Micro/nano interface separation net as well as preparation method and application thereof

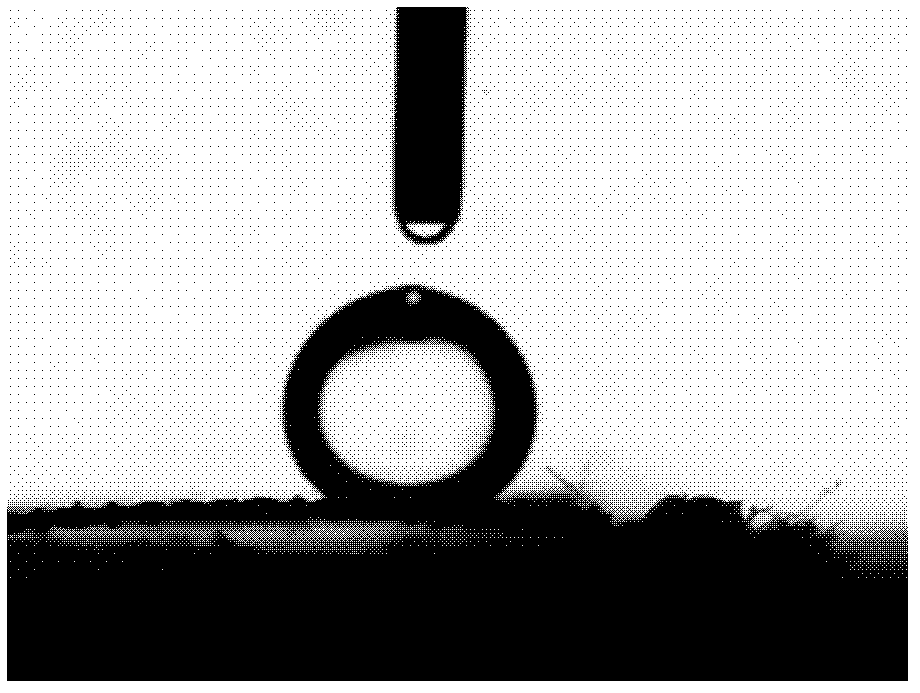

A separation net and nano technology, which is applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of difficulty in ensuring the uniformity of the coating on the surface of the separation net, single function of the oil-water separation net, and failure to achieve oil-water separation. , to achieve the effect of good redox reversibility, easy and precise control, and diversified functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing the above-mentioned micro / nano interface separation network, which specifically includes the following steps:

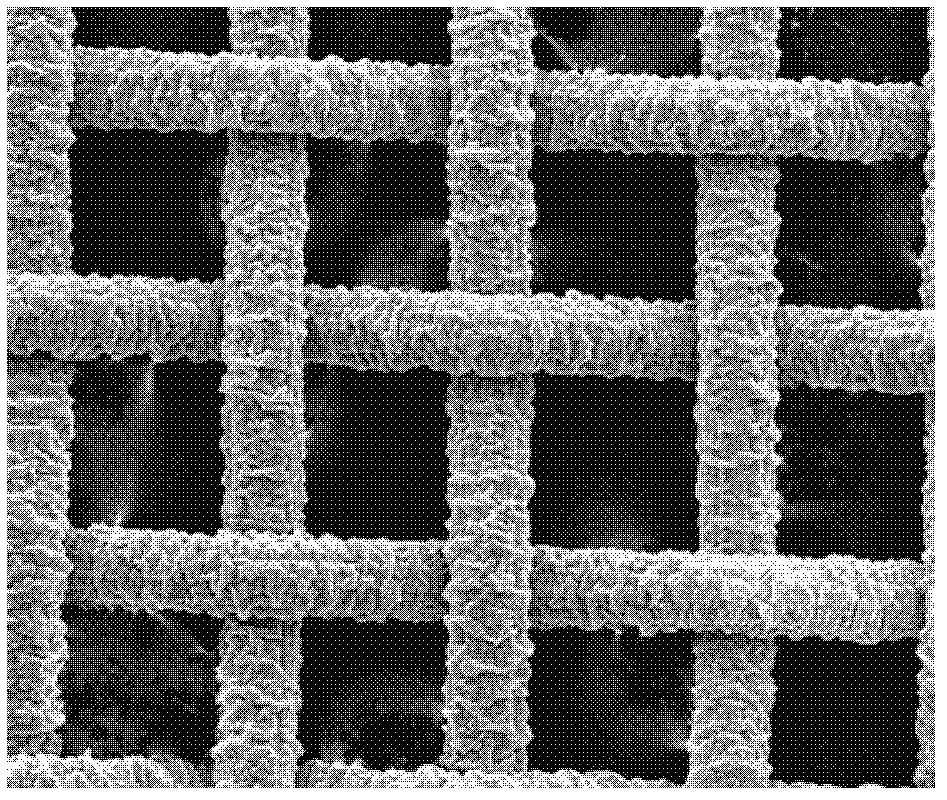

[0037] (1) Alternately immerse the 40-300 mesh metal fiber braided net in absolute ethanol and deionized water for ultrasonic cleaning, and finally dry it at normal temperature;

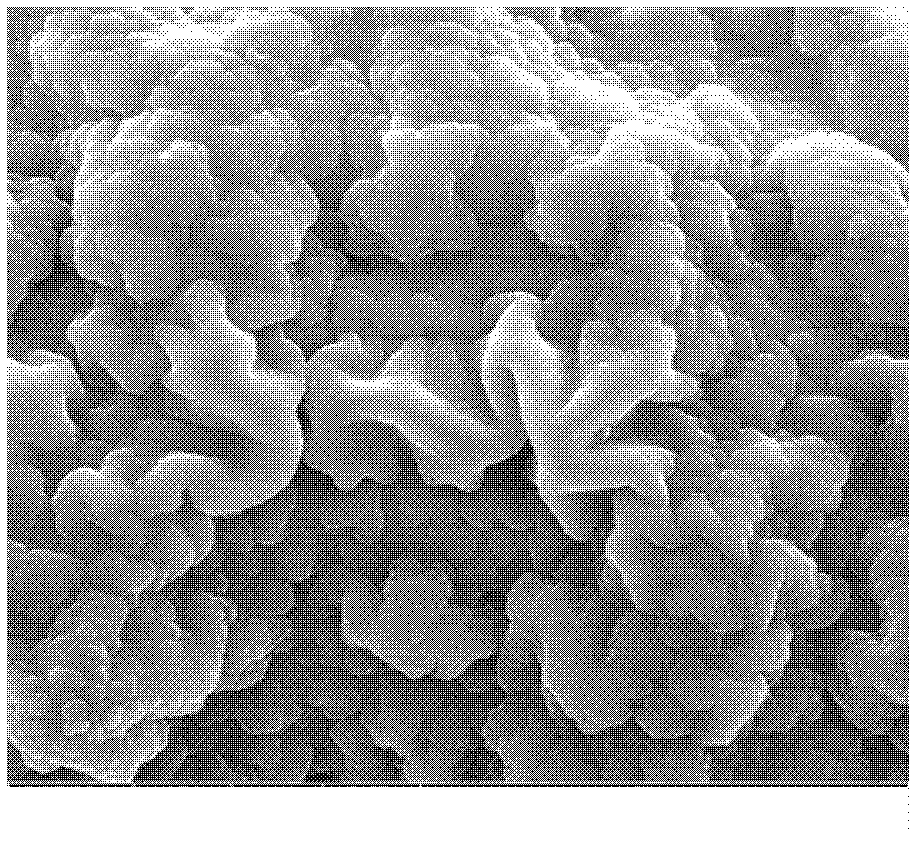

[0038] (2) Prepare an electrolyte solution containing a dopant / conductive polymer monomer, which specifically consists of 0.01-1 parts by weight of a conductive polymer monomer, 0.02-2 parts by weight of a dopant and 10 parts by weight of distilled water composition, ultrasonically disperse the electrolyte into an emulsion;

[0039] (3) immerse the metal fiber braided mesh, platinum sheet, and silver-silver chloride electrode in the above-mentioned emulsion, wherein the metal fiber braided mesh is the working electrode, the platinum sheet is the auxiliary electrode, and the silver-silver chloride electrode is the reference el...

Embodiment 1

[0045] (1) 40-mesh stainless steel fiber braided mesh (2.5cm×1cm) was alternately immersed in absolute ethanol and deionized water for ultrasonic cleaning, and finally dried at room temperature;

[0046] (2) prepare the electrolytic solution containing dopant / conducting polymer monomer, this electrolytic solution is specifically made of 0.01 gram of 3,4-ethylenedioxythiophene, 0.05 gram of sodium lauryl sulfate and 10 grams of distilled water composition, ultrasonically disperse the electrolyte into an emulsion;

[0047] (3) Immerse the stainless steel fiber braided mesh, smooth platinum sheet (2cm×1cm), and silver-silver chloride electrode (electrolyte concentration is 3M) in the emulsion of step 2, wherein the stainless steel fiber braided mesh is the working electrode, and the platinum sheet As the auxiliary electrode, the silver-silver chloride electrode is used as the reference electrode, forming a three-electrode system, controlling the constant potential at 1.6V, and re...

Embodiment 2

[0050] (1) 100-mesh stainless steel fiber woven mesh (2.5cm×1cm) was alternately immersed in absolute ethanol and deionized water for ultrasonic cleaning, and finally dried at room temperature;

[0051] (2) prepare the electrolytic solution containing dopant / conductive polymer monomer, this electrolytic solution is specifically made up of 3-hexylthiophene of 0.05 gram, the sodium dodecylbenzenesulfonate of 0.5 gram and the distilled water of 10 gram, will The electrolyte is ultrasonically dispersed into an emulsion;

[0052] (3) Immerse the stainless steel fiber braided mesh, smooth platinum sheet (2cm×1cm), and silver-silver chloride electrode (electrolyte concentration is 3M) in the emulsion of step 2, wherein the stainless steel fiber braided mesh is the working electrode, and the platinum sheet As the auxiliary electrode, the silver-silver chloride electrode is used as the reference electrode, forming a three-electrode system, controlling the constant potential at 1.4V, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com