biodegradable polymer composition

A biodegradable polyester and biodegradable technology, applied in the field of preparing these polymer compositions, can solve the problem of bubbling instability, shear sensitivity, poor melt strength, polymer melt viscosity, increased scrap rate, increased processing costs, etc. problems, achieve excellent biodegradability and improve processing performance

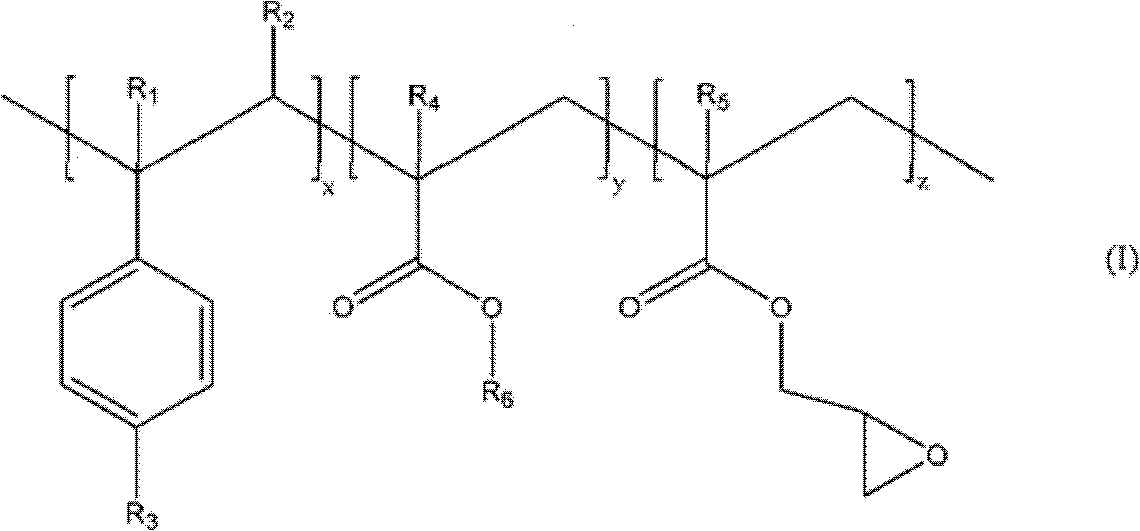

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] Embodiment 1: the preparation of masterbatch

[0115] 35kg of acetate starch (starch acetate) with a moisture content of less than 1wt% (DS is 0.5), 8.5kg of poly(butylene adipate / terephthalate) (PBAT), 14kg of glycerin , 6 kg of sorbitol, 1.2 kg of distilled monoglyceride (GMS), 6 kg of ethylene-acrylic acid copolymer (EAA) (9% acid value, melt flow index=20), 3 kg of ethylene-vinyl acetate ( EVA), 0.2 kg of sodium stearate and 0.12 kg of sodium hydroxide dissolved in a minimum amount of water were melt mixed in a ZSK-65 twin-screw extruder (L / D=48). Before melt blending the components, the solid materials are dry blended in a high speed blender and then the liquid materials are added to distribute all components evenly. The temperature profile of the extruder was set at 100°C / 130°C / 160°C / 160°C / 150°C / 140°C. The screw speed was set at 300 rpm. The extrusion process uses a vacuum of -0.06 to -0.08 bar. The molten polymer is extruded in strands and cut into pellets af...

Embodiment 2

[0116] Embodiment 2: Preparation of biodegradable polymer composition

[0117] First, the master batch prepared in Example 1 containing 30wt%, 52.7wt% of PBAT, 7wt% of polycaprolactone (PCL), 3wt% of polylactic acid (PLA), 2wt% of GMS, 0.3wt% of poly Epoxide ( The composition of ADR-4368) and 5wt% talc was dry blended first, and then melt mixed in a ZSK-65 twin-screw extruder with a rotation speed of 200 rpm. The temperature profile of the extruder was set at 80°C / 130°C / 170°C / 170°C / 160°C / 130°C. The extrusion process uses a vacuum of -0.04 to -0.05 bar. The resulting extrudate was water cooled and cut into pellets and found to have a melt flow index of 7 g / 10 min measured on 2.16 kg of fluid at 190°C.

[0118] The polymer composition prepared according to Example 2 was blown into a film with a thickness of 20 microns on a standard LDPE blown film production line, and the process conditions are shown in the table below.

[0119] Processing Conditions - Blown Film

[0120]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com