Light-emitting diode with transparent electrode and preparation method

A technology of light emitting diodes and transparent electrodes, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of increasing thin film resistance, reducing light transmittance, and large operating voltage, reducing contact resistivity and improving light transmittance. efficiency, prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

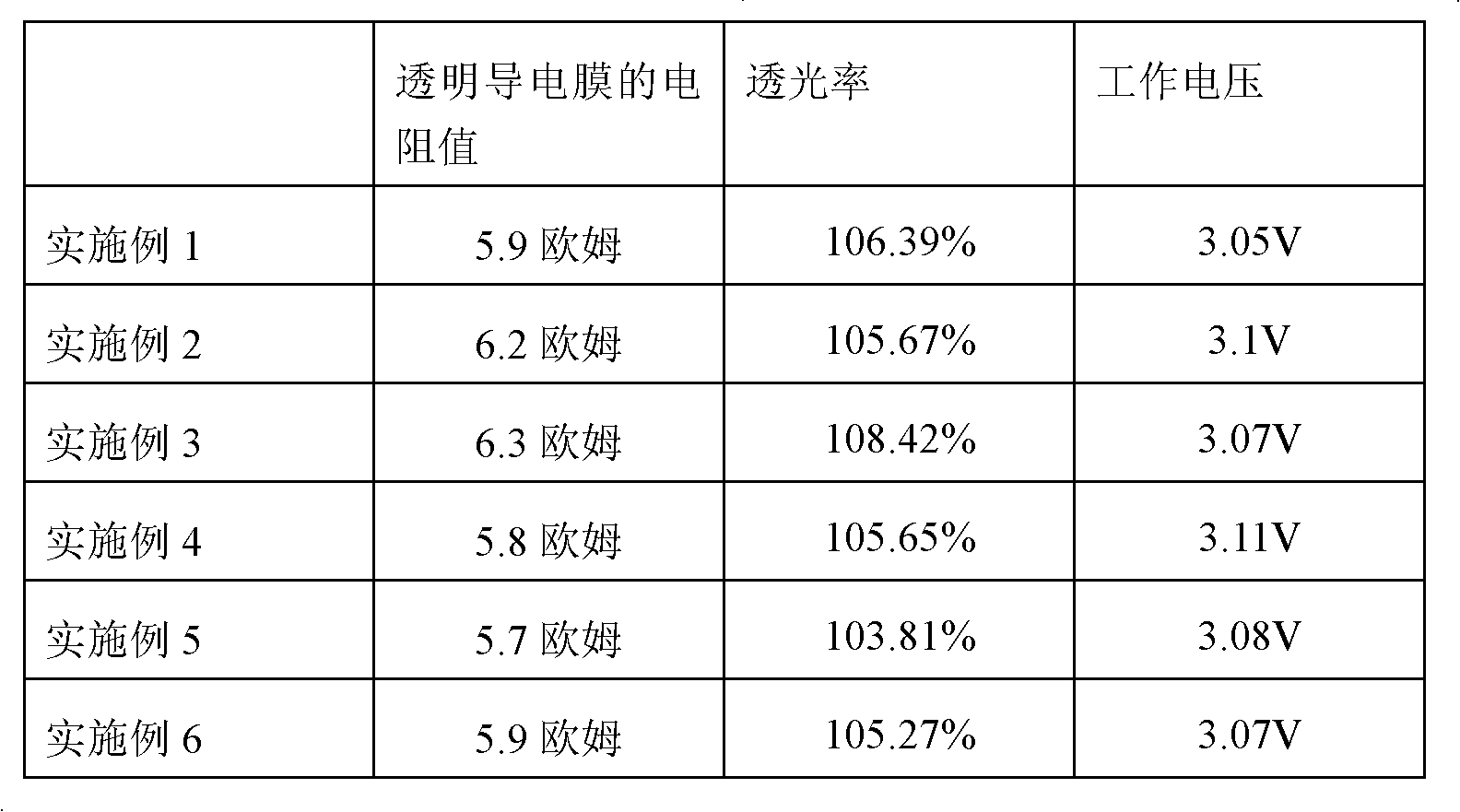

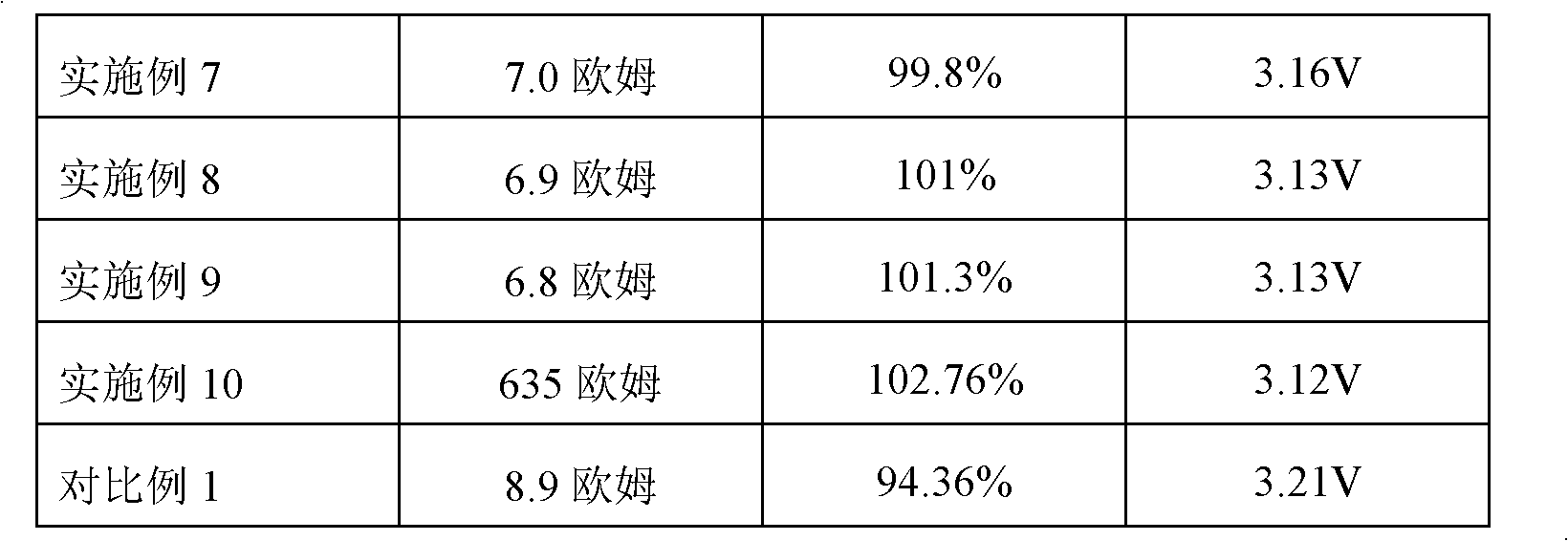

Examples

preparation example Construction

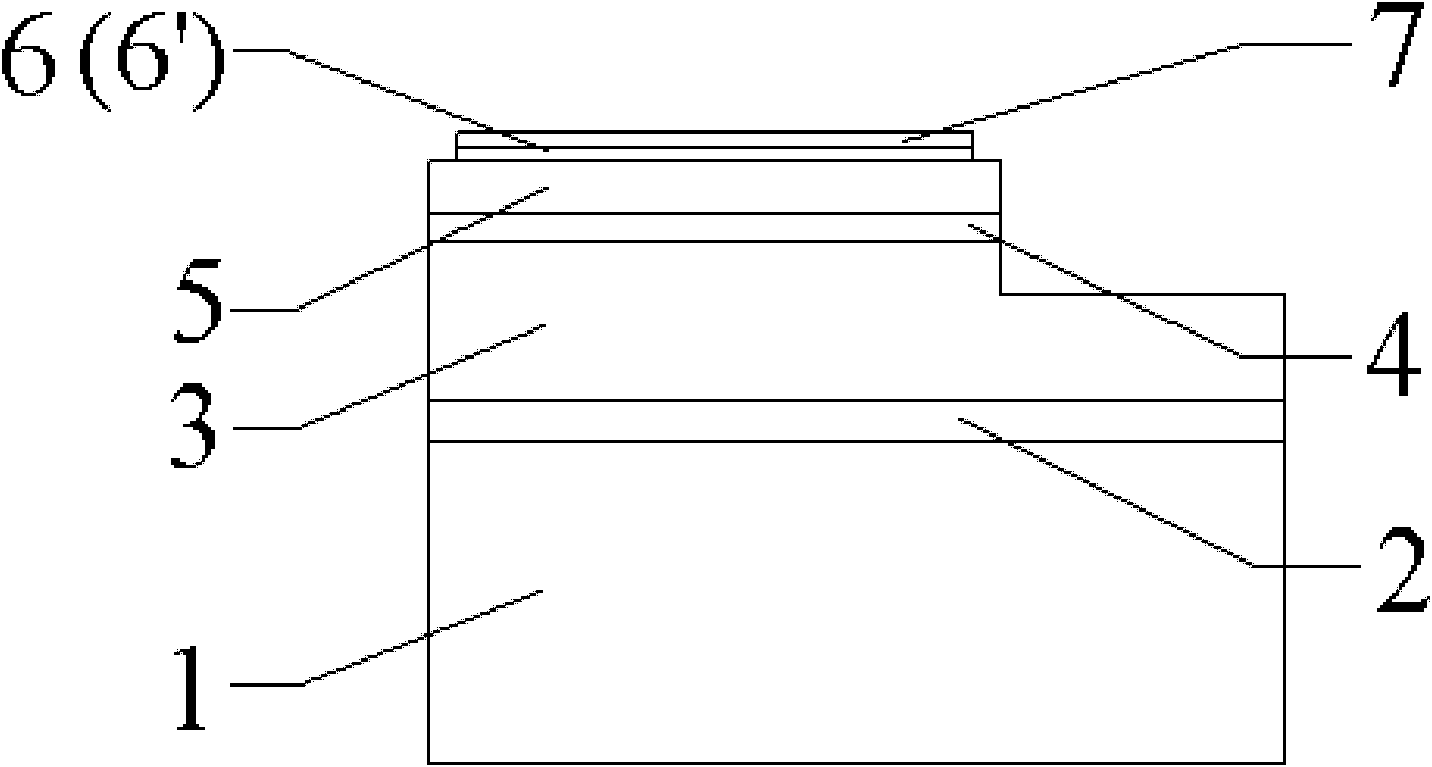

[0034] At the same time, in a typical embodiment of the present invention, a method for preparing a transparent electrode light-emitting diode is also provided, which includes a method for preparing a gallium nitride epitaxial wafer, and the method for preparing a gallium nitride epitaxial wafer includes the following steps: Growing a P-type gallium nitride layer 5; preparing a titanium layer 6 or a titanium oxide layer 6' on the P-type gallium nitride layer 5; preparing a zinc oxide layer 7 on the titanium layer 6 or the titanium oxide layer 6' to form a titanium / oxide layer Zinc or titanium oxide / zinc oxide composite transparent conductive film.

[0035] A specific preparation method for preparing a titanium / zinc oxide composite transparent conductive film and a titanium oxide / zinc oxide composite transparent conductive film is respectively given as follows.

[0036] Wherein, in the step of preparing the titanium / zinc oxide composite transparent conductive film, the step of ...

Embodiment 1

[0044] The specific operation steps are as follows:

[0045] 1. High temperature treatment: In the MOCVD reaction chamber, high-purity H 2 , reduce the pressure of the reaction chamber to 150mbar, heat the 0001-face sapphire 1 to 1100°C, and treat at high temperature for 5 minutes to 20 minutes.

[0046] 2. Nitriding treatment: reduce the temperature to 500°C, and use NH with a flow rate of 8 standard liters / minute 3 It is passed into the reaction chamber and maintained for 120 seconds to perform nitriding treatment on the sapphire substrate 1 .

[0047] 3. Growth of low-temperature buffer gallium nitride layer 2: reduce the temperature to 500°C, increase the pressure to 600mbar, and 2 Under the atmosphere, NH with a flow rate of 8 standard liters / min 3 , the flow rate is 3.8×10 -4 TMGa per mol / min, H2 at a flow rate of 80 standard liters / min, and a low-temperature buffer gallium nitride layer 2 with a thickness of 30 nanometers grown on a sapphire substrate.

[0048] 4. ...

Embodiment 2

[0055] Preparation method: steps 1-6 are the same as in Example 1, and step 7 is as follows:

[0056] Preparation of titanium / zinc oxide composite transparent conductive film: at room temperature, greater than 10 -7 Under the vacuum degree of Torr, the titanium layer 6 of 25 angstroms is formed by vacuum evaporation using an electron beam evaporation machine; after the titanium layer 6 is formed, the temperature is raised to 500 ° C, and the heat treatment is carried out in an atmosphere with a volume ratio of nitrogen and oxygen of 10:40. The titanium layer 6 forms a surface protection layer; in the environment where the volume ratio of 38% hydrochloric acid and 65% nitric acid is 3:1, the wet etching titanium layer 6 forms a first through hole with a diameter of 1.5 microns; The temperature is adjusted to 200°C, and the oxygen flow rate is 8 sccm, greater than 10 -6 Under the vacuum degree of Torr, use an oxide evaporation machine to vacuum vapor-deposit to form a 3000 angs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com