Lithium ion battery electrode material coated with non-continuous graphene

A graphene-coated, lithium-ion battery technology, applied to battery electrodes, circuits, electrical components, etc., can solve the problems that restrict the development of lithium iron phosphate, slow diffusion of lithium ions, and complex surface structures, etc., to achieve large-scale The effects of industrial production and application, good lithium ion mobility, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

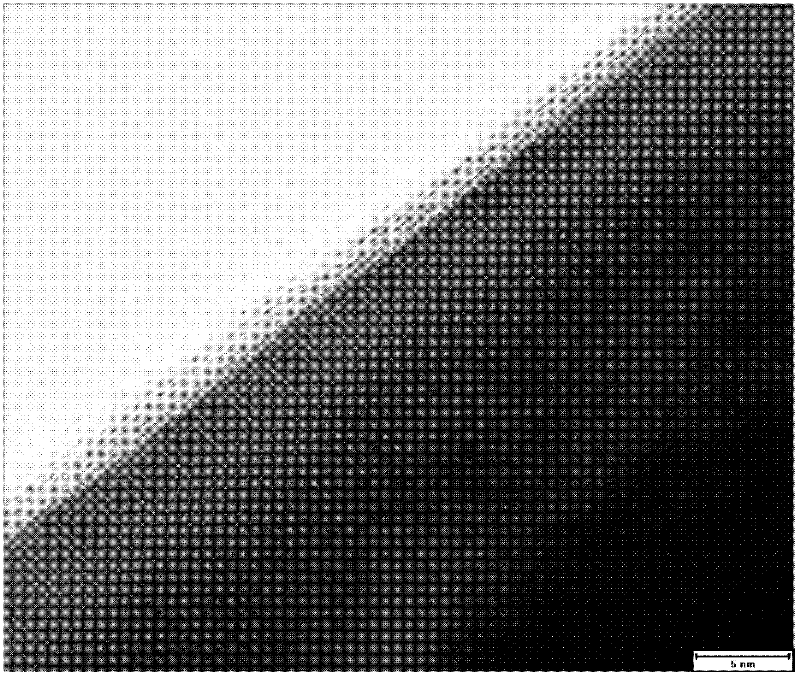

[0032] Disclosed is a discontinuous graphene-coated lithium ion battery electrode material, wherein the electrode material is lithium iron phosphate particles, a positive electrode material, and the coated graphene is discontinuously and tightly attached to the surface of the lithium iron phosphate particles. The area covered by graphene accounts for 99% of the total surface area of the lithium iron phosphate particles. The mass ratio of discontinuous graphene to lithium iron phosphate particles is 5%.

[0033] In this implementation, the lithium iron phosphate particles coated with discontinuous graphene are prepared according to the following steps:

[0034] Lithium iron phosphate particles are sintered in an atmosphere furnace, methanol, water vapor, and inert gas nitrogen and argon are introduced at the same time, and the volume fractions of methanol and water vapor introduced are 40% and 10% respectively, and the atmosphere is controlled. The temperature in the furnace...

Embodiment 2

[0037] A discontinuous graphene-coated lithium ion battery electrode material, wherein the electrode material is lithium nickelate particles, which are positive electrode materials, and the coated graphene is discontinuously and closely attached to the surface of the lithium nickelate particles. The coated graphene is multilayer graphene with 4-8 layers. The area covered by graphene accounts for 99% of the total surface area of lithium nickelate particles. The mass ratio of discontinuous graphene to lithium nickelate particles is 10%.

[0038] Its preparation method is the same as in Example 1, the only difference is that the electrode material is lithium nickelate particles, and the volume fractions of methanol and water vapor introduced are respectively 90% and 0.1%, the inert gas is nitrogen, and the temperature in the atmosphere furnace is controlled 500°C, and reacted for 40 hours.

Embodiment 3

[0040]A discontinuous graphene-coated lithium-ion battery electrode material, wherein the electrode material is lithium iron manganese phosphate particles of positive electrode material, and the coated graphene is discontinuously and tightly attached to the surface of the lithium iron manganese phosphate particles. The coated graphene is multilayer graphene with 2-6 layers. The area covered by graphene accounts for 30% of the total surface area of the lithium iron manganese phosphate particles. The mass ratio of discontinuous graphene to lithium iron manganese phosphate particles is 0.2%. Its preparation method is the same as in Example 1, the only difference is that the electrode material is lithium iron manganese phosphate particles, and the volume fractions of ethyl acetate and water vapor introduced are 1% and 15% respectively, the inert gas is argon, and the atmosphere is controlled The temperature in the furnace was 1300°C, and the reaction was carried out for 3 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com