Application of photocatalyst of TiO2 (titanium dioxide) loaded on glass fiber fabric to treating microcystin

The technology of glass fiber cloth and microcystin is applied in the fields of environmental pollution control and water treatment technology, which can solve the problems of insufficient effective oxidizing ability, limitation of popularization and application, low utilization rate of ozone, etc., and achieves good application transformation prospects, light transmission Good performance and improved photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

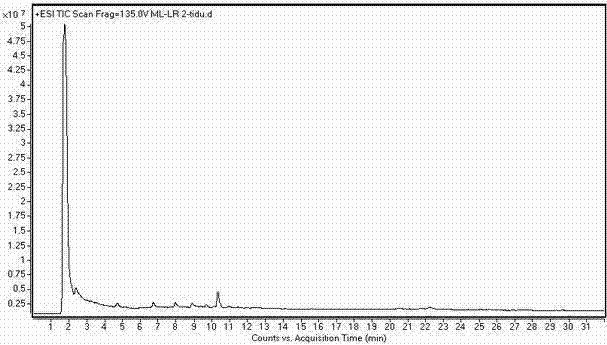

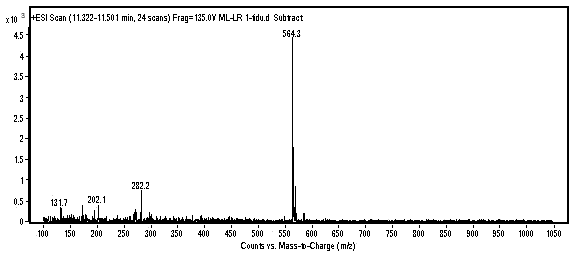

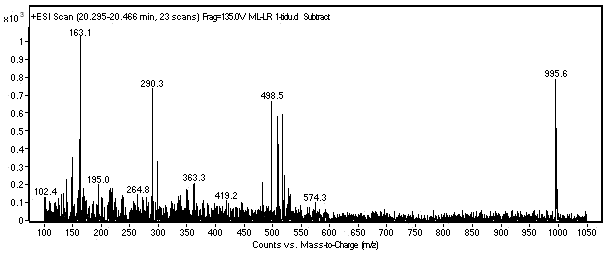

Image

Examples

Embodiment 1

[0023] This kind of photocatalyst used in the treatment of microcystins is realized according to the following steps:

[0024] 1) TiO 2 Sol preparation:

[0025] The TiO 2 Preparation of sol: Dissolve 85mL tetrabutyl titanate in 400mL absolute ethanol, add 15mL hydrolysis inhibitor triethanolamine, stir magnetically for 1.5h to make A solution; mix 9mL deionized water and 50mL absolute ethanol, add nitric acid Adjust the pH to 3.0 to make B solution. Slowly add solution B to solution A with magnetic stirring, and continue to stir for 1 hour after the addition is completed to obtain a yellowish transparent sol; the sol is sealed and aged in a dark place for 24 hours for later use; the ratio of each raw material is: n (Cl 2 h 36 o 4 Ti): n (C 4 h 11 NO 2 ) : n (C 2 h 5 OH): n (H 2 (0)=1:0.86:26.6:2.

[0026] 2) Glass fiber cloth loaded TiO 2 :

[0027] The glass fiber cloth loaded with TiO 2 Follow the steps below: a. Soak a glass fiber cloth with a length o...

Embodiment 2

[0029] This kind of photocatalyst used in the treatment of microcystins is realized according to the following steps:

[0030] 1) TiO 2 Sol preparation:

[0031] The TiO 2 Preparation of sol: Dissolve 85mL tetrabutyl titanate in 400mL absolute ethanol, add 15mL hydrolysis inhibitor triethanolamine, stir magnetically for 1.5h to make A solution; mix 9mL deionized water and 50mL absolute ethanol, add nitric acid Adjust the pH to 3.0 to make B solution. Slowly add solution B to solution A with magnetic stirring, and continue to stir for 1 hour after the addition is completed to obtain a yellowish transparent sol; the sol is sealed and aged in a dark place for 24 hours for later use; the ratio of each raw material is: n (Cl 2 h 36 o 4 Ti): n (C 4 h 11 NO 2 ) : n (C 2 h 5 OH): n (H 2 (0)=1:0.86:26.6:2.

[0032] 2) Glass fiber cloth loaded TiO 2 :

[0033] The glass fiber cloth loaded with TiO 2 Follow the steps below: a. Soak the glass fiber cloth with a length...

Embodiment 3

[0057] This kind of photocatalyst used in the treatment of microcystins is realized according to the following steps:

[0058] 1) TiO 2 Sol preparation:

[0059] The TiO 2 Preparation of sol: Dissolve 85mL tetrabutyl titanate in 400mL absolute ethanol, add 15mL hydrolysis inhibitor triethanolamine, stir magnetically for 1.5h to make A solution; mix 9mL deionized water and 50mL absolute ethanol, add nitric acid Adjust the pH to 3.0 to make B solution. Slowly add solution B to solution A with magnetic stirring, and continue to stir for 1 hour after the addition is completed to obtain a yellowish transparent sol; the sol is sealed and aged in a dark place for 24 hours for later use; the ratio of each raw material is: n (Cl 2 h 36 o 4 Ti): n (C 4 h 11 NO 2 ) : n (C 2 h 5 OH): n (H 2 (0)=1:0.86:26.6:2.

[0060] 2) Glass fiber cloth loaded TiO 2 :

[0061] The glass fiber cloth loaded with TiO 2 Follow the steps below: a. Soak the glass fiber cloth with a length...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| photodegradation | aaaaa | aaaaa |

| photodegradation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com