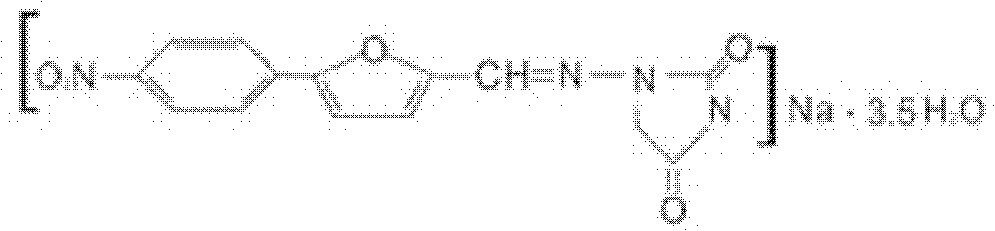

Dantrolene sodium freeze-dried powder injection for injection and preparation method thereof

A technology for freeze-dried powder injection and dantrolene sodium, applied in the field of medicine, can solve the problems of poor resolubility of dantrolene sodium freeze-dried powder for injection, poor water solubility of dantrolene sodium, low bioavailability and the like, and achieves considerable Economic and social benefits, short administration time, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] [embodiment 1] the preparation of dantrolene sodium crystal

[0084] 1) Dissolving dantrolene sodium in a propylene glycol solvent to make a concentration of 10% dantrolene sodium solution is placed in a reactor in a constant temperature water bath with a temperature of 5° C.;

[0085] 2) Turn on the agitator, add the dantrolene sodium solution into water at a rotating speed of 2000r / min, stir for 18min to form a slurry, wherein the volume ratio of the dantrolene sodium solution to water is 1:20;

[0086] 3) The obtained slurry was left to stand for 3 hours, vacuum filtered and dried to obtain dantrolene sodium crystals.

[0087] According to FT-IR analysis, the molecular structure of dantrolene sodium did not change before and after ultra-micronization;

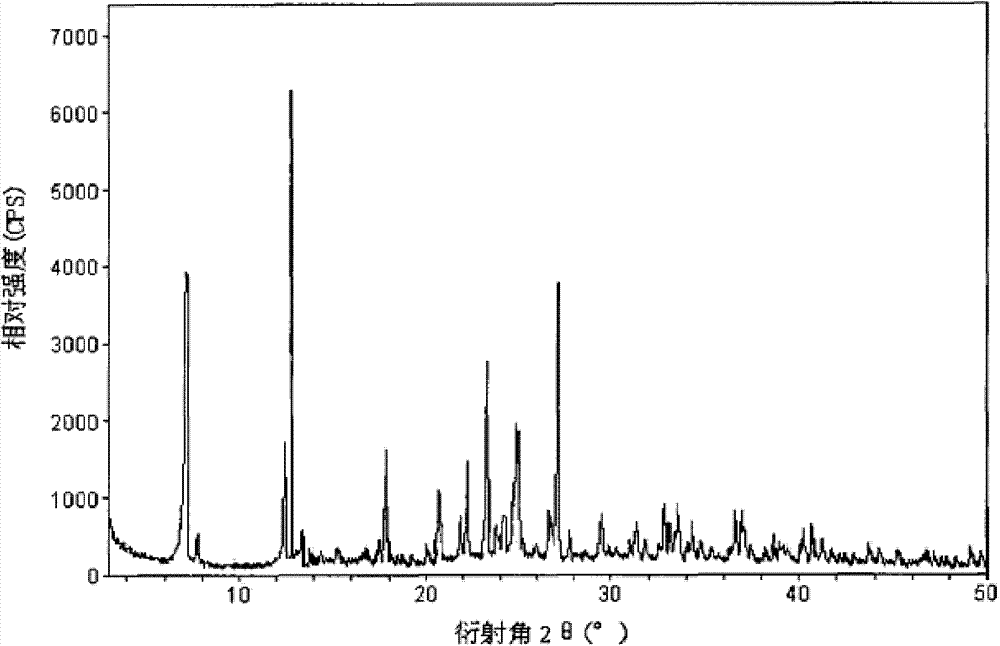

[0088] The X-ray powder diffraction spectrogram (XRD spectrogram) that uses Cu-K α ray measurement to the prepared dantrolene sodium crystal is shown in figure 1 , whose characteristic peaks are displayed at 2θ of 7...

Embodiment 1

[0093] [Preparation Example 1] Dantrolene Sodium Freeze-Dried Powder for Injection

[0094] Prescription: per 1000 prescriptions

[0095]

[0096] Preparation Process:

[0097] 1) take the dantrolene sodium and lactose of prescription quantity;

[0098] 2) Add 6000ml of water for injection and prescribed amount of dantrolene sodium into the liquid preparation tank, then add the prescribed amount of lactose, and fully stir to dissolve;

[0099] 3) adjust the pH value of the solution to 9.7 with 1mol / L sodium bicarbonate;

[0100] 4) Add water for injection to make up to 8000ml, and mix well;

[0101] 5) Add 0.03% activated carbon to the clear solution, stir and absorb for 30 minutes, then use a 0.45 μm microporous membrane filter to decarbonize, filter through a 0.45 μm primary sterile filter, and filter through a 0.45 μm secondary terminal sterile filter. In the liquid bottle, take the above-mentioned medicinal liquid to measure the content and pH value of the semi-fini...

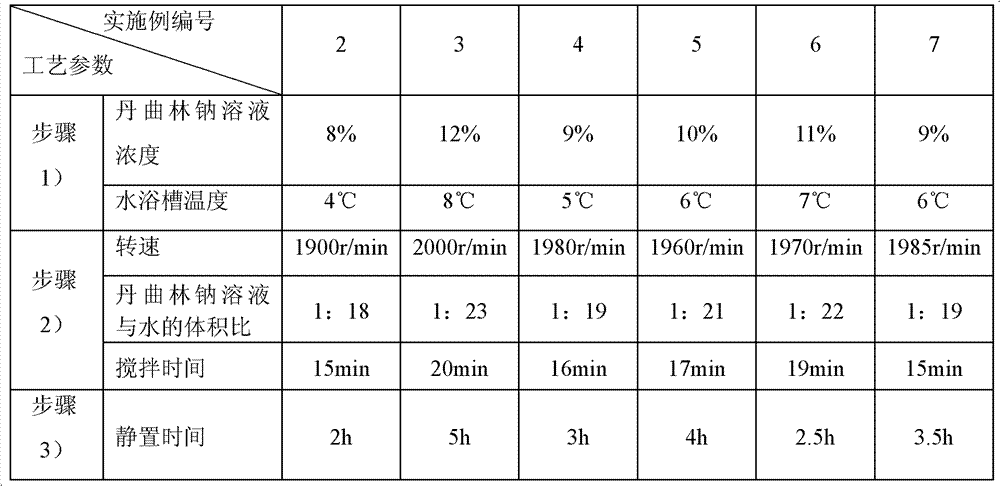

Embodiment 2

[0107] [Preparation Example 2] Dantrolene Sodium Freeze-Dried Powder for Injection

[0108] Prescription: per 1000 prescriptions

[0109]

[0110] Preparation process: the specific operation steps are the same as in Example 1, and the difference from Example 1 is that the freeze-drying in step 6) is:

[0111] Pre-freezing stage: reduce the temperature of the shelf to -48°C at a rate of 0.70°C / min, and after the temperature of the subpackaged filtrate product drops to -35°C, continue to keep warm for 4 hours, and the temperature of the cold hydrazine drops rapidly below -50°C. Open the well valve of the box and evacuate until the vacuum in the box reaches about 10pa;

[0112] Primary drying stage: Slowly raise the shelf temperature to -2°C at a rate of 0.30°C / min, keep warm, and keep warm for 4 hours after the ice crystals of the product in the primary drying completely disappear;

[0113] Secondary drying stage: raise the temperature of the shelf to 17°C at a rate of 0.53...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com