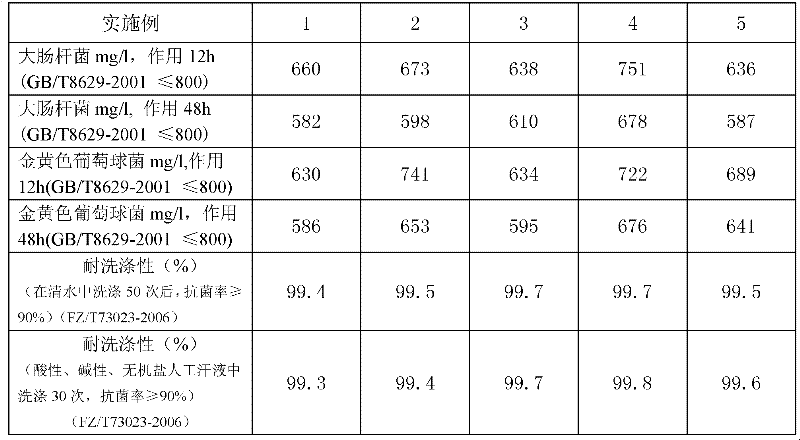

Microcapsule nano silver antibacterial fabric and preparation method thereof

A nano-silver antibacterial and microcapsule technology, applied in the field of antibacterial fabrics, can solve the problems of poor washing resistance, low temperature resistance, and easy discoloration of antibacterial fabrics, achieve excellent antibacterial performance and high temperature resistance, and enhance washing resistance and durability The effect of enhancing biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

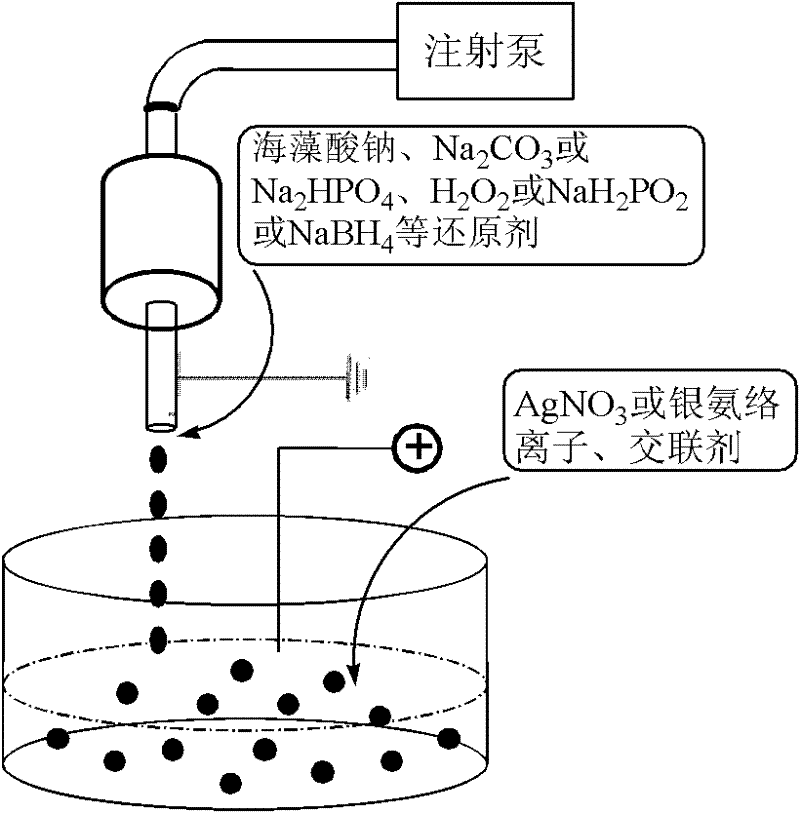

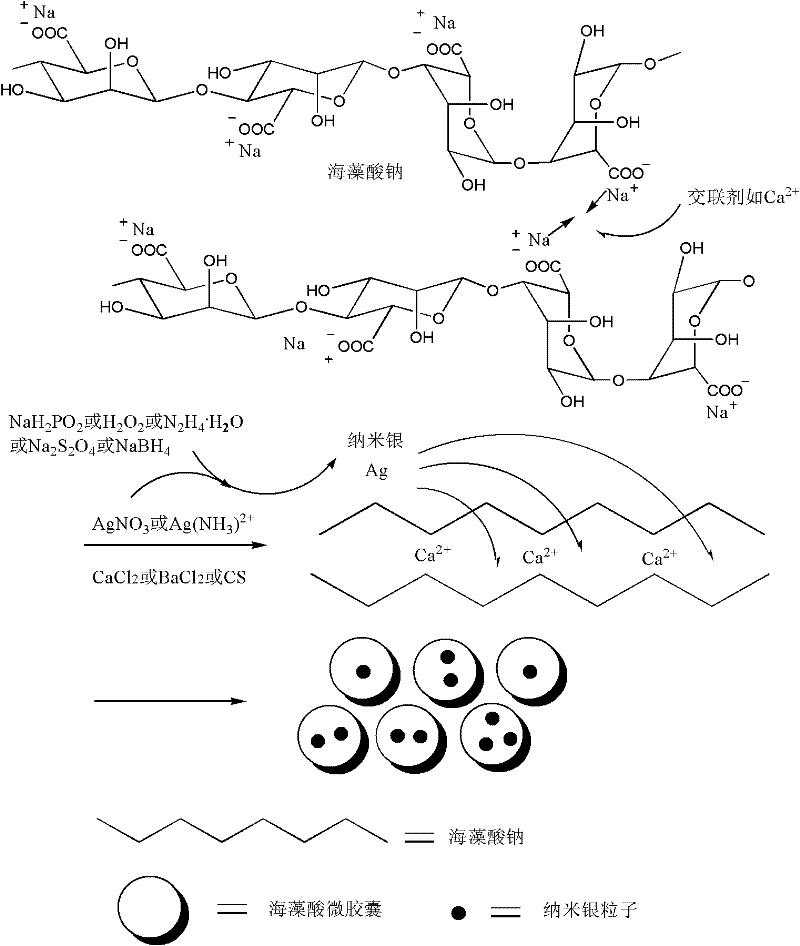

[0026] Step 1, 1g sodium alginate (weight average molecular weight M W =2*10 5 gmol -1 ) was dissolved in 20g of distilled water to prepare a 0.5% by mass sodium alginate aqueous solution, and then add 1g of Na 2 CO 3 , adjust the pH to 7;

[0027] Step 2, mixing 0.2g of 5% by mass sodium hypophosphite aqueous solution, 2.5g of sodium polyacrylate and 5g of 0.5% by mass sodium alginate aqueous solution to obtain a mixed solution A;

[0028] Step 3, 13.7g of 2% CaCl 2 The aqueous solution and 3.39g of 0.05% silver nitrate solution were mixed uniformly to obtain solution B;

[0029] Step 4, take by weighing 7.7g of solution A, join in electrostatic bead generator (see figure 1 , voltage 7KV, flow rate 8ml / h), after stirring evenly at a speed of 200rpm, the mixed solution was added dropwise to 17.09g solution B, and after standing for 1h, the obtained microspheres were rinsed 3 times with distilled water, separated by filtration , and finally absorb the surface moisture wi...

Embodiment 2

[0032] Step 1, 1.5g sodium alginate (weight average molecular weight M W =3*10 5 gmol -1 ) is dissolved in 75g NaCl solution, is prepared into the NaCl solution of the sodium alginate of 2% mass percent, then adds 1.8g NaHPO 4 , adjust the pH to 7.2;

[0033] Step 2, mixing 1.67g of 0.68% by mass hydrogen peroxide solution, 5g of sodium dodecylsulfonate and 24g of 2% by mass aqueous solution of sodium alginate to obtain mixed solution A;

[0034] Step 3, 20.18g of 3% CaCl 2 solution and 6.45g of 0.85% Ag(NH 3 ) 2 + The solution is mixed evenly to obtain solution B;

[0035] Step 4, take by weighing 30.67g of solution A, join in electrostatic bead generator (see figure 1 , voltage 7KV, flow rate 8ml / h), after stirring evenly at a speed of 250rpm, the mixed solution was added dropwise to 26.63g solution B, and after standing for 3h, the obtained microspheres were rinsed 3 times with distilled water, separated by filtration , and finally absorb the surface moisture with ...

Embodiment 3

[0038] Step 1, 3g sodium alginate (weight average molecular weight M W =3*10 5 gmol -1 ) was dissolved in 85.7g NaCl solution, prepared into 3.5% by mass percent sodium alginate aqueous solution, then added 3.8g NaCl 2 CO 3 , adjust the pH to 7.2;

[0039] Step 2, mixing 2.53g of 20% by mass hydrazine hydrate solution, 6.34g of fatty acid polyoxyethylene ether and 38g of 3.5% by mass of sodium alginate aqueous solution to obtain mixed solution A;

[0040] Step 3, the 3.5% chitosan acetic acid solution of 42.0g and the 0.92% Ag(NH 3 ) 2 + The solution is mixed evenly to obtain solution B;

[0041] Step 4, take by weighing 46.87g of solution A, join in electrostatic bead generator (see figure 1 , voltage 7KV, flow rate 8ml / h), after stirring evenly at a speed of 300rpm, the mixed solution was added dropwise to 50.64g solution B, and after standing for 4h, the obtained microspheres were rinsed 3 times with distilled water, separated by filtration , and finally absorb the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com