Carbon heterostructure material/β-cyclodextrin composite modified electrode and preparation method

A technology of heterostructure and modified electrodes, applied in the field of electrochemical analysis and detection, can solve the problems of reducing the conductivity of graphene, destroying the lattice structure of graphene, etc., achieving good repeatability and reproducibility, broad application prospects, and manufacturing process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of graphite oxide

[0026] Add 1g of graphite to 2mL of concentrated sulfuric acid with a concentration of 95wt%, 0.5g of potassium persulfate, and 0.5g of phosphorus pentoxide, react at 75°C for 5h, and centrifuge the product for 0.5h at a speed of 3000r·min -1 ,, washed with deionized water to pH 6.8, dried at 30 ° C to obtain pre-oxidized graphite. Add 0.2g of pre-oxidized graphite to 5mL of concentrated sulfuric acid with a concentration of 95wt%, stir at 0°C, slowly add 0.6g of potassium permanganate, stir and react at 35°C for 1h, raise the temperature to 90°C, and add 10mL of deionized Water, after the reaction is completed, add 28mL water and 0.5mL, 30wt% hydrogen peroxide mixture, filter, wash the product with 50mL, 3.6wt% hydrochloric acid solution until there is no sulfate ion, filter, and dry at 30°C to obtain oxidised graphite.

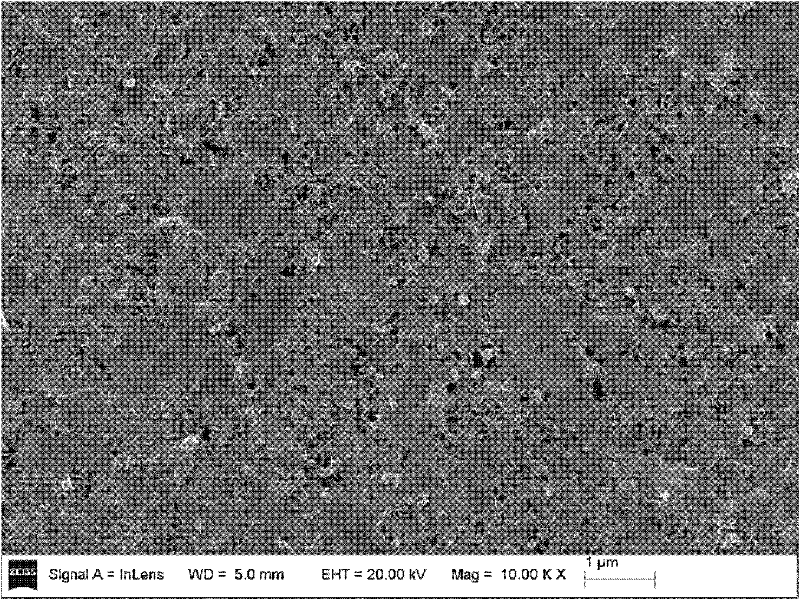

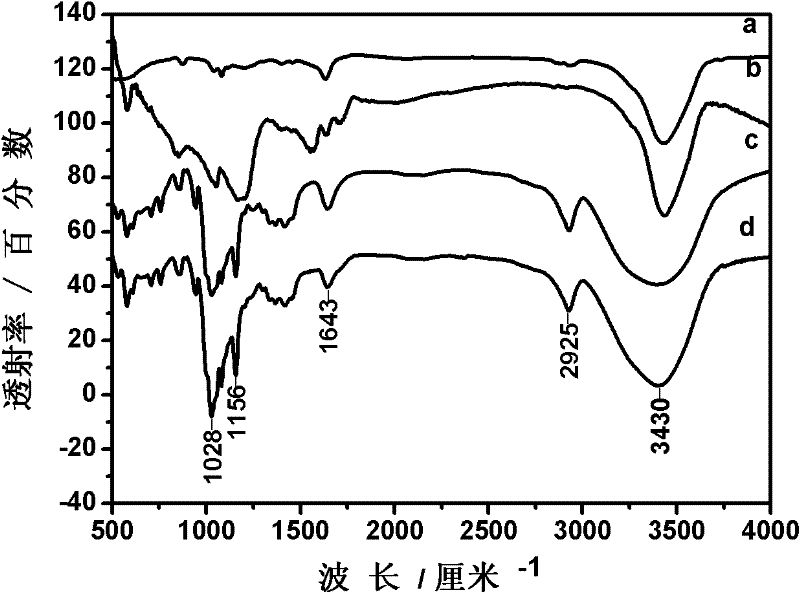

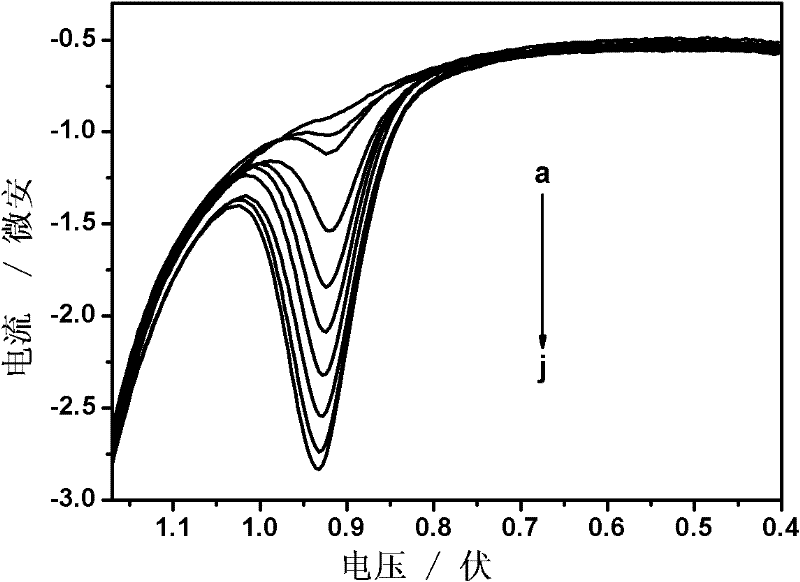

[0027] (2) Preparation of carbon heterostructure material / β-cyclodextrin complex modified electrode

[0028] A...

Embodiment 2

[0035] (1) Preparation of graphite oxide

[0036] Add 2g of graphite to 5mL of concentrated sulfuric acid with a concentration of 96wt%, 1g of potassium persulfate, and 1g of phosphorus pentoxide, react at 76°C for 6h, and centrifuge the product for 1h at a speed of 4000r·min -1 , washed with deionized water to pH 7.0, and dried at 35°C to obtain pre-oxidized graphite. Add 0.6g of pre-oxidized graphite to 15mL of concentrated sulfuric acid with a concentration of 96wt%, stir at 1°C, slowly add 1.8g of potassium permanganate, stir and react at 38°C for 1h, raise the temperature to 92°C, add 30mL of deionized Water, after the reaction is completed, add 84mL of water and 1.5mL, 30wt% hydrogen peroxide mixture, filter, wash the product with 150mL, 3.7wt% hydrochloric acid solution until there is no sulfate ion, filter, and dry at 35°C to obtain oxidised graphite.

[0037] (2) Preparation of carbon heterostructure material / β-cyclodextrin complex modified electrode

[0038] A. Ta...

Embodiment 3

[0044] (1) Preparation of graphite oxide

[0045] Add 4g of graphite to 8mL of concentrated sulfuric acid with a concentration of 97wt%, 2g of potassium persulfate, and 2g of phosphorus pentoxide, react at 78°C for 7h, and centrifuge the product for 1.5h at a speed of 5000r·min -1 ,, washed with deionized water to pH 7.2, dried at 40 ° C to obtain pre-oxidized graphite. Add 1g of pre-oxidized graphite to 25mL of concentrated sulfuric acid with a concentration of 97wt%, stir at 2°C, slowly add 2.4g of potassium permanganate, stir and react at 40°C for 1.5h, raise the temperature to 95°C, and add 50mL of deionized Water, after the reaction is completed, add 140mL of water and 2.5mL, 30wt% hydrogen peroxide mixture, filter, wash the product with 250mL, 3.6wt% hydrochloric acid solution until there is no sulfate ion, filter, and dry at 40°C to obtain oxidised graphite.

[0046] (2) Preparation of carbon heterostructure material / β-cyclodextrin complex modified electrode

[0047]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com