Organic-inorganic block controlled release fertilizer and preparation method thereof

A technology of controlled-release fertilizers and organic materials, applied in the field of agricultural chemistry, can solve problems such as the lack of combination of organic fertilizers, difficulty in large-scale application by ordinary farmers, and easy damage to the properties of organic materials, so as to reduce nutrient loss and save labor costs , Improve the effect of fertilizer utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

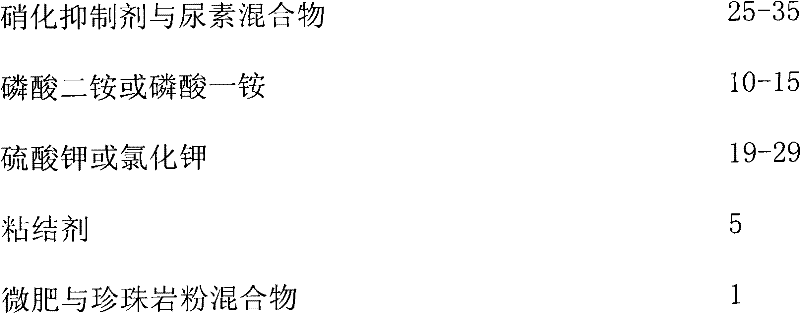

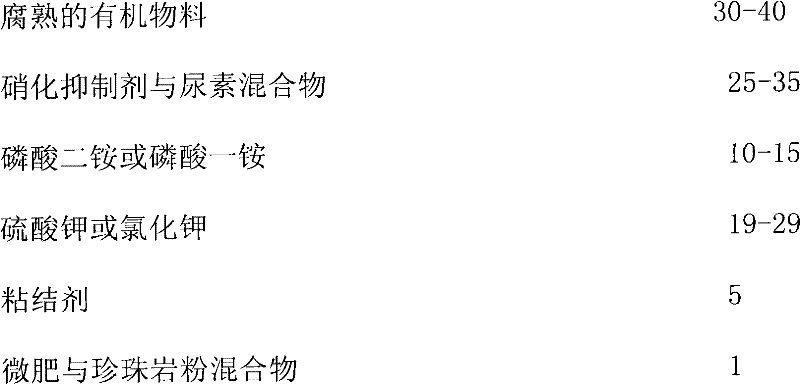

Embodiment 1

[0035] Mix peat, biogas residues, bamboo residues, livestock and poultry manure, straw, coconut bran, and waste edible fungus cultivation base materials, build and chop them up, dry them naturally to reduce the moisture to 40%-50% (W / W), and then pile them up Set to rot. Crush the decomposed organic material with a pulverizer, pass through a fine sieve with an aperture of 5mm, then dry or expose to the sun to reduce the water content to 15%-25% (W / W), and set aside

[0036] Get decomposed organic material 400kg, dicyandiamide and urea mixture 250kg (the weight content of dicyandiamide is urea weight 10%), diammonium phosphate 100kg, potassium sulfate 190kg, diatomite and bentonite mixture 50kg, micronutrient fertilizer and perlite Powder mixture 10kg. Wherein the micro-fertilizer is copper sulfate, magnesium sulfate, zinc sulfate, ferrous sulfate, boric acid, manganese sulfate, and its weight ratio with perlite is 1:1:1:1:1:1:94.

[0037] Mix the components evenly, put the m...

Embodiment 2

[0040] Mix straw, coir peat, waste edible fungus cultivation base material and distiller's grains, build and chop to make a high pile, air dry naturally to reduce the water content to 40%-50% (W / W), and then pile and decompose. Crush the decomposed organic material with a pulverizer, pass through a fine sieve with an aperture of 5mm, then dry or expose to the sun to reduce the water content to 15%-25% (W / W), and set aside

[0041] Get decomposed organic material 350kg, dicyandiamide and urea mixture 250kg (the weight content of dicyandiamide is 5% of urea weight), monoammonium phosphate 150kg, potassium chloride 190kg, bentonite 50kg, micronutrient fertilizer and perlite powder mixture 10kg . Wherein the micro-fertilizer is copper sulfate, magnesium sulfate, zinc sulfate, ferrous sulfate, boric acid, and its weight ratio with perlite is 1:1:1:1:1:95.

[0042]The components are uniformly mixed, and the weight of each part is 30 g, and the material is added into a cylindrical m...

Embodiment 3

[0045] Mix waste edible mushroom cultivation base materials, distiller's grains, furfural residues, tea residues, rice bran, and sawdust, pile them up high, dry them naturally to reduce the moisture to 40%-50% (W / W), and then pile them up for maturity. Crush the decomposed organic material with a pulverizer, pass through a fine sieve with an aperture of 5mm, then dry or expose to the sun to reduce the water content to 15%-25% (W / W), and set aside

[0046] Get decomposed organic material 300kg, 3,4-dimethylpyrazole phosphate and urea mixture 250kg (3, the weight content of 4-dimethylpyrazole phosphate is 0.5% of urea weight), monoammonium phosphate 100kg, Potassium chloride 190kg, bentonite 50kg, micro fertilizer and perlite powder mixture 10kg. Wherein the micro-fertilizer is magnesium sulfate, zinc sulfate, ferrous sulfate, boric acid, and its weight ratio with perlite is 1:1:1:1:96.

[0047] Mix the components evenly, put the material into a cylindrical mold of a hydraulic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com