Homogeneous anion exchange membrane and preparation method thereof

An anion exchange membrane and atom transfer technology, applied in the field of homogeneous anion exchange membrane and its preparation, can solve the problems of complex equipment, low grafting efficiency, and increased cost, and achieve high conductivity, easy preparation process, and excellent reaction conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention discloses a preparation method of a homogeneous anion exchange membrane, which comprises the following steps:

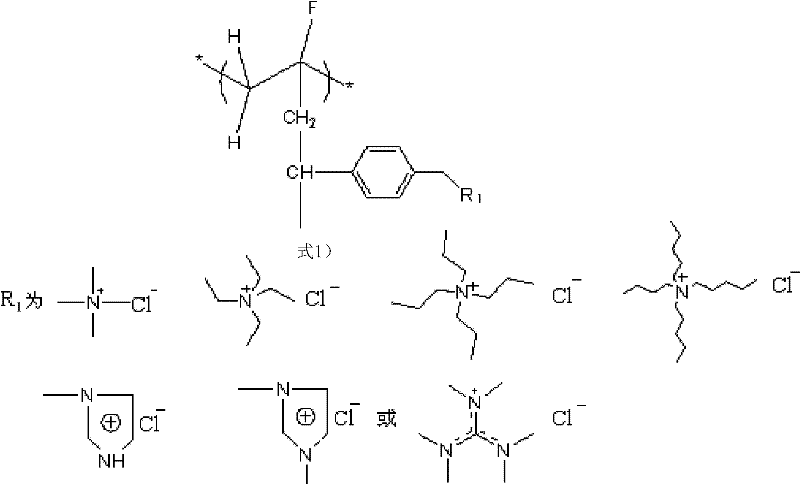

[0027] Add p-chloromethylstyrene to the non-aqueous solution of the basic functionalization reagent, and obtain the basic functionalization monomer after the reaction, and the basic functionalization reagent is trimethylamine, triethylamine, tripropylamine, tributylamine, Imidazole, 1-methylimidazole or guanidine compounds;

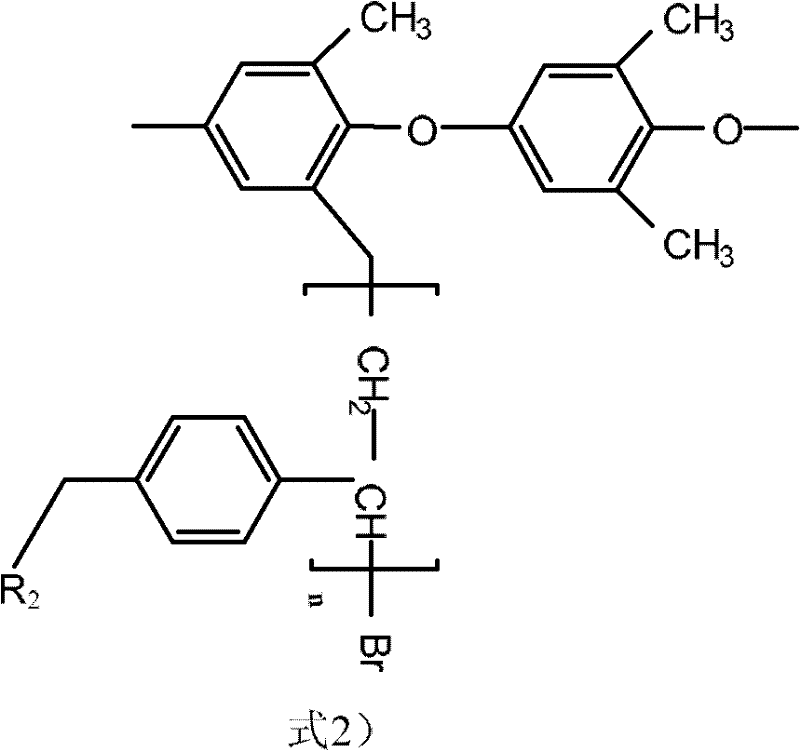

[0028] Under the action of a catalyst, the first reaction raw material and the basic functionalized monomer are subjected to atom transfer radical polymerization to obtain a graft polymer, and the first reaction raw material is polyvinylidene fluoride or bromomethylated Poly(1,4-dimethyl-2,6-phenylene oxide);

[0029] The graft polymer is dissolved in the first solvent to obtain a casting solution, and the anion exchange membrane is obtained after coating and casting the casting solution to form a membrane.

[0030] In the...

Embodiment 1

[0051] 1. Preparation of monomer: Collect trimethylamine gas with acetone solvent to obtain acetone solution of trimethylamine with a concentration of 5.0mol / L; measure 123.9mL (0.620mol) of the above solution and place it in a 500mL container with a mechanical stirring device In the three-necked flask; slowly add 30mL (0.207mol) p-chloromethylstyrene (VBC) dropwise into the three-necked flask using a constant pressure dropping funnel, and after reacting at room temperature for 10h, stop the mechanical stirring, and filter the reaction solution with suction , a white solid was obtained, and acetone was added to wash to remove unreacted p-chloromethylstyrene (VBC). This operation was repeated three times, and vacuum-dried at room temperature to obtain a basic functionalized monomer.

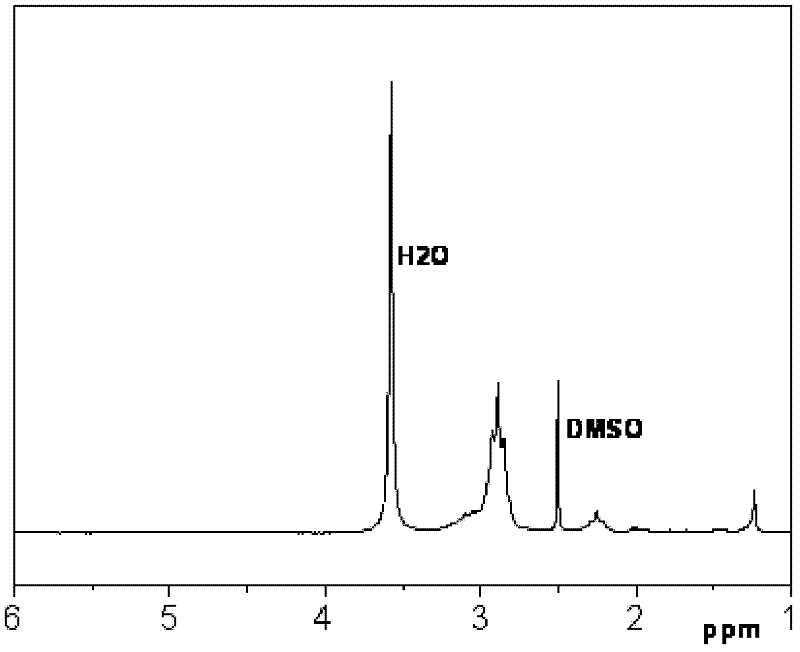

[0052] 2. Preparation of grafted polymer: Add 1g of polyvinylidene fluoride (PVDF), 3g of the prepared basic functionalized monomer and 174μL of pentamethyldiethylenetriamine (PMDETA) in a 100mL th...

Embodiment 2

[0057] 1. Preparation of monomer: the same preparation process as in Example 1 was adopted.

[0058] 2. Preparation of the polymer: the same preparation process as in Example 1 was adopted, and the mass of the basic functionalized monomer added was 4 g.

[0059] 3. Film formation: the same preparation process as in Example 1 was adopted.

[0060] After measurement, the water content of the homogeneous anion exchange membrane prepared in this example is 91.6%, the ion exchange capacity is 1.86mmol / g dry film, and the OH - The conductivity is 4.5×10 -2 S / cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com