Zinc-doped porous nano-titanium oxide coating and its preparation method

A nano-titanium oxide, zinc-doped technology, applied in coatings, surface reaction electrolytic coatings, electrolytic coatings, etc., can solve problems such as unreported, and achieve the effects of easy popularization and application, strong vitality and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

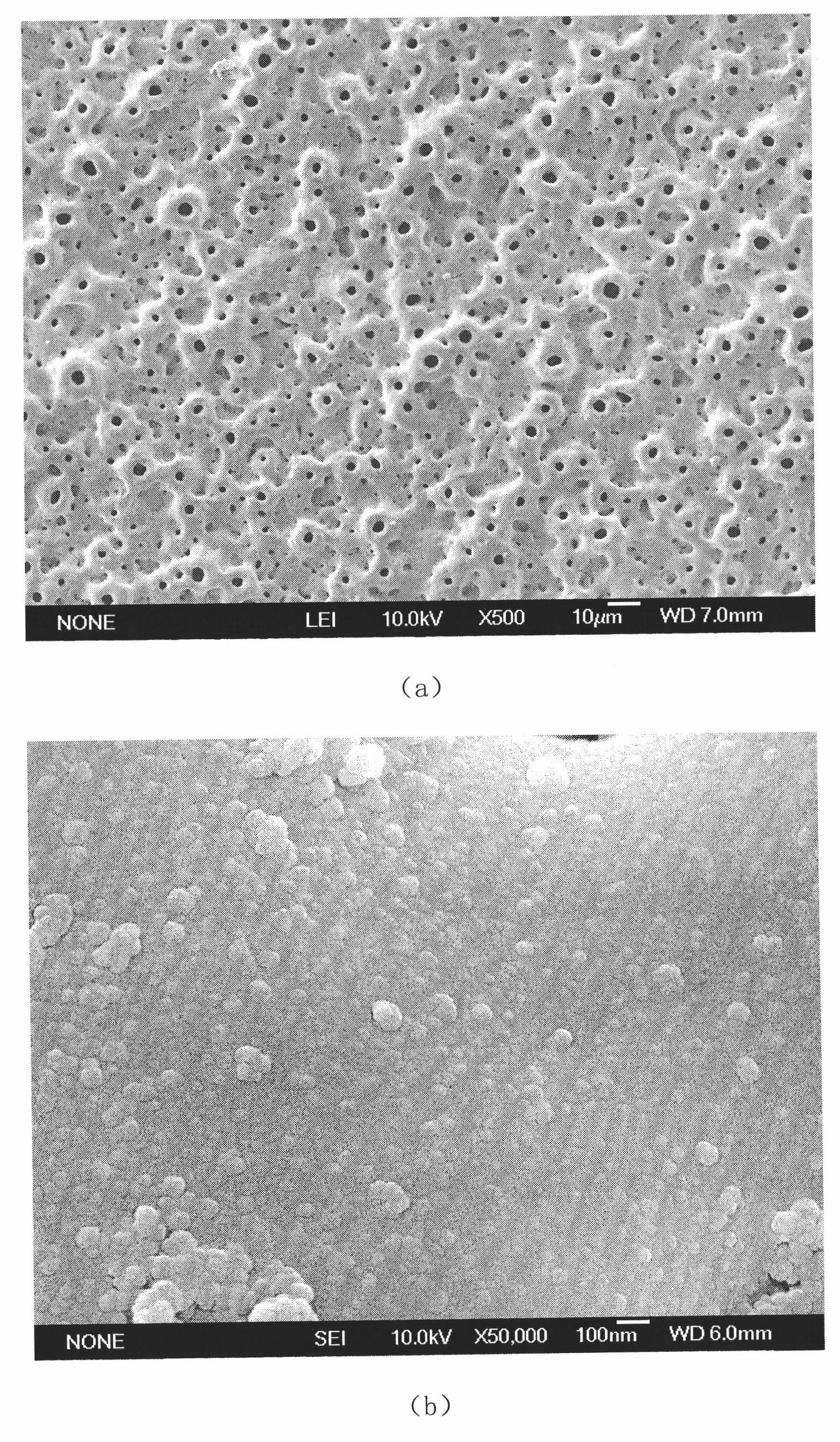

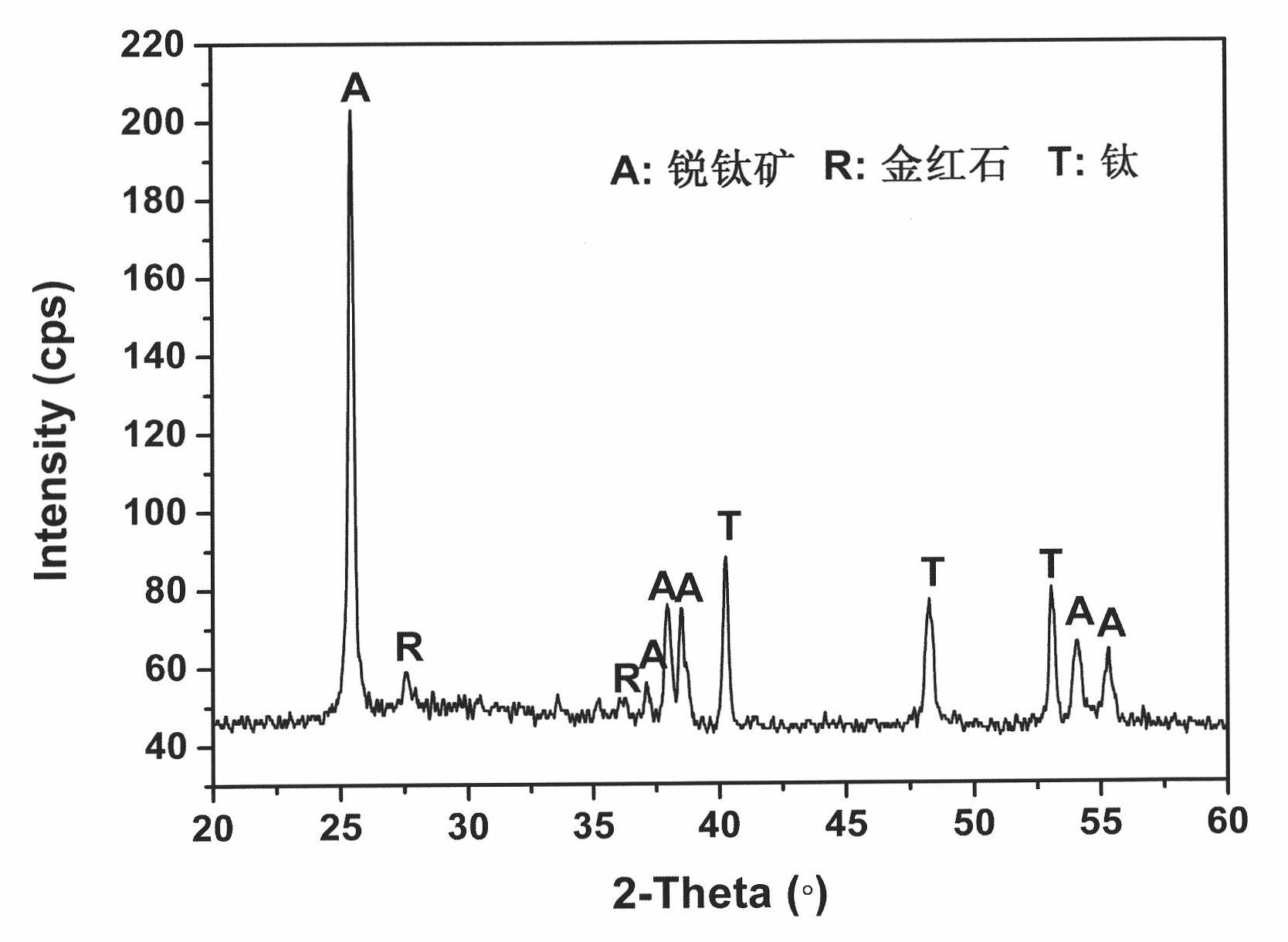

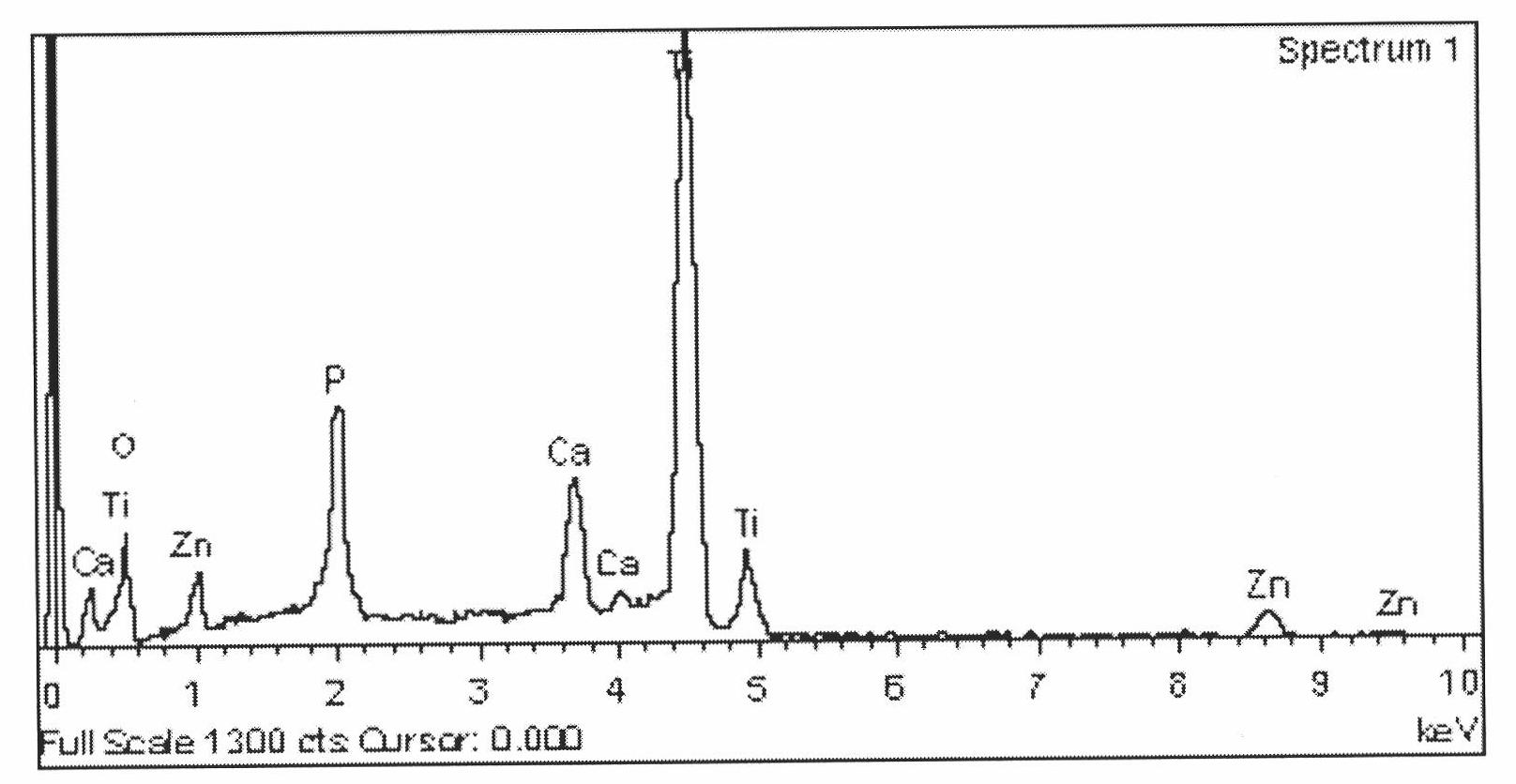

[0029] (a) Using deionized water, mix 0.02 mol / L zinc acetate, 0.1 mol / L calcium acetate and 0.05 mol / L sodium glycerophosphate to prepare an electrolyte solution. (b) With titanium as the anode and stainless steel as the cathode, a DC pulse power supply is used at a constant current density of 0.5A / cm 2 , Voltage 400-460V, frequency 800Hz, duty cycle 10% under the conditions of treatment for 4min, keep the electrolyte temperature below 60 ℃. (c) After the sample was taken out, it was rinsed in deionized water and dried naturally. After testing, the thickness of the coating is about 5-10 μm, and the element composition is mainly Ti, O, Zn, Ca and P. X-ray diffraction analysis shows that the coating phase composition is mainly pure anatase TiO 2 , EDS results show that the zinc content in the coating is about 3.4wt%, and SEM analysis shows that the pore size of the coating is less than 10 μm, and the grain size is 10-100nm.

Embodiment 2

[0031] (a) Using deionized water, mix 0.04 mol / L zinc acetate, 0.1 mol / L calcium acetate and 0.05 mol / L sodium glycerophosphate to prepare an electrolyte solution. (b) With titanium as the anode and stainless steel as the cathode, a DC pulse power supply is used at a constant current density of 0.5A / cm 2 , Voltage 400-480V, frequency 800Hz, duty cycle 10% under the conditions of treatment for 4min, keep the electrolyte temperature below 60 ℃. (c) After the sample was taken out, it was rinsed in deionized water and dried naturally. After testing, the thickness of the coating is about 6-12 μm, and the element composition is mainly Ti, O, Zn, Ca and P. X-ray diffraction analysis shows that the coating phase composition is mainly anatase TiO 2 and rutile TiO 2 , EDS results show that the content of zinc in the coating is about 7.3wt%, and SEM analysis shows that the pore size of the coating is less than 10 μm, and the grain size is 20-100nm.

Embodiment 3

[0033] (a) Using deionized water, mix 0.08 mol / L zinc nitrate, 0.2 mol / L calcium acetate, 0.02 mol / L sodium glycerophosphate and 0.1 mol / L sodium hydroxide to prepare an electrolyte solution. (b) With titanium as the anode and stainless steel as the cathode, a DC pulse power supply is used at a constant current density of 1A / cm 2 , The voltage is 500-600V, the frequency is 1000Hz, and the duty cycle is 30% for 3 minutes, and the temperature of the electrolyte is kept below 60°C. (c) After the sample was taken out, it was rinsed in deionized water and dried naturally. After testing, the thickness of the coating is about 25-35 μm, and the element composition is mainly Ti, O, Zn, Ca and P. X-ray diffraction analysis shows that the coating phase composition is mainly anatase TiO 2 and rutile TiO 2 , EDS results show that the zinc content in the coating is about 15.7wt%, and SEM analysis shows that the pore size of the coating is less than 20 μm, and the grain size is 40-100nm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com