Yeast-displayed polygalacturonase combined with ultrasonic treatment to extract laver polysaccharides

A technology of polygalactose and laver polysaccharides, which is applied in the field of bioengineering, can solve the problems of affecting the efficiency of laver cell crushing, less research on extracting laver polysaccharides, and inactivation of active substances, so as to achieve high product purity, short operation time, and extraction yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

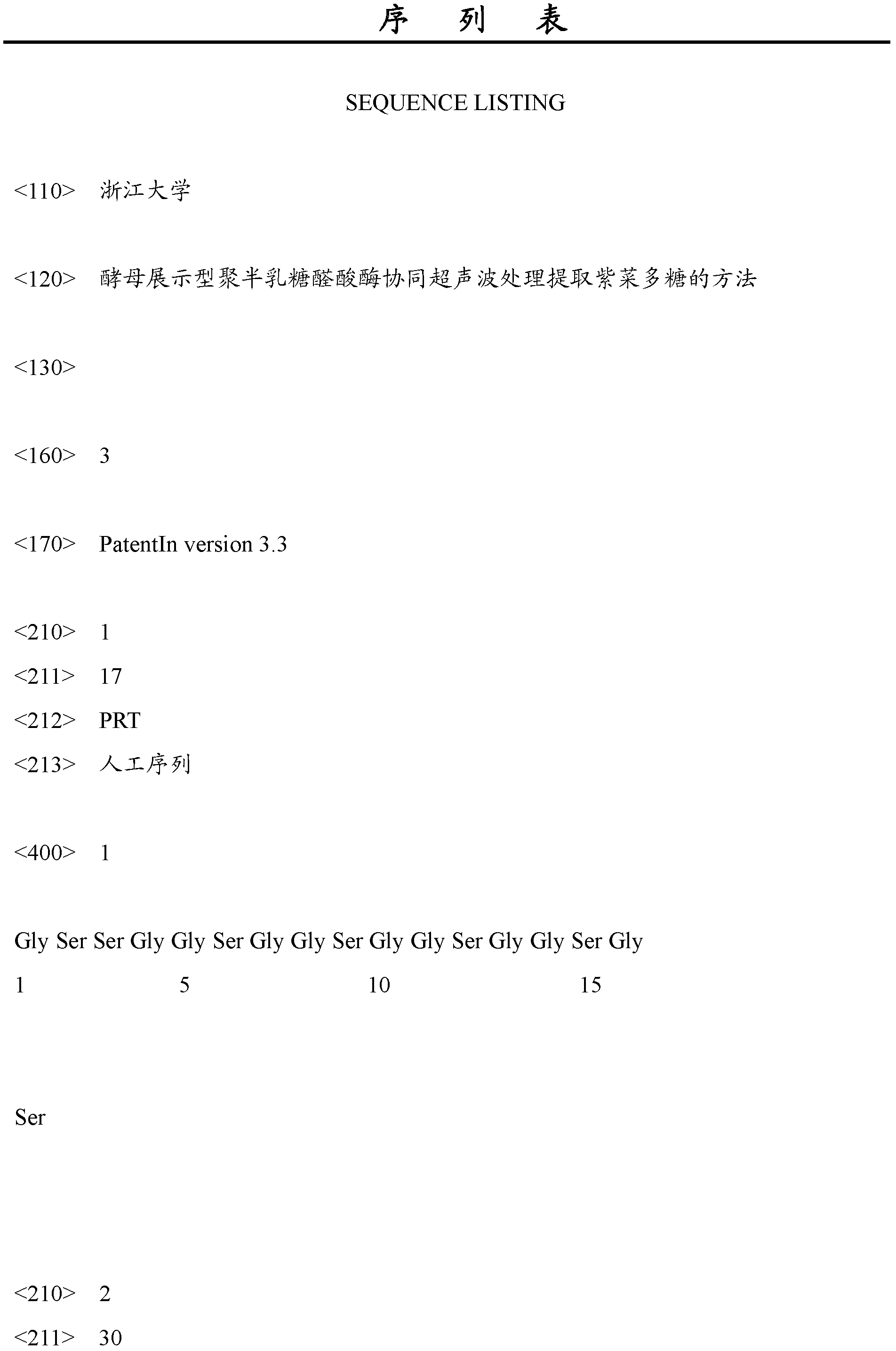

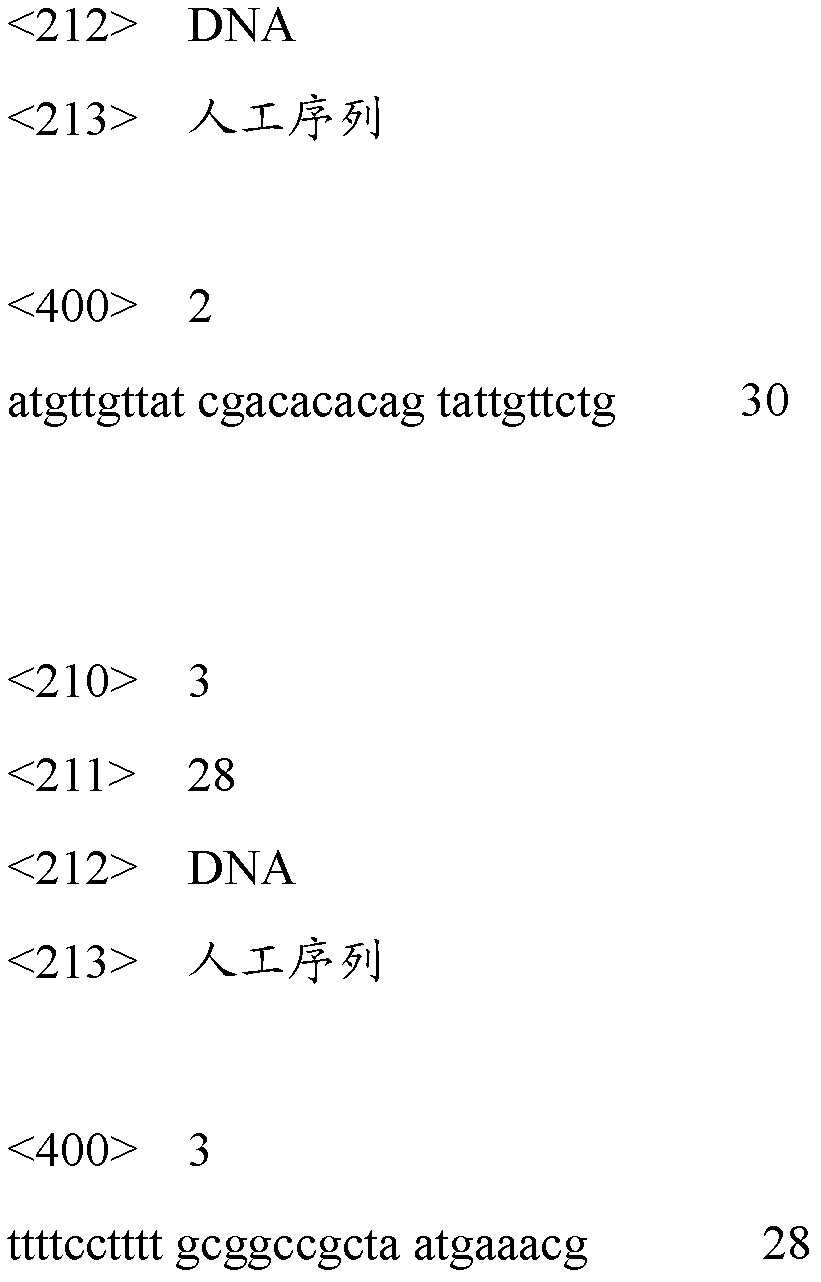

[0023] Preparation of Yeast Display Polygalacturonase

[0024] Synthesize the polygalacturonase gene (Genbank No.: HQ446162.1) and the cell wall α-lectin gene of Pichia pastoris GS115 (Genbank No.: M28164) by artificial synthesis. At the same time, polygalacturonase gene C The connecting peptide sequence GSSGGSGGSGGSGGSGS(linker) is added to the end, and the nucleotide sequence PGA-linker-α-agglutinin is obtained after connection, and EcoR I and Not I enzyme cutting sites are added at both ends of the sequence, wherein PGA is polygalacturonic acid Enzyme gene, α-agglutinin is cell wall α lectin gene.

[0025] Using the above artificially synthesized sequence as a template, PCR amplification was performed using the following primer pair,

[0026] Upstream primer: 5'-ATGTTGTTATCGACACACAGTATTGTTCTG-3';

[0027] Downstream primer: 5'-TTTTCCTTTTGCGGCCGCTAATGAAACG-3'

[0028] The PCR reaction system is: 1 μl of template DNA, 0.5 μl of high-fidelity DNA polymerase, 0.4 μl of dNTP ...

Embodiment 1

[0035] Example 1 Take 20 grams of laver dry powder with a particle size of 60 mesh and add it to 1000 grams of water, mix well, and prepare a suspension; then add 1 gram of yeast display polygalacturonase prepared according to the above method, and stir at 35°C React for 30 minutes with a stirring rate of 100 rpm; carry out ultrasonic crushing with an ultrasonic power of 730W, an ultrasonic treatment time of 65 minutes, and an ultrasonic treatment temperature of 30°C; centrifuge at 5000g for 10 minutes to remove the precipitate, and obtain the porphyra containing laver content. Supernatant: Add ammonium sulfate in the supernatant, make the concentration of ammonium sulfate in the supernatant reach 20% (W / V), leave standstill 12 hours in 4 ℃; Through 5000g centrifugation 10 minutes, remove precipitation, obtain containing A solution of laver polysaccharides.

[0036] The above method for determining the yield of laver polysaccharides was used to detect the extraction yield of l...

Embodiment 2

[0037] Example 2 Take 25 grams of laver dry powder with a particle size of 100 mesh and add it to 1000 grams of water, mix well, and prepare a suspension; then add 2 grams of yeast-displayed polygalacturonase prepared according to the above method, and stir at 37°C React for 45 minutes, the stirring rate is 200 rpm; carry out ultrasonic crushing, the ultrasonic power is 750W, the ultrasonic treatment time is 85 minutes, and the ultrasonic treatment temperature is 35°C; after centrifugation at 5000g for 10 minutes, the precipitate is removed to obtain the laver content. Supernatant: Add ammonium sulfate in the supernatant, make the concentration of ammonium sulfate in the supernatant reach 25% (W / V), leave standstill 12 hours in 4 ℃; Through 5000g centrifugal 10 minutes, remove precipitation, obtain containing A solution of laver polysaccharides.

[0038] The above method for determining the yield of laver polysaccharides was used to detect the extraction yield of laver polysac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com