Method for improving water-soluble dietary fibers in bean dregs

A dietary fiber, water-soluble technology, applied in food preparation, food science, application, etc., can solve the problems of expensive equipment, nutrient damage, difficulty in pressurizing the extrusion cavity, etc., and achieve the speed of reducing extrusion temperature and screw speed, The effect of enhancing polysaccharide depolymerization and transglycosylation, and reducing the decrease of sensory properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

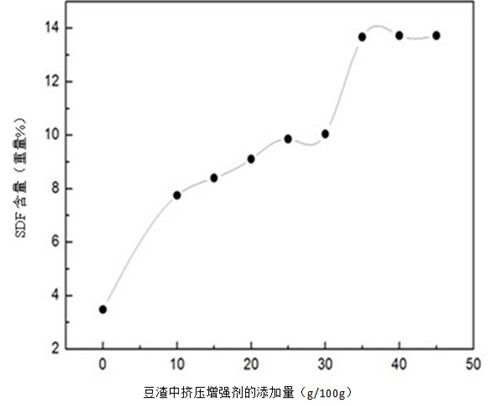

[0053] Example 1 Investigation of the influence of citric acid and sodium bicarbonate on SDF components in bean dregs

[0054] The length of the barrel is 1.4m, and the diameter of the barrel hole is 5.7cm. It includes four heating sections. The temperatures of the first three heating sections are fixed at 50, 70, and 110°C respectively, and the temperature of the fourth heating section is the extrusion temperature. , each segment is 12.8cm long. The arrangement of the pitch in the screw gradually decreases along the direction of the die, and the pitch near the end of the die increases instead.

[0055] 1 Material: Weigh 9 parts of bean dregs powder, add 30 g of water to 100 g of bean dregs powder, and add extrusion enhancer (citric acid and sodium bicarbonate in a weight ratio of 1:1) to 0 g, 10 g, 15 g, 20 g, 25 g, The ratio of 30g, 35g, 40g, 45g is mixed and stirred evenly with bean dregs powder, extrusion enhancer, and water, and the material is obtained, and each materia...

Embodiment 2

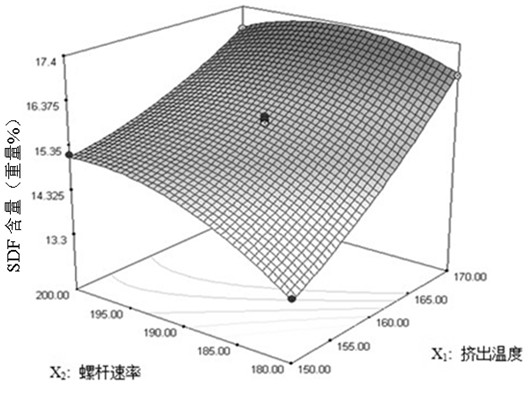

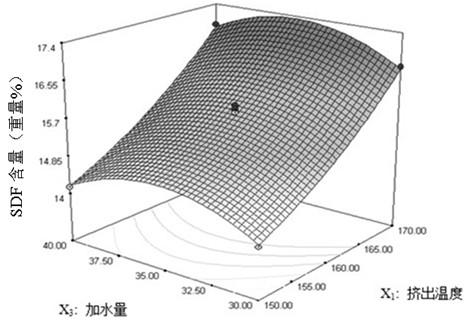

[0058] Example 2 Response surface analysis optimizes the process of increasing dietary fiber in bean dregs

[0059] According to the Box–Behnken design (BBD) principle of the central combined test design and the single factor test results, the feed amount of each batch is 400g, the feed rate is 200g / min, and the temperatures of the first three heating sections in the extrusion process are respectively fixed at 50, 70, 110°C (extrusion process temperature is 50-70-110°C), the temperature of the fourth heating zone is the extrusion temperature, and the amount of extrusion enhancer added is 35g / 100g. Three factors that have a significant impact on the SDF content in bean dregs are selected as independent variables: extrusion temperature, screw speed and water addition. Each independent variable takes three levels, coded by -1, 0, and 1 respectively, and the three factors in bean dregs The SDF content was the response value, and Design Expert 7.0 software was used to design the re...

Embodiment 3

[0071] Example 3 Improvement of SDF in bean dregs

[0072] like Figure 5 The production process flow chart of adding extrusion enhancer is shown in the figure;

[0073] a. Preparation of feed: Wash and dry the bean dregs, crush the dried bean dregs, pass through a 60-mesh sieve, weigh 400 g of sieved powder and 70 g of citric acid powder, then add 140 g of distilled water, stir evenly, and balance at a temperature of 25°C for 20 Minutes to prepare the feed.

[0074]B. Feeding and extruding: Add 70g of sodium bicarbonate to the feed obtained in step a, after stirring evenly, send it into the extruder, the amount of feed per batch is 400g, and the feed rate is 200g / min, adjust the extruder In the working state, the screw speed is 180 rpm, the extrusion process temperature is 50-70-110°C, the extrusion temperature is 150°C, and the material is produced;

[0075] c. Post-processing: collect the material obtained in step b, and cool for 10 minutes. Store in an oven at 60°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com