Compound probiotics preparation for biological organic fertilizers and preparation method thereof

A technology of compound probiotics and bio-organic fertilizers, which is applied in urban greening, environmental protection, and agricultural applications, can solve the problem that the microbial flora of soil flora cannot be supplemented, the effective number of viable bacteria of bio-organic fertilizers cannot be reached, and the products do not meet the requirements. Bio-organic fertilizers and other issues, to achieve the effect of being suitable for large-scale production and application, improving crop yield and disease resistance, and improving poor soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

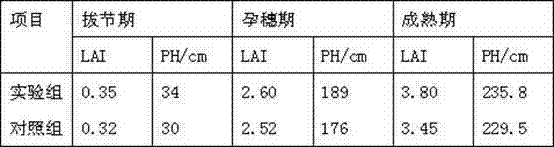

Examples

Embodiment 1

[0034]Use the mixed inoculation method to activate the good strains, according to Pseudomonas: Streptomyces mutatis mutans: Rhizobium: Brown spherical nitrogen-fixing bacteria: Bacillus subtilis: Bacillus amyloliquefaciens: Bacillus cereus: Bacillus licheniformis: Webster Bacillus: jelly-like Bacillus: Bacillus thuringiensis: Saccharomyces luteus: Streptomyces griseus rust var: Streptomyces luteus=1:1:1:1:1:1:1:1:1:1:1: The ratio of 1:1:1 was mixed and inoculated into 500mL liquid seed medium, cultured on a shaker at 28°C with a speed of 200 rpm, and fermented for 2 days. Then transferred to the 5L secondary seed shake flask, cultured on a shaker at 28°C with a rotation speed of 200 rpm, and fermented for 2 days. Transfer to 50L seed tank again, temperature 28 ℃, rotating speed 200 rpm, ferment for 2 days. The strains in the seed tank were transported to a 500L fermenter at a temperature of 28°C and a rotation speed of 200 rpm, and fermented for 3 days to obtain a liquid comp...

Embodiment 2

[0041] Change the fermentation time and temperature in embodiment 1, namely the fermentation temperature of first-level liquid seed, second-level liquid seed, seed tank and expanded cultivation has 28 ℃ to change to 30 ℃, and the fermentation time has 2 days to prolong to 3 days, simultaneously Molasses concentration increased from 3% to 5%. The obtained liquid composite probiotic agent was mixed evenly with 5 tons of weathered coal, and the stacking time was extended from 3 days to 5 days. Under this condition, solid powder is made, and the effective number of viable bacteria of the solid composite probiotic is 3.8 billion / gram.

[0042] Liquid seed medium formula is identical with embodiment 1.

[0043] The composition and mass content of the 500L fermentation tank culture medium are: molasses 5%, that is 25000g; beef extract 0.3%, that is 1500g; peptone 1%, that is 5000g; sodium chloride 0.5%, that is 2500g; magnesium sulfate 0.05%, that is 250g; Potassium dihydrogen phos...

Embodiment 3

[0045] Change the pH6.8 of the fermentation medium in Example 1 to pH7.4, and the fermentation temperature and fermentation time are the same as in Example 2. That is, in terms of Pseudomonas: Streptomyces violaceum: Rhizobium: Azotobacter sphaeroides: Bacillus subtilis: Bacillus amyloliquefaciens: Bacillus cereus: Bacillus licheniformis: Bacillus weideri: Bacillus jelly-like: Bacillus thuringiensis: Saccharomyces luteus: Streptomyces griseus rust variant: Streptomyces luteus = 1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1 ratio inoculation, The fermentation temperature of the first-grade liquid seeds, second-grade liquid seeds, seed tanks and expanded cultivation is 30°C, the fermentation time is 3 days, the pH value is 7.4, the concentration of molasses is 3%, and the stacking time is 5 days. Under this condition, solid powder is made, and the effective number of viable bacteria of this solid composite probiotic is 3.5 billion / gram.

[0046] Liquid seed medium formula is identical with e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com