Solution for preparing self-hole-sealing ceramic coating with high corrosion resistance on magnesium alloy surface and application thereof

A ceramic coating, magnesium alloy technology, applied in anodizing and other directions, can solve problems such as high peak current density, achieve uniform thickness, improved corrosion resistance, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this example, the composition of the high corrosion resistance self-sealing ceramic coating solution prepared by micro-arc oxidation on the surface of magnesium alloy under constant current / constant pressure mode is as follows:

[0033] 10 g / L potassium fluozirconate, 12 g / L ammonium dihydrogen phosphate, 15 g / L potassium fluoride, 6 g / L sodium citrate, 70 g / L hexamethylenetetramine and the rest of water; sample For AM60 die-cast magnesium alloy. The micro-arc oxidation power supply adopts a constant current / constant voltage pulse power supply with a frequency of 500Hz and a duty cycle of 50%. The method for preparing the ceramic coating is:

[0034] 1) Mechanical pretreatment and degreasing treatment;

[0035] Among the present invention, described mechanical pretreatment refers to that sample is ground with sandblasting or sandpaper, removes burr, surface oxide etc.; 1. Wash with 15 g / L sodium carbonate compound aqueous solution to remove general dirt, sintered ...

Embodiment 2

[0042] In this example, the composition of the high corrosion resistance self-sealing ceramic coating solution prepared by micro-arc oxidation on the surface of magnesium alloy under constant current / constant pressure mode is as follows:

[0043] 8 g / L sodium fluozirconate, 10 g / L sodium dihydrogen phosphate, 20 g / L ammonium fluoride, 4 g / L potassium citrate, 80 g / L hexamethylenetetramine and the balance water; sample Extruded magnesium alloy for AZ31. The micro-arc oxidation power supply adopts a constant current / constant voltage pulse power supply with a frequency of 300Hz and a duty cycle of 40%.

[0044] Its preparation method is identical with embodiment 1.

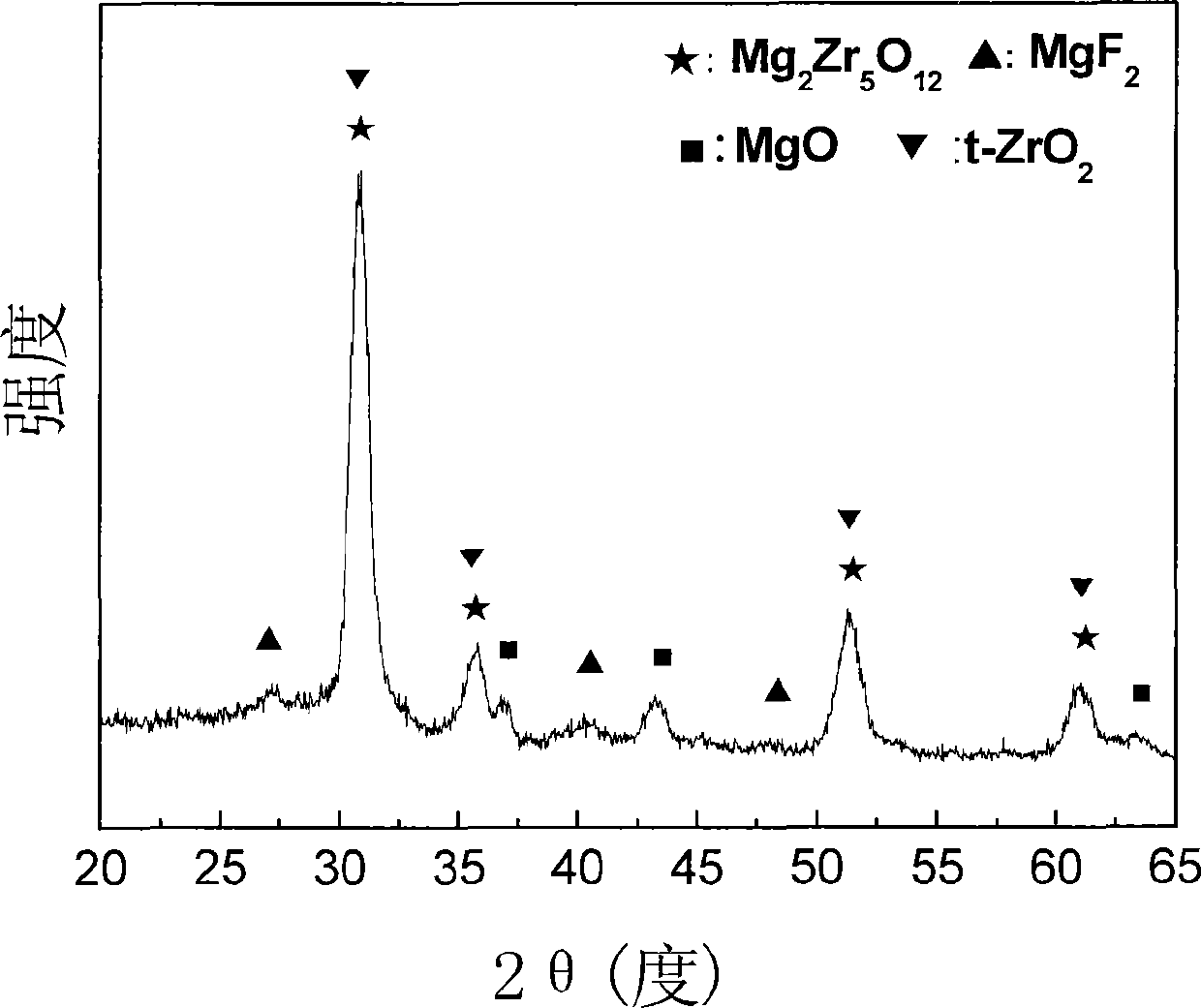

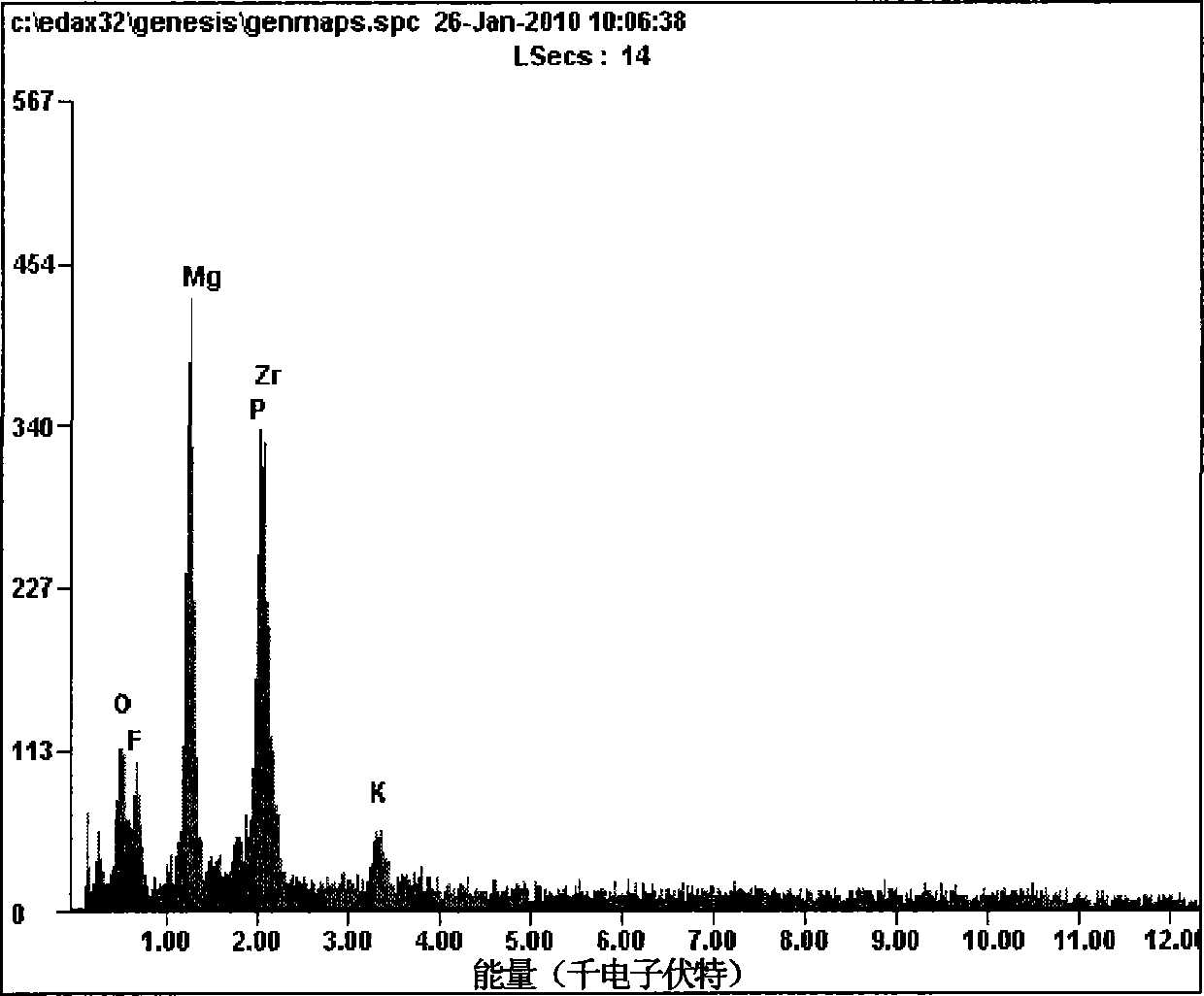

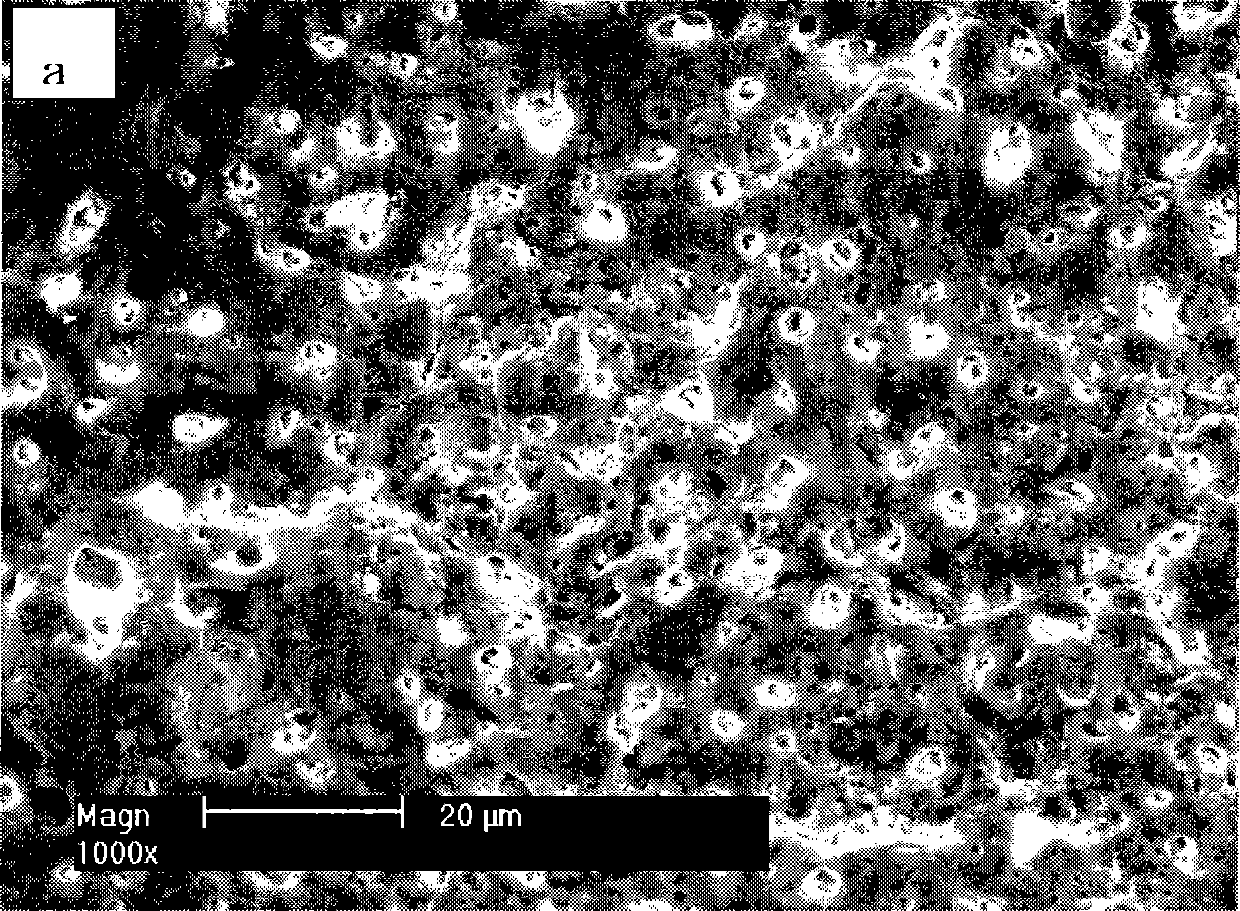

[0045] In this example, the thickness of the ceramic coating is 20 μm, and the element composition of the coating is as follows: Zr, Mg, O, F, P, and the phase structure mainly includes Mg 2 Zr 5 o 12 , t-ZrO 2 , MgF 2 , MgO.

[0046] In this embodiment, the performance parameters of the ceramic coating are as...

Embodiment 3

[0048] In this example, the composition of the high corrosion resistance self-sealing ceramic coating solution prepared by micro-arc oxidation on the surface of magnesium alloy under constant current / constant pressure mode is as follows:

[0049] 10 g / L sodium fluozirconate, 8 g / L potassium dihydrogen phosphate, 15 g / L sodium fluoride, 8 g / L potassium sodium citrate, 70 g / L hexamethylenetetramine and the rest of water; The sample is AM50 die-cast magnesium alloy. The micro-arc oxidation power supply adopts a constant current / constant voltage pulse power supply with a frequency of 1000Hz and a duty cycle of 60%.

[0050] After the magnesium alloy workpiece is clamped by a hanger, it is immersed in the above solution and then subjected to micro-arc oxidation treatment. In the micro-arc oxidation process, the magnesium alloy workpiece was oxidized with a constant current of 1.5 amps / square decimeter for 16 minutes at first, and the voltage gradually increased from 0 volts to 400...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com