Method for treating low-grade zinc oxide ore by using weakly alkaline amino acid salt system

A technology of amino acid salt and zinc oxide ore, applied in the direction of improving process efficiency, etc., can solve problems such as difficult filtration, difficult return of zinc-containing leaching solution, and high side effects of ammonia gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

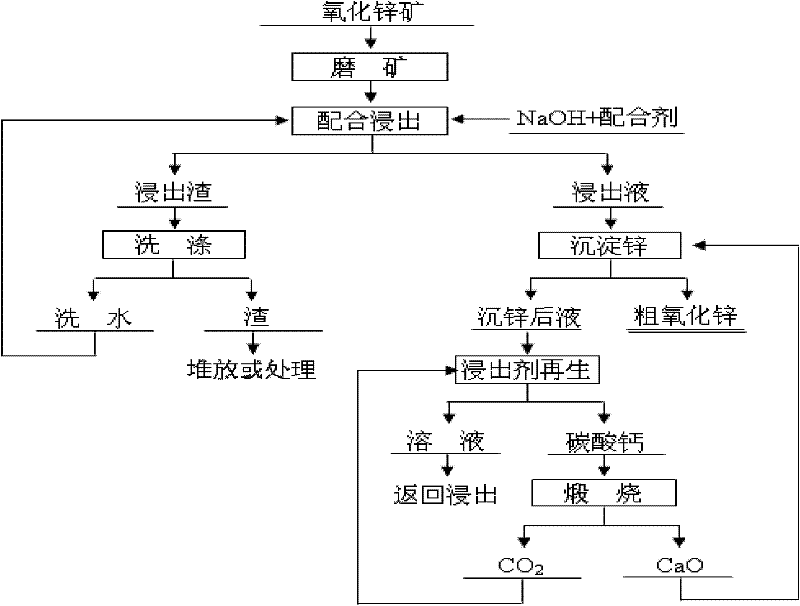

[0031] see figure 1 , after the zinc oxide ore is ground, the obtained ore powder passes through a sieve with a pore size of 150um, and its main components (wt%): Zn 6.5, Fe 6.5, CaO 25.74, MgO 0.83, Al 2 o 3 2.20, SiO 2 17.53, Cu 0.0049, Pb 0.91 and S 4.60, of which the zinc content in sphalerite is 0.97%, and the rest is oxidized zinc; technical grade sodium glutamate, content ≥ 95%; industrial sodium hydroxide, content ≥ 96% %; industrial grade calcium oxide, content ≥ 88%, ground finely through a 106um sieve.

[0032] Mix 133.5 g of the above-mentioned sodium glutamate with 500 ml of water, adjust its pH value to 9 with NaOH at 80° C. to obtain a leaching solution with a total concentration of ligand glutamate of 1.5 mol / L, and adjust the stirring speed to 300 r / min. Add 100g of zinc oxide ore, stir and leaching for 5 hours, filter while hot, wash the leaching residue with water and store it, combine the washing water and leaching solution to obtain 550ml of leaching ...

Embodiment 2

[0036] see figure 1 , after the zinc oxide ore is ground, the aperture is 150um, and its main components (wt%): Zn 7.72, Fe 4.84, CaO 8.02, MgO 0.57, Cd 0.23, SiO 2 46.06, Cu 0.01, Ni 0.0019, Pb 1.86, among which the zinc content in sphalerite is 1.35%, and the rest is oxidized zinc. Industrial grade iminodiacetic acid, content ≥ 95%; industrial sodium hydroxide, content ≥ 96%; industrial grade calcium oxide, content ≥ 88%, finely ground through a 106um sieve.

[0037] Mix 140g of the above-mentioned iminodiacid with 1000ml of water, adjust its pH value to 8 with NaOH at 70°C to obtain a leaching solution with a total concentration of ligand iminodiacetate radicals of 1mol / L, and adjust the stirring speed to 300r / min , add 200g of zinc oxide ore, filter while hot after leaching for 4 hours, wash the leached slag with water and stockpile, combine the washing water and leaching solution to obtain 1000ml of leaching solution, leaching solution composition (mg / L): Zn 11844, Ca 5...

Embodiment 3

[0042] see figure 1 , after the zinc oxide ore is ground, the aperture is 150um, and its main components (wt%): Zn 7.72, Fe 4.84, CaO 8.02, MgO 0.57, Cd 0.23, SiO2 46.06, Cu 0.01, Ni 0.0019, Pb 1.86, of which The zinc content in sphalerite is 1.35%, and the rest is oxidized zinc. Industrial grade aminoacetic acid, content ≥ 98%; industrial sodium hydroxide, content ≥ 96%; industrial grade calcium oxide, content ≥ 88%, finely ground through a 150um sieve.

[0043] Mix 92g of the above-mentioned aminoacetic acid with 1000ml of water, and adjust its pH value to 8.5 with NaOH at 75°C to obtain a leaching solution with a total concentration of ligand aminoacetic acid radicals of 1.2mol / L, adjust the stirring speed to 300r / min, add oxidation Zinc ore 200g, leached for 6 hours and then filtered while hot, the leached slag was washed with water and then stockpiled, the washing water and the leaching solution were combined to obtain 1000ml of leaching solution, the composition of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com