Intercalation preparation method of nylon 6/quaternary phosphonium salt modified montmorillonite nano composite material

A technology of nanocomposite materials and quaternary phosphonium salts, which is applied in the field of intercalation preparation, can solve the problems of difficulty in realizing nano-effects, low thermal decomposition temperature of quaternary ammonium salts, and detachment of intercalation agents, so as to solve the discoloration and thermal stability of nylon 6 resin The effect of high stability and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

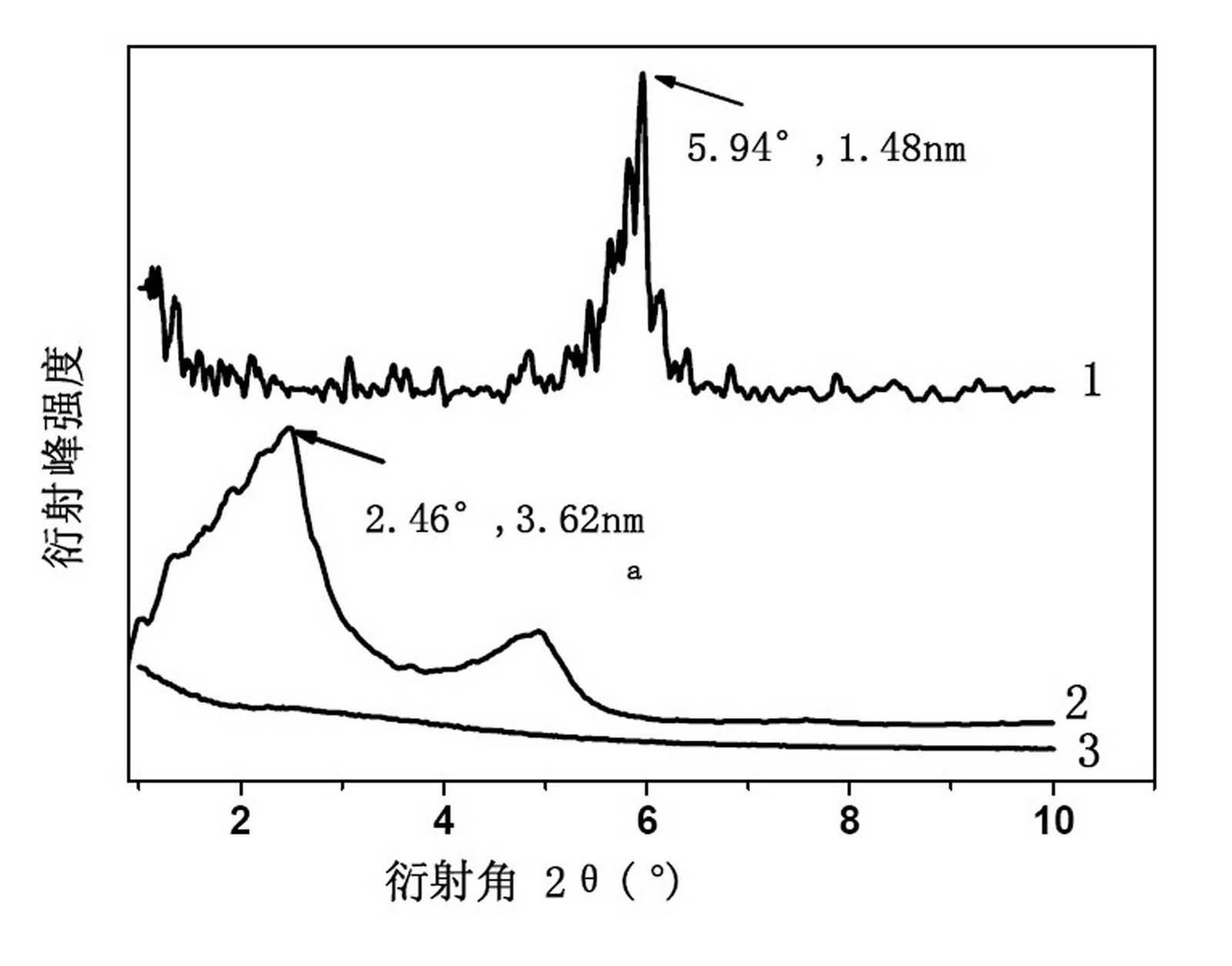

[0021] A kind of intercalation preparation method of nylon 6 / quaternary phosphonium salt modified montmorillonite nanocomposite material, comprises the following steps:

[0022] 1) Add quaternary phosphonium salt and sodium montmorillonite into water at a mass ratio of 1:3-5, and stir at 60-100°C for 4-8 hours;

[0023] 2) Filtrating the solution in step 1), washing the obtained solid, drying, grinding, and sieving to obtain a quaternary phosphonium salt intercalation-modified montmorillonite;

[0024] 3) Take the quaternary phosphonium salt intercalation-modified montmorillonite and caprolactam in step 2), add them into the reaction kettle, stir evenly at room temperature, add water, benzoic acid, and isophthalic acid into the reaction kettle, and carry out the reaction under the protection of inert gas. Hydrolysis polymerization reaction, the reaction temperature is 250-260°C, the reaction time is 6-8h, after the reaction, pelletize to obtain slices of nylon 6 / montmorillonit...

Embodiment 1

[0029] A kind of intercalation preparation method of nylon 6 / quaternary phosphonium salt modified montmorillonite nanocomposite material, comprises the following steps:

[0030] 1) Weigh 200g of sodium montmorillonite powder and 60g of octadecyltributylphosphonium bromide, add them to 1L of distilled water, stir the above solution at 80°C for 360min, and carry out organic intercalation of montmorillonite Reactive modification;

[0031] 2) vacuum filter the above solution, wash the obtained solid with deionized water, vacuum dry, grind, and pass through a 300-mesh sieve, and the obtained solid is quaternary phosphonium salt intercalation modified montmorillonite;

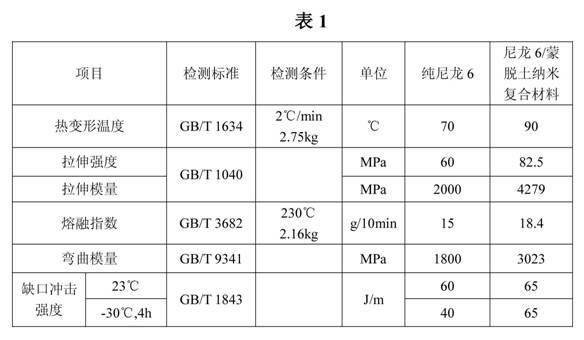

[0032] 3) Weigh 150g of the above-mentioned quaternary phosphonium salt modified montmorillonite and 3000g of caprolactam, add them into the reaction kettle, stir evenly at room temperature, add water, benzoic acid and isophthalic acid into the reaction kettle, the quality of the added water is 6% of caprolactam, th...

Embodiment 2

[0036] A kind of intercalation preparation method of nylon 6 / quaternary phosphonium salt modified montmorillonite nanocomposite material, comprises the following steps:

[0037] 1) Weigh 180g of sodium montmorillonite powder and 60g of octadecyltributylphosphonium bromide, add them to 1L of distilled water, stir the above solution at 60°C for 4h, and carry out organic intercalation of montmorillonite Reactive modification;

[0038] 2) vacuum filter the above solution, wash the obtained solid with deionized water, vacuum dry, grind, and pass through a 300-mesh sieve, and the obtained solid is quaternary phosphonium salt intercalation modified montmorillonite;

[0039] 3) Weigh 150g of the above-mentioned quaternary phosphonium salt modified montmorillonite and 2700g of caprolactam, add them into the reaction kettle, stir evenly at room temperature, add water, benzoic acid and isophthalic acid into the reaction kettle, the quality of the added water is The mass of caprolactam i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com