Gamma-aminobutyric acid-containing milk beverage and production method thereof

A technology of milk beverage and yogurt, which is applied in the field of milk beverage containing γ-aminobutyric acid and its production, to achieve the effects of delicate taste, expanded sales range, and uniform organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Formula (according to 1 ton):

[0043] Skim milk powder 4.0 kg whey powder 4.0 kg white sugar 60.0 kg monoglyceride 0.6 kg soybean polysaccharide 1.99 kg pectin 0.4 kg gamma-aminobutyric acid 0.2 kg peach juice 40.0 kg lactic acid 1.3 kg citric acid 2.0 kg essence 1.8 kg purified water 863.71 kilograms.

[0044] Raw material standard:

[0045] Milk: protein ≥ 2.95% fat ≥ 3.3% non-fat milk solids ≥ 8.5%

[0046] White granulated sugar: in line with the national first-class standard.

[0047] High fructose syrup: F≥42.0%.

[0048] Grape Juice:

[0049] grape puree;

[0050] Pulp system pH3.7;

[0051] Brix 35BX.

[0052] Purified water, lactic acid, citric acid: in line with national standards.

[0053] The preparation process of gamma-aminobutyric acid milk beverage of the present invention is as follows:

[0054] 1) Preparation of syrup: add white granulated sugar, sweetener, etc. into an appropriate amount of pure water, stir and dissolve, filter, sterilize, a...

Embodiment 2

[0068] Formula (according to 1 ton):

[0069] Milk 370.0 kg white sugar 30.0 kg fructose syrup 53.0 kg xanthan gum 0.8 kg pectin 0.58 kg mono-diglycerides 0.3 kg guar gum 0.8 kg vitamin A 0.9 kg vitamin D 0.02 kg calcium lactate 3.3 kg gamma-aminobutyric acid 20 Kg Malic Acid 1.1 Kg Citric Acid 2.3 Kg Essence 1.64 Kg Purified Water 515.26 Kg.

[0070] Raw material standard:

[0071] Milk: protein ≥ 2.95% fat ≥ 3.3% non-fat milk solids ≥ 8.5%

[0072] White granulated sugar: in line with the national first-class standard.

[0073] High fructose syrup: F≥42.0%.

[0074] Vitamin A, D, calcium: in line with national standards.

[0075] Purified water, malic acid, citric acid: in line with national standards.

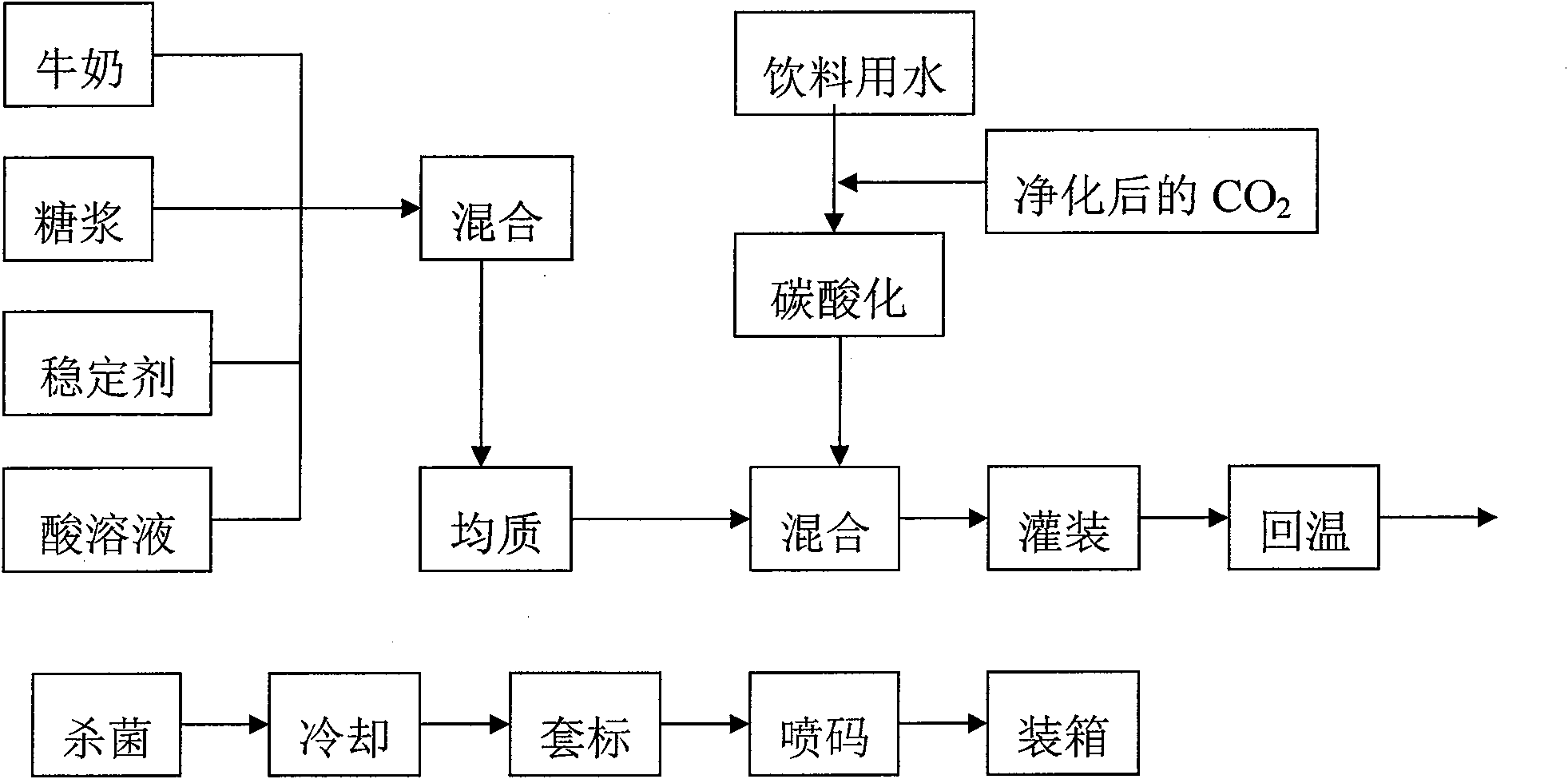

[0076] The gamma-aminobutyric acid beverage of the present invention presses figure 1 The shown process route is produced, and the preparation process is as follows:

[0077] 1) Pour cold milk at 6°C into the ingredients tank.

[0078] 2) Dissolution of the stabilize...

Embodiment 3

[0091] Formula (according to 1 ton):

[0092] Milk 500.0 kg White sugar 55.0 kg Aspartame 0.07 kg Glycerin fatty acid ester 0.3 kg Gellan gum 0.9 kg Pectin 2.4 kg Carboxymethyl cellulose sodium 1.5 kg γ-aminobutyric acid 5.7 kg Phosphoric acid 1.7 kg Lactic acid 2.0 kg Flavor 0.67 One kilogram of pure water is 429.76 kilograms.

[0093] Raw material standard:

[0094] Milk: protein ≥ 2.95% fat ≥ 3.3% non-fat milk solids ≥ 8.5%

[0095] White granulated sugar: meets the first-class standard of Weijia.

[0096] High fructose syrup: F≥42.0%.

[0097] Purified water, phosphoric acid, citric acid: in line with national standards.

[0098] The gamma-aminobutyric acid beverage of the present invention presses figure 1 The shown process route is produced, and the preparation process is as follows:

[0099] 1) Pour cold milk at 6°C into the ingredients tank.

[0100] 2) Dissolution of the stabilizer: Mix the stabilizer and white sugar evenly, take an appropriate amount of pure w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com