Method for recovering oxytetracycline from oxytetracycline hydrochloride waste liquid

A technology of oxytetracycline hydrochloride and oxytetracycline, which is applied in the separation/purification of carboxylic acid amides, organic chemistry and other directions, can solve the problems of increasing environmental protection and pollution control costs, wasting raw material oxytetracycline, and consuming large funds, so as to reduce pollution The effect of total waste, easy disposal, and low recovery cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

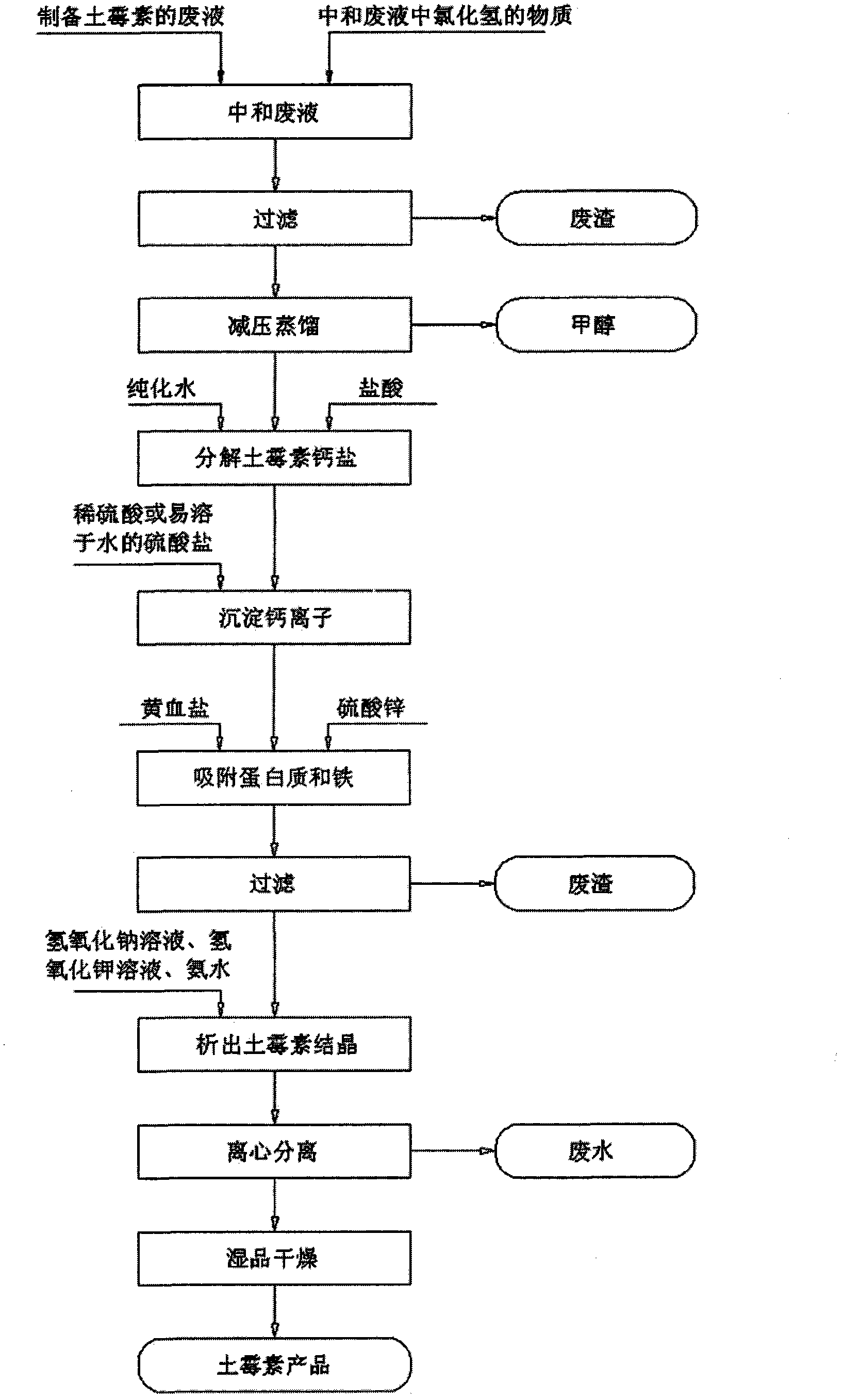

[0020] Embodiment 1: as figure 2 Shown, a kind of method that reclaims oxytetracycline from oxytetracycline hydrochloride waste liquid comprises the following steps successively:

[0021] (a) Neutralize and filter the waste liquid: stir slowly and evenly add calcium carbonate (industrial grade) into the waste liquid for preparing oxytetracycline hydrochloride, adjust the pH to 4.0, and press filter to obtain the filtrate;

[0022] (b) Distillation and recovery of methanol: the filtrate is controlled at a temperature of 50° C. and a vacuum of 0.06 MPa to recover methanol by distillation under reduced pressure;

[0023] (c) Decompose oxytetracycline calcium: add purified water to the remaining liquid after distillation, stir and add hydrochloric acid (industrial grade), adjust the pH to 1.0;

[0024] (d) Precipitating calcium ions: stirring and adding anhydrous sodium sulfate (industrial grade), and stirring for 10 minutes after adding;

[0025] (e) Adsorption of protein and ...

Embodiment 2

[0028] Embodiment 2: as figure 2 Shown, a kind of method that reclaims oxytetracycline from oxytetracycline hydrochloride waste liquid comprises the following steps successively:

[0029] (a) Neutralize and filter the waste liquid: stir slowly and evenly add sodium bicarbonate (industrial grade) into the waste liquid for preparing oxytetracycline hydrochloride, adjust the pH to 4.20 and filter to obtain the filtrate;

[0030] (b) Distillation and recovery of methanol: the filtrate is controlled at a temperature of 60° C. and a vacuum of 0.05 MPa to recover methanol by distillation under reduced pressure;

[0031] (c) Decompose oxytetracycline calcium: add purified water to the remaining liquid after distillation, stir and add hydrochloric acid (industrial grade), adjust the pH to 0.7;

[0032] (d) Precipitating calcium ions: Stir and add ammonium sulfate (industrial grade), and stir for 15 minutes after adding;

[0033] (e) Adsorption of protein and iron: stirring and addin...

Embodiment 3

[0036] Embodiment 3: as figure 2 Shown, a kind of method that reclaims oxytetracycline from oxytetracycline hydrochloride waste liquid comprises the following steps successively:

[0037] (a) Neutralize and filter the waste liquid: stir slowly and evenly add ammonium bicarbonate (industrial grade) into the waste liquid for preparing oxytetracycline hydrochloride, adjust the pH to 4.40 and filter to obtain the filtrate;

[0038] (b) Distillation and recovery of methanol: the filtrate is controlled at a temperature of 40°C and a vacuum of 0.07MPa to recover methanol by distillation under reduced pressure;

[0039] (c) Decompose oxytetracycline calcium: add purified water to the remaining liquid after distillation, stir and add hydrochloric acid (industrial grade), adjust the pH to 0.75;

[0040] (d) Precipitating calcium ions: stirring and adding potassium sulfate (industrial grade), stirring for 20 minutes after adding;

[0041] (e) Adsorption of protein and iron: stirring a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com