Preparation method for novel lithium vanadium phosphate/bamboo charcoal composite cathode material

A composite cathode material, lithium vanadium phosphate technology, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as the shortcomings of lithium vanadium phosphate cannot be completely overcome, and achieve the effects of rich pore size, improved rate performance, and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

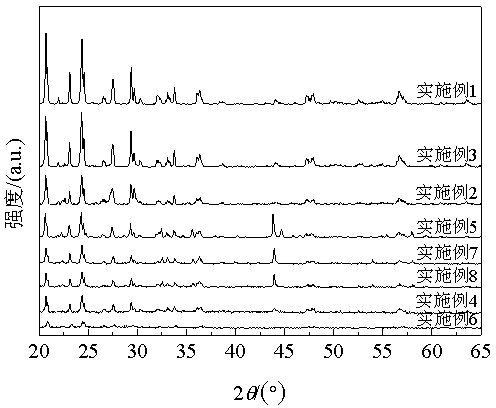

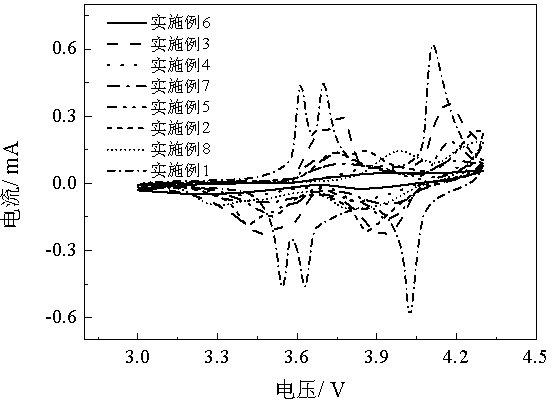

[0028] Dissolve vanadium pentoxide, lithium hydroxide, ammonium dihydrogen phosphate and citric acid in a certain amount of deionized water at a molar ratio of 1:3:3:2, stir thoroughly in a water bath at 50°C for 5 hours, and then add activation The final (content is 10%) bamboo charcoal (bamboo joints) (the specific activation process of bamboo charcoal is: dry distillation carbonization (argon protection, carbonization temperature 800 ℃, carbonization time 6 h) after the bamboo charcoal is fully mixed with KOH, the mass ratio is 1 : 4, the microwave activation time is 5 min.), and the water was evaporated until the sol was formed, and the lithium vanadium phosphate precursor was obtained after drying in a vacuum oven at 120 °C for 8 h. The precursor was ground into a mold, pressed into a round cake under a pressure of 4 MPa, then placed in a porcelain boat covered with conductive carbon black (SP) powder, heated in a microwave oven at 640 W for 14 min, and cooled to At room ...

Embodiment 2

[0030] Dissolve vanadium pentoxide, lithium hydroxide, ammonium dihydrogen phosphate and salicylic acid in a certain amount of deionized water at a molar ratio of 1:2.9:3:2.5, stir thoroughly in a water bath at 55 °C for 5 h, and then add Activated (3% content) bamboo charcoal (bamboo root) (bamboo charcoal activation process is the same as in Example 1), evaporate water to form a sol, and dry in a vacuum oven at 120 °C for 8 h to obtain a lithium vanadium phosphate precursor . The precursor was ground into a mold, then placed in a porcelain boat, covered with SP powder, heated in a 640 W microwave oven for 11 min, cooled to room temperature, taken out and ground to obtain a sample of bamboo charcoal-coated lithium vanadium phosphate.

Embodiment 3

[0032] Dissolve vanadium pentoxide, lithium carbonate, ammonium dihydrogen phosphate, and ascorbic acid in a molar ratio of 1:1.5:3:2 in a certain amount of deionized water, fully stir in a water bath at 50 °C for 5 h, and then add activated (5% content) bamboo charcoal (bamboo diameter) (bamboo charcoal activation process is the same as in Example 1), and evaporate water to form a sol, and dry in a vacuum oven at 120 °C for 8 h to obtain a lithium vanadium phosphate precursor. Grind this precursor into a mold, press it into a round cake under a pressure of 4 MPa, then place it in a porcelain boat, cover it with SP powder, heat it in a microwave oven at 640 W for 15 min, cool it to room temperature, take it out and grind it A sample of bamboo charcoal-coated lithium vanadium phosphate was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com