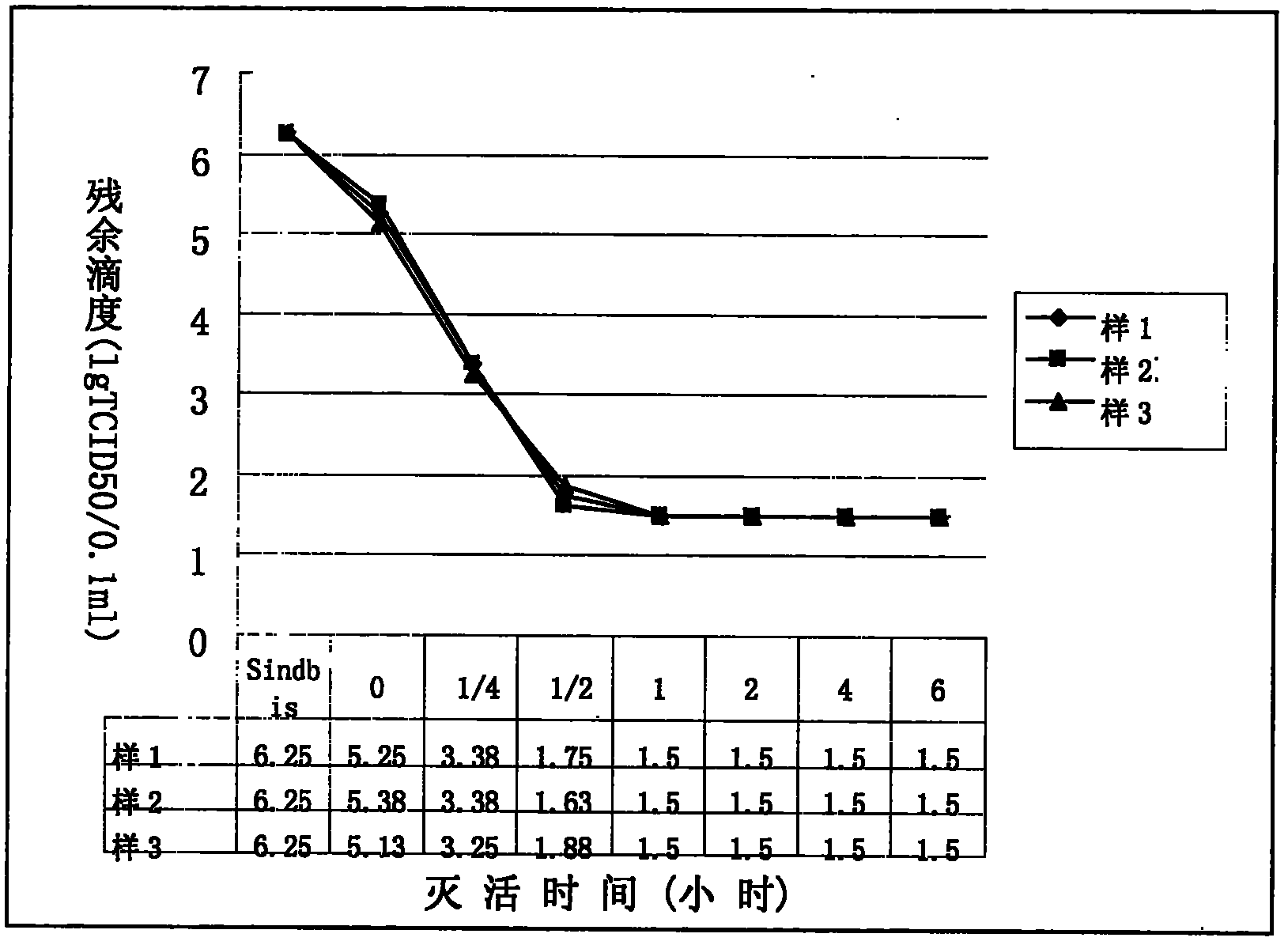

[0041](2) S / D inactivation: control the product temperature at 24°C, add 100ml per liter of filtrate, slowly add 11% S / D inactivator with a mass concentration under stirring, and keep the product temperature at 24°C6 Hour;

[0042] (3) The first glycine precipitation: measure the volume of the inactivation solution in step 2, add glycine powder at a concentration of 1.5mol / L, fully dissolve and cool to 2°C, perform continuous centrifugation at 4...

Embodiment 2

[0052] (1) Dissolving and filtering of component I precipitation: use 8 times the volume of the first solution for the precipitation, stir and dissolve at 23°C for 1 hour, clarify and filter the dissolved product, and measure the volume of the product; the first solution is: Each 1000ml aqueous solution for injection contains: 12g trisodium citrate, 9g NaCl, 10g sucrose, 3g Tris, 4g lysine hydrochloride, adjust the pH value to 7 with HCl;

[0053] (2) S / D inactivation: control the product temperature at 25°C, add 100ml per liter of filtrate, slowly add 11% S / D inactivator with a mass concentration under stirring, and keep the product temperature at 25°C6 Hour;

[0054] (3) The first glycine precipitation: measure the volume of inactivation solution in step 2, add glycine powder at a concentration of 1.8mol / L, fully dissolve and cool to 5°C, perform continuous centrifugation at 4200rpm for 40 minutes, and collect at 0°C precipitation;

[0055] (4) Dissolution and filtration o...

Embodiment 3

[0064] (1) Dissolving and filtering of component I precipitation: use 15 times the volume of the first solution for the precipitation, stir and dissolve at 26°C for 1 hour, clarify and filter the dissolved product, and measure the volume of the product; the first solution is: Each 1000ml aqueous solution for injection contains: 14g trisodium citrate, 9g NaCl, 12g sucrose, 4g Tris, 5g lysine hydrochloride, adjust the pH value to 7.10 with HCl;

[0065] (2) S / D inactivation: control the product temperature at 26°C, add 100ml per liter of filtrate, slowly add 11% S / D inactivator with a mass concentration under stirring, and keep the product temperature at 26°C6 Hour;

[0066] (3) The first glycine precipitation: measure the volume of inactivation solution in step 2, add glycine powder at a concentration of 2.2mol / L, fully dissolve and cool to 8°C, perform continuous centrifugation at 4200rpm for 40 minutes, and collect at 0°C precipitation;

[0067] (4) Dissolution and filtrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com