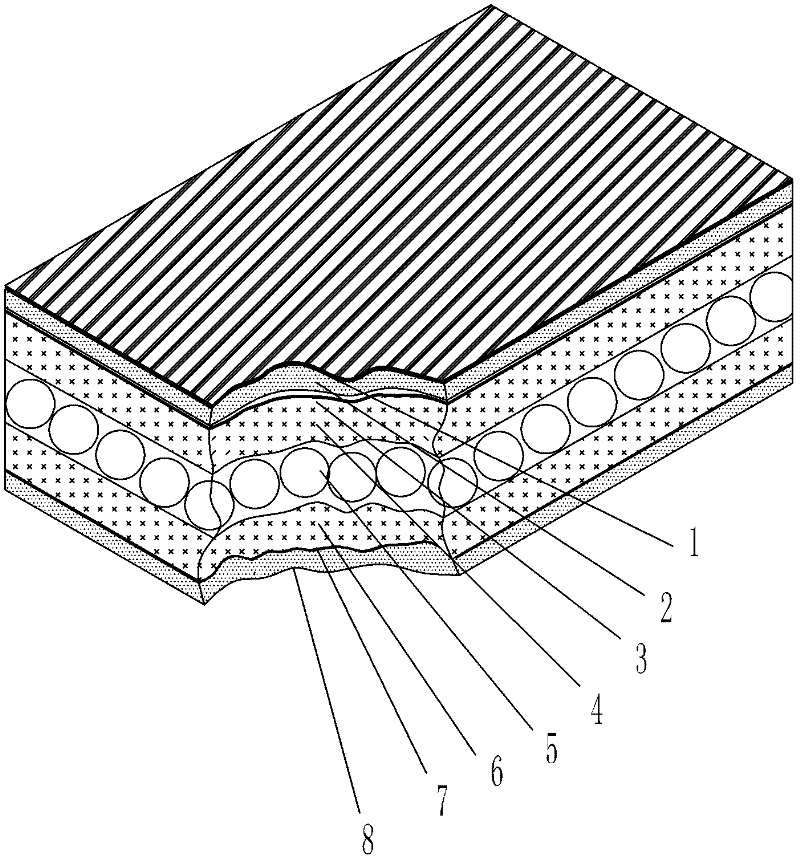

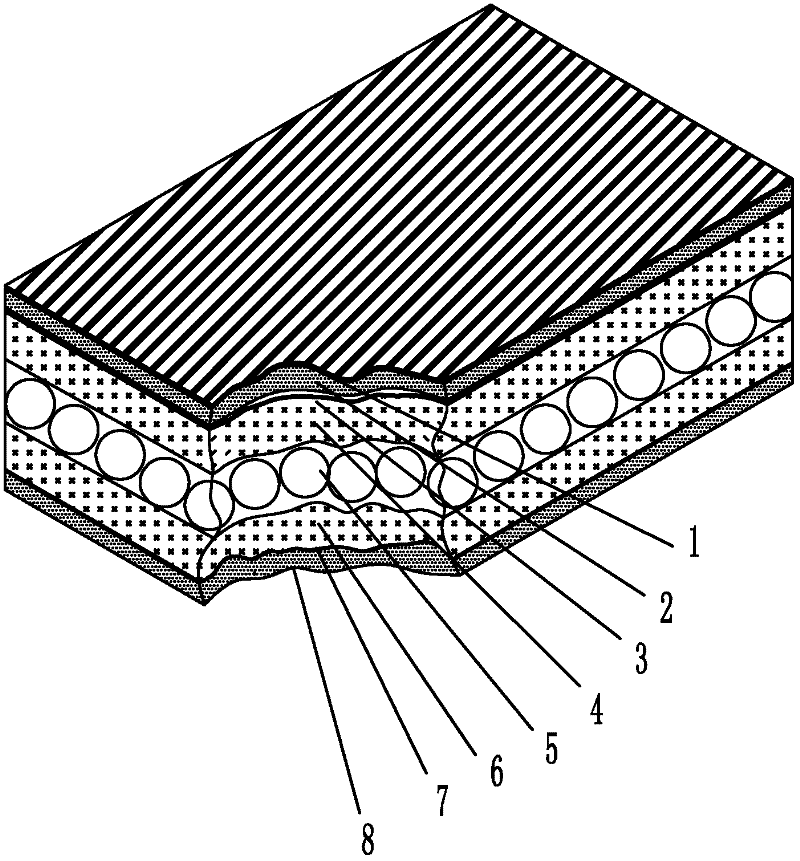

Low-carbon fireproof thermal insulation decoration board with vacuum vesicle structure and preparation method for board

A technology of fire prevention and heat preservation and vacuum bag, which is applied in the field of building decoration boards, can solve the problems of poor durability, easy cracking, and easy falling off, and achieve the effects of reducing ecological environment damage, good heat preservation performance and decoration, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] Taking rock wool fiber as an example to briefly describe the preparation method of vacuum capsules:

[0070] 1. Preparation of filling core material: select rock wool fibers with a diameter of 3-5 μm, mince them, and dry them at a constant temperature of 120°C until they reach a constant weight. 2. Preparation of vacuum barrier film bags: multi-layer composite films are prepared by extrusion molding and vacuum packaging bags of different sizes are prepared by blow molding. 3. Preparation of rock wool-filled pipes: PET, PVC or other polymer material pipes are used as the For the foundation, select a square tube with a length of 50-100 cm, a wall thickness of 1-5 mm, and a side length of 10-50 mm, and fill the rock wool fiber prepared in step 1 into the square tube for compaction. 4. Preparation of truncation: adopt mechanical cutting means, cut into small pieces with a length of 1-30mm according to the designed size, and then dry at 70°C to constant weight. 5. Preparati...

Embodiment 1

[0072] Inorganic mineral tailings surface layer of low-carbon fireproof, thermal insulation and decorative integrated board, by weight, 1Kg / part

[0073] Aluminum magnesium silicate powder 10 Kg, lightly burned magnesium powder 1 Kg, magnesium cementitious material regulator 1 Kg,

[0074] Silica fume powder 1 Kg, phosphoric acid or sulfate powder 10 Kg, ore tailings 70 Kg,

[0075] 1 Kg of mineral sand or colored quartz sand, 1 Kg of iron oxide ore powder, 1 Kg of mineral wool fiber,

[0076] Reinforced glass fiber 30 Kg, polypropylene fiber 1 Kg.

[0077] The inorganic-organic composite thermal insulation wrapping layer, in parts by weight, 1Kg / part comprises:

[0078] Aluminum magnesium silicate powder 10 Kg, lightly burned magnesium powder 1 Kg, silica fume powder 20 Kg,

[0079] Magnesia cementitious material regulator 50 Kg, phosphoric acid or sulfate powder 1 Kg, ore tailing powder 1 Kg, ore sand or colored quartz sand 1 Kg, iron oxide ore powder 20 Kg, mineral wool ...

Embodiment 2

[0081] Inorganic mineral tailings surface layer of low-carbon fireproof, thermal insulation and decorative integrated board, by weight, 1Kg / part

[0082] 50 Kg of aluminum magnesium silicate powder, 50 Kg of lightly burned magnesium powder, 50 Kg of magnesium cementitious material regulator,

[0083] Silica fume powder 20 Kg, phosphoric acid or sulfate powder 1 Kg, ore tailings 1 Kg,

[0084] Mineral sand or colored quartz sand 1-70, iron oxide ore powder 1 Kg, mineral wool fiber 30 Kg,

[0085] Reinforced glass fiber 1 Kg, polypropylene fiber 30 Kg.

[0086] The inorganic-organic composite thermal insulation wrapping layer, in parts by weight, 1Kg / part

[0087] Aluminum magnesium silicate powder 50 Kg, lightly burned magnesium powder 50 Kg, silica fume powder 1-20,

[0088] Magnesium cementitious material regulator 1 Kg, phosphoric acid or sulfate powder 10 Kg, ore tailing powder 70 Kg, ore sand or colored quartz sand 70 Kg, iron oxide ore powder 1 Kg, mineral wool fiber 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com