A kind of sustained-release microsphere preparation of osteocalcin for injection

A slow-release microsphere preparation and osteocalcin technology, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, bone diseases, etc., can solve the problems of easy degradation, difficult purification of extracts, poor stability, etc. problem, to achieve the effect of easy control of process conditions, good safety in vivo, and convenient quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

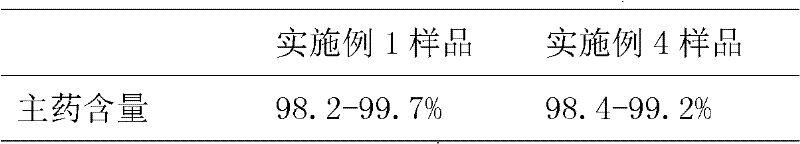

Embodiment 1

[0020] Example 1 Preparation of sustained-release microspheres for injection of osteocalcin

[0021] The formula is as follows:

[0022] Osteocalcin 20g

[0024] Lactic acid-glycolic acid copolymer 100g.

[0025] The preparation method is as follows:

[0026] 1) dissolving osteocalcin and zinc sulfate in water, adjusting the pH value to 8-10 with sodium bicarbonate, as the inner water phase;

[0027] 2) dissolving the lactic acid-glycolic acid copolymer in methylene chloride as the oil phase;

[0028] 3) Mix the inner water phase with the oil phase, and stir at 9500 rpm under ice bath conditions to form colostrum;

[0029] 4) under the stirring condition of 9500 rpm, adding colostrum into polyvinyl alcohol aqueous solution with a mass concentration of 4% to obtain double emulsion;

[0030] 5) Stir the double emulsion at room temperature at 9500 rpm for 5 hours, collect the microspheres by centrifugation, wash the microspheres with water for i...

Embodiment 2

[0031] Example 2 Preparation of sustained-release microspheres for injection of osteocalcin

[0032] The formula is as follows:

[0033] Osteocalcin 30g

[0035] Lactic acid-glycolic acid copolymer 100g.

[0036] The preparation method is as follows:

[0037] 1) dissolving osteocalcin and zinc sulfate in water, adjusting the pH value to 8-10 with sodium bicarbonate, as the inner water phase;

[0038] 2) dissolving the lactic acid-glycolic acid copolymer in methylene chloride as the oil phase;

[0039] 3) Mix the inner water phase with the oil phase, and stir at 9500 rpm under ice bath conditions to form colostrum;

[0040] 4) under the stirring condition of 9500 rpm, adding colostrum into polyvinyl alcohol aqueous solution with a mass concentration of 4% to obtain double emulsion;

[0041] 5) Stir the double emulsion at room temperature at 9500 rpm for 5 hours, collect the microspheres by centrifugation, wash the microspheres with water for i...

Embodiment 3

[0042] Embodiment 3 prepares the sustained-release microsphere preparation for injection of osteocalcin

[0043] The formula is as follows:

[0044] Osteocalcin 15g

[0046] Lactic acid-glycolic acid copolymer 100g.

[0047] The preparation method is as follows:

[0048] 1) dissolving osteocalcin and zinc sulfate in water, adjusting the pH value to 8-10 with sodium bicarbonate, as the inner water phase;

[0049] 2) dissolving the lactic acid-glycolic acid copolymer in methylene chloride as the oil phase;

[0050] 3) Mix the inner water phase with the oil phase, and stir at 9500 rpm under ice bath conditions to form colostrum;

[0051] 4) under the stirring condition of 9500 rpm, adding colostrum into polyvinyl alcohol aqueous solution with a mass concentration of 4% to obtain double emulsion;

[0052] 5) Stir the double emulsion at room temperature at 9500 rpm for 5 hours, collect the microspheres by centrifugation, wash the microspheres with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com