Epoxy floor coating containing epoxy polyether organosilicon hybrid and preparation method thereof

An epoxy-based polyether and epoxy floor technology, applied in epoxy resin coatings, coatings and other directions, can solve the problems of ineffective toughening effect, reduce the heat resistance of epoxy resin, etc., to solve the problem of easy scratching Injury, increase binding force, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

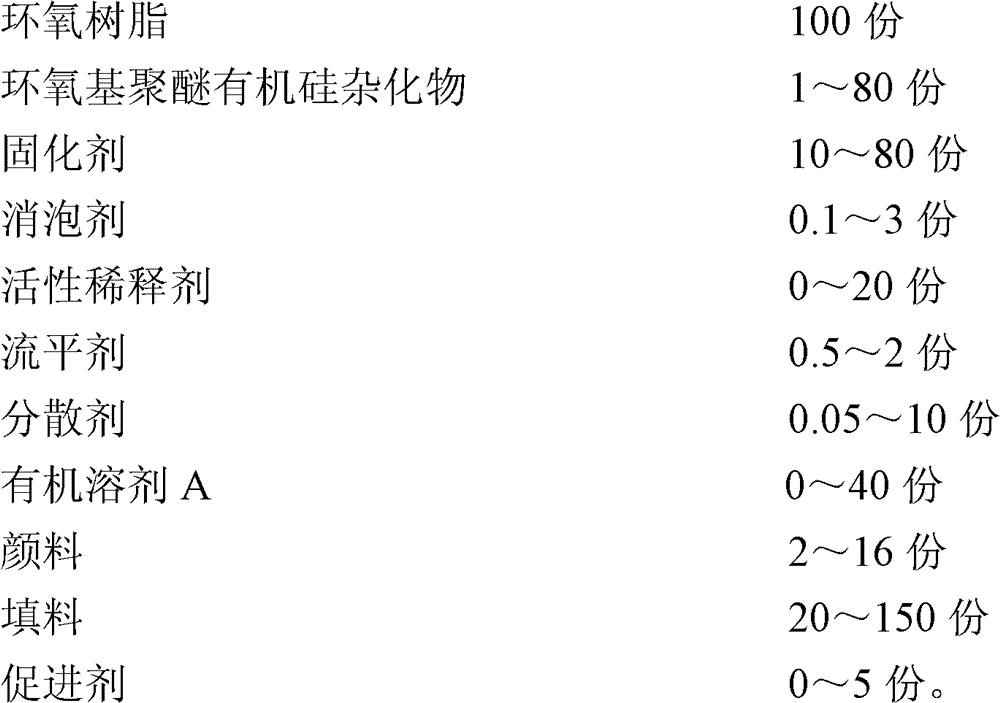

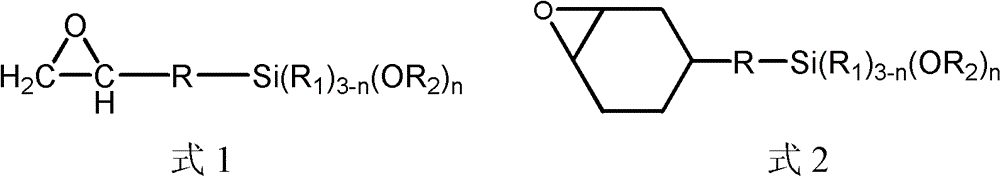

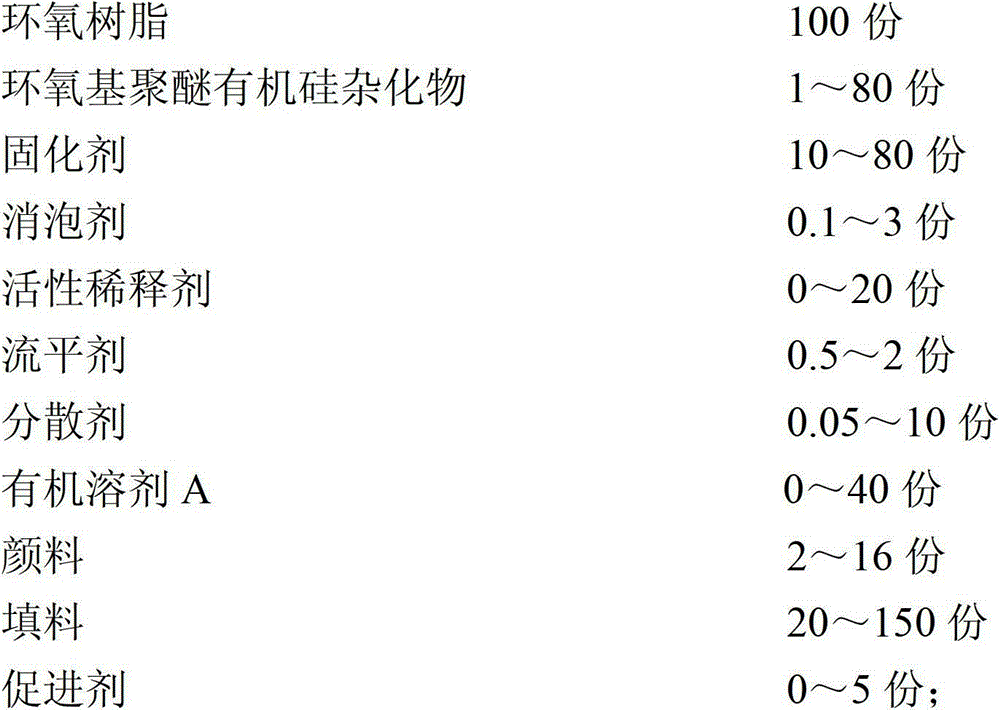

Method used

Image

Examples

Embodiment 1

[0037](1) 25g dimethyldimethoxysilane, 75g methyltriacetoxysilane, 3g 4-(1,2-epoxyethyl) butyltrimethoxysilane (X-12-699), 100g of tetrahydrofuran, 10g of deionized water and 0.5g of dibutyltin dilaurate were mixed uniformly, then hydrolyzed and polycondensed at 65°C for 5 hours, and then added with 500g of polyethylene glycol monomethyl ether (molecular weight: 600), 500g of tetrahydrofuran and 10g of dilauric acid After the dibutyltin is mixed evenly, react at 65°C for 8 hours, and distill under reduced pressure to remove small molecular substances such as tetrahydrofuran and water to obtain the epoxy polyether organosilicon hybrid.

[0038] (2) 100g of bisphenol A type epoxy resin (E-51), 0.1g of defoamer BYK066 (manufactured by German BYK company), 10g of propylene oxide butyl ether, 0.8g of leveling agent EFKA3777, dispersant BYK- 0.05g of P104 (produced by German BYK company), 16g of titanium dioxide, 20g of kaolin, 20g of epoxy polyether organosilicon hybrid synthesized...

Embodiment 2

[0043] (1) 50g of diphenylsilanediol, 20g of tetraethoxysilane, 30g of methyltrimethoxysilane, 50g of 8-(1,2-epoxyethyl)octyltrimethoxysilane (X-12- 692), 150g of ethanol, 25g of deionized water and 1.5g of dibutyltin diacetate were mixed uniformly, then hydrolyzed and polycondensed at 78°C for 6 hours, and then 300g of monoepoxide-terminated hydroxyl polyether (molecular weight 1000, ring The mass ratio of ethylene oxide to propylene oxide structural units is 3 / 1), 300g ethanol and 3g dibutyltin diacetate, mix well, react at 78°C for 8h, and distill under reduced pressure to remove small molecular substances such as ethanol and water , That is, epoxy-based polyether silicone hybrids.

[0044] (2) 100g of bisphenol A type epoxy resin (E-44), 0.8g of defoamer BYK066 (produced by BYK Company in Germany), 5g of C12-C14 fatty alcohol glycidyl ether, 1.6g of leveling agent EFKA3777, and dispersant BYK163 (produced by German BYK company) 8g, carbon black 10g, talcum powder 150g, ep...

Embodiment 3

[0046] (1) Mix 50g methyltrichlorosilane, 50g dimethyldimethoxysilane, 30g 3-(2,3-epoxypropoxy)propylmethyldimethoxysilane, 50g tetrahydrofuran, 5g deionized Water and 2g of dibutyltin diacetate were mixed evenly, and then hydrolyzed and polycondensed at 50°C for 10 hours, then 100g of polyethylene glycol with a molecular weight of 1000, 100g of tetrahydrofuran, and 1g of dibutyltin diacetate were added, and mixed evenly, at 50 React at ℃ for 10h, mix well and react at 50℃ for 10h, distill under reduced pressure to remove small molecular substances such as tetrahydrofuran and water, and obtain epoxy polyether organosilicon hybrid.

[0047] (2) Bisphenol A type epoxy resin E-54 100g, polysiloxane defoamer BYK066 (produced by BYK Germany) 1.2g, butanol 10g, leveling agent EFKA37770.5g, dispersant BYK163 (BYK Germany) Produced by the company) 10g, chrome yellow 2g, quartz sand 40g, epoxy-based polyether organosilicon hybrid 40g synthesized in step (1), placed in a strong mixer an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com