High-glossiness flame-retardant polypropylene composite and preparation method thereof

A technology of flame-retardant polypropylene and composite materials, which is applied in the field of high-gloss flame-retardant polypropylene composite materials and its preparation, can solve the problems of low flame-retardant efficiency, large addition amount, and secondary pollution of halogen-free flame-retardant technology, and achieve Low toxicity, low smoke production and low smoke density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

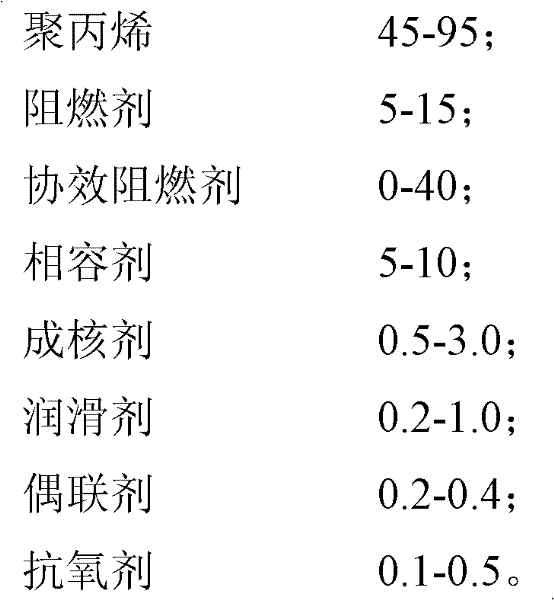

Method used

Image

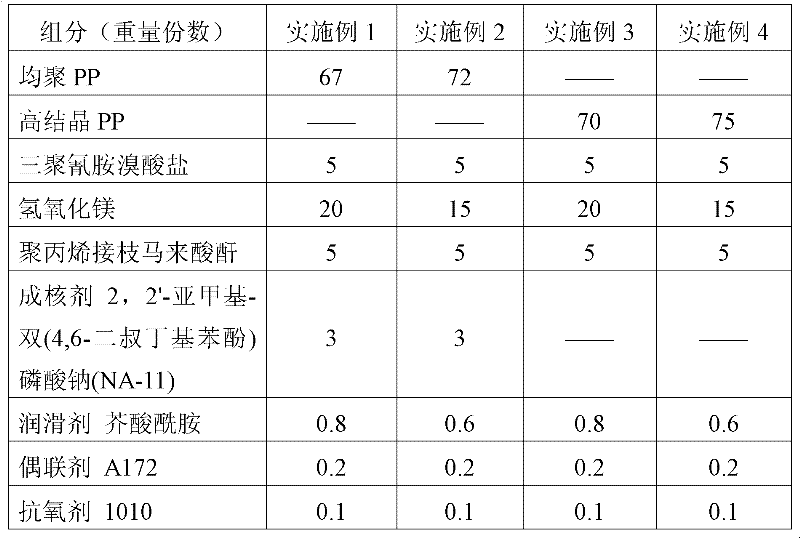

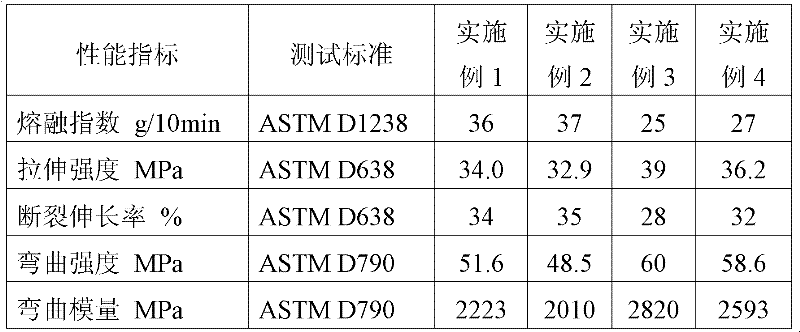

Examples

Embodiment 5

[0034] A high-gloss flame-retardant polypropylene composite material, comprising the following components in parts by weight: homopolypropylene 45 with a melt index of 10g / 10min; the flame retardant is melamine bromate 15; the synergistic flame retardant is granular Magnesium hydroxide 40 with a diameter of 0.5 microns; the compatibilizer is polypropylene grafted maleic anhydride 10 with a grafting rate of 6%; the nucleating agent of sorbitol derivatives 3.0; the lubricant is solid paraffin 1.0; Joint agent 0.4; antioxidant 1010 0.5.

[0035] The above-mentioned components are weighed according to the proportion and mixed evenly; then the mixture is put into a twin-screw extruder for melt extrusion, strand drawing, cooling, pelletizing, and drying to obtain a high-gloss flame-retardant polypropylene composite material; Wherein, the aspect ratio of the twin-screw extruder is 32:1, the processing temperature is 220° C., and the screw speed is 350 rpm.

Embodiment 6

[0037] A high-gloss flame-retardant polypropylene composite material, comprising the following components in parts by weight: high crystallization polypropylene 95 with a melt index of 60g / 10min; the flame retardant is melamine bromate 5; the compatibilizer is grafting rate 0.5% polypropylene graft maleic anhydride 5; rosin acid nucleating agent 0.5; low molecular weight polyethylene wax 0.2 lubricant; titanate coupling agent 0.2; antioxidant 1680.1.

[0038] The above-mentioned components are weighed according to the proportion and mixed evenly; then the mixture is put into a twin-screw extruder for melt extrusion, strand drawing, cooling, pelletizing, and drying to obtain a high-gloss flame-retardant polypropylene composite material; Wherein, the aspect ratio of the twin-screw extruder is 40:1, the processing temperature is 170° C., and the screw speed is 450 rpm.

Embodiment 7

[0040] A high gloss flame retardant polypropylene composite material, comprising the following components in parts by weight: a homopolypropylene 50 with a melt index of 35g / 10min, a high crystalline polypropylene 30 with a melt index of 45g / 10min; the flame retardant is Melamine bromate 12; the synergistic flame retardant is magnesium hydroxide 30 with a particle size of 1-2 microns; the compatibilizer is polypropylene grafted maleic anhydride 8 with a grafting ratio of 3.5%; organic carboxylic acid and carboxylic acid Salt nucleating agent 1.5; lubricant calcium stearate 0.2, zinc stearate 0.2, EBS 0.1; titanate coupling agent 0.2, aluminate coupling agent 0.1; antioxidant 1010 0.2, antioxidant Agent 168 0.1.

[0041] The above-mentioned components are weighed according to the proportion and mixed evenly; then the mixture is put into a twin-screw extruder for melt extrusion, strand drawing, cooling, pelletizing, and drying to obtain a high-gloss flame-retardant polypropylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com