Preparation method of alkyl transferring catalyst

A technology of transalkylation and catalyst, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low transalkylation performance, low benzene/propylene ratio, low reaction temperature, etc., and achieve total Strong acidity, high activity, good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take by weighing 200g of the former powder of HMCM-49 molecular sieve produced by Jilin University, 100g of imported SB powder, 10g of kale powder, and 10g of methyl cellulose and mix them with 200g of 15% aqueous nitric acid solution. After granulation and extrusion, the extrusion pressure is 150N, the wet strips are placed on the enamel plate, and dried at 120°C for 5.6h; after drying, they are transferred to the roasting pan and roasted in the muffle furnace, and the roasting temperature is programmed. The stepwise temperature was 120°C, 450°C and 540°C, the heating rate was 1°C / min, and the catalyst was calcined at 540°C for 320 minutes to prepare the catalyst.

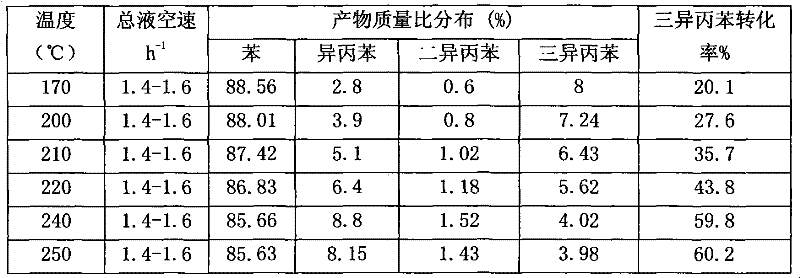

[0026] Put the catalyst into the tubular reactor, the reactor is Φ25*2*900mm, and carry out the reaction of triisopropylbenzene and benzene, the mass percentage of triisopropylbenzene and benzene is 90:10, and the total liquid space velocity is 1.4-1.6h -1 , the reaction temperature is 170-250°C, and the re...

Embodiment 2

[0030] Take by weighing 180g of the former powder of HMCM-22 molecular sieve produced by Jilin University, 90g of imported SB powder, 16g of ammonium phosphate, 8g of scallop powder, and 7g of citric acid. 190g, mix evenly; roll on the rolling machine for 25min, after granulation and extruding, extruding pressure 150N, place the wet strip on the enamel plate, dry at 110°C for 5.2h; after drying, move to the baking tray In this method, the catalyst was calcined in a muffle furnace, the calcining temperature was programmed to rise, the stepwise temperature was 120°C, 450°C and 540°C, the heating rate was 2°C / min, and the catalyst was calcined at 540°C for 7.3h.

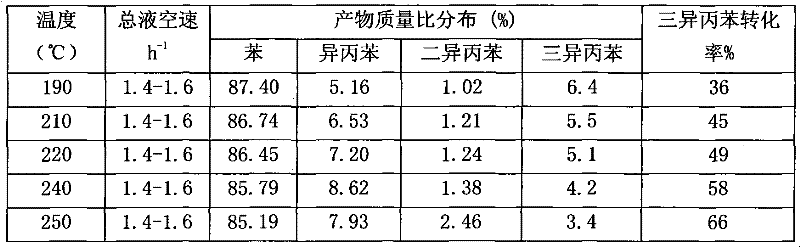

[0031] Using the evaluation method of Example 1, the reaction results are shown in Table 2.

[0032] Table II

[0033]

Embodiment 3

[0035] Weigh 100g of HMCM-49 molecular sieve raw powder produced by Jilin University, 100g of HMCM-22 molecular sieve raw powder, 95g of imported SB powder, 6.3g of turnip powder, 8.5g of citric acid, add 180g of 10% phosphoric acid aqueous solution and mix evenly, Roll on the press for 30 minutes, granulate, extrude, extrusion pressure 150N, put the wet strip on the enamel plate, dry at 115°C for 5.7h; The calcination temperature was programmed to raise the temperature, the subsection temperature was 120°C, 450°C and 540°C, the heating rate was 2°C / min, and the catalyst was calcined at 540°C for 10 hours to prepare the catalyst.

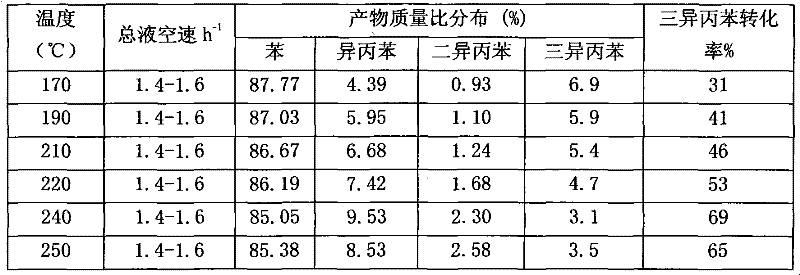

[0036] Using the evaluation method of Example 1, the reaction results are shown in Table 3.

[0037] Table three

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com