Halogen-free expansion type flame-retardant glass fiber reinforced polypropylene material and preparation method thereof

A polypropylene material, intumescent technology, applied in the field of polymer materials, can solve the problems of less influence on PP mechanical properties and processing properties, poor bonding between metal hydroxide and resin, and reduced polymer mechanical properties, etc., to achieve excellent mechanical properties. Good performance, dimensional stability and enhanced mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

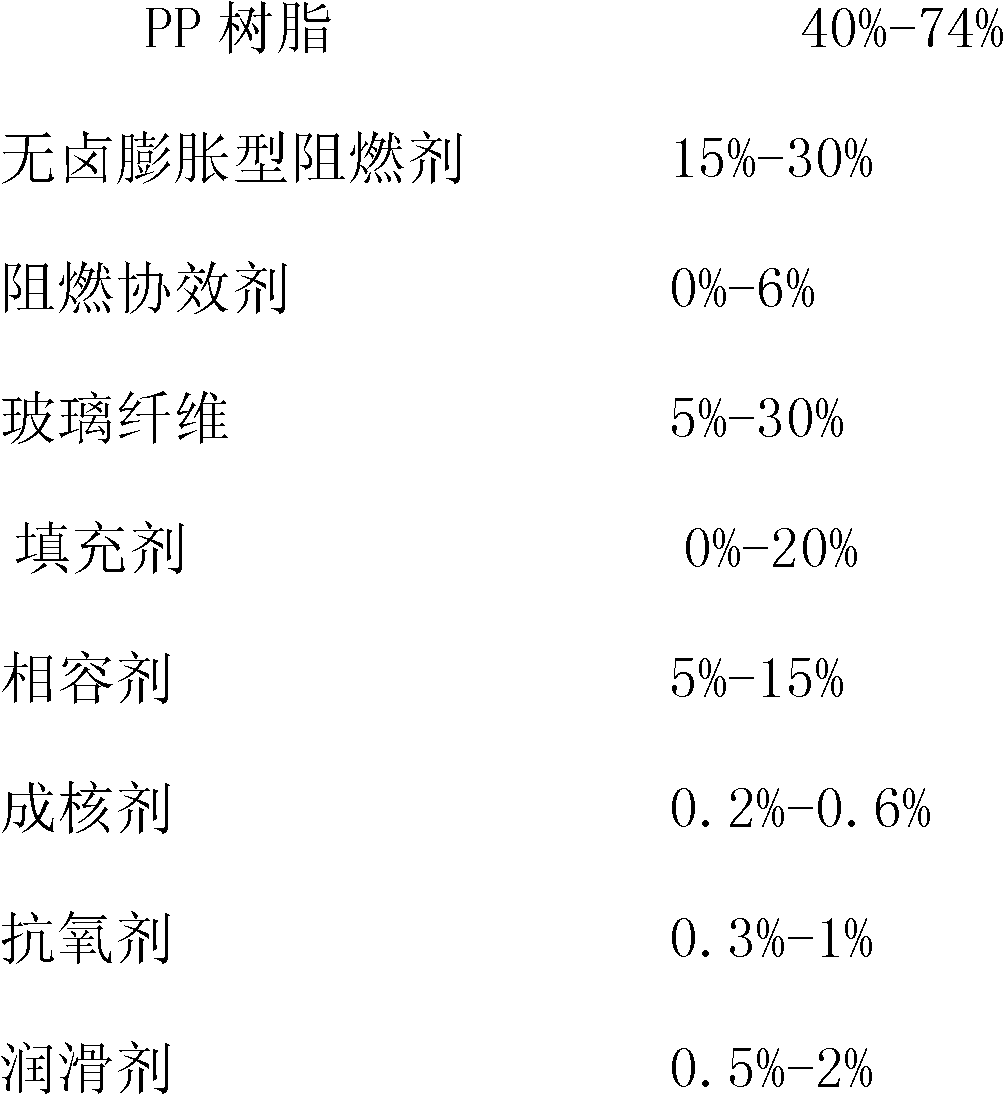

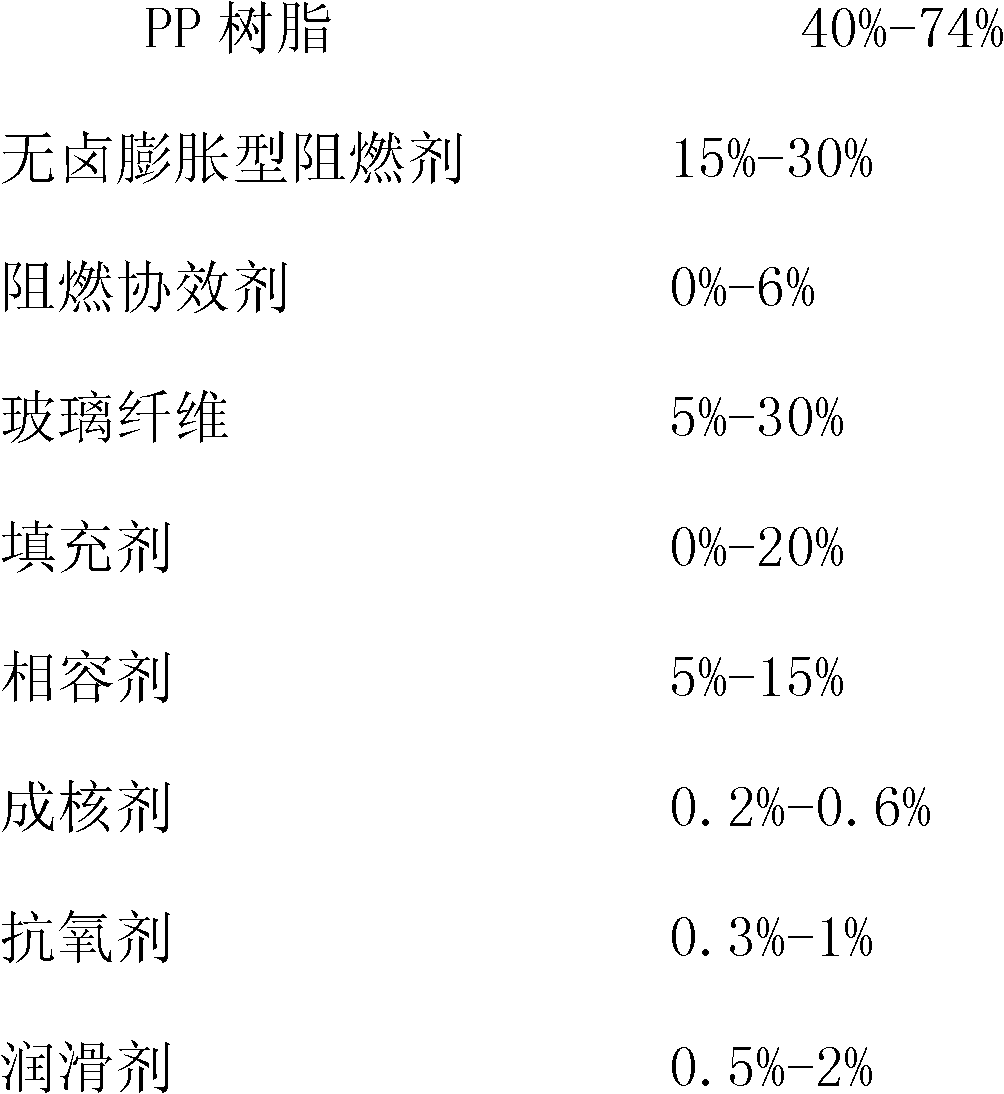

Method used

Image

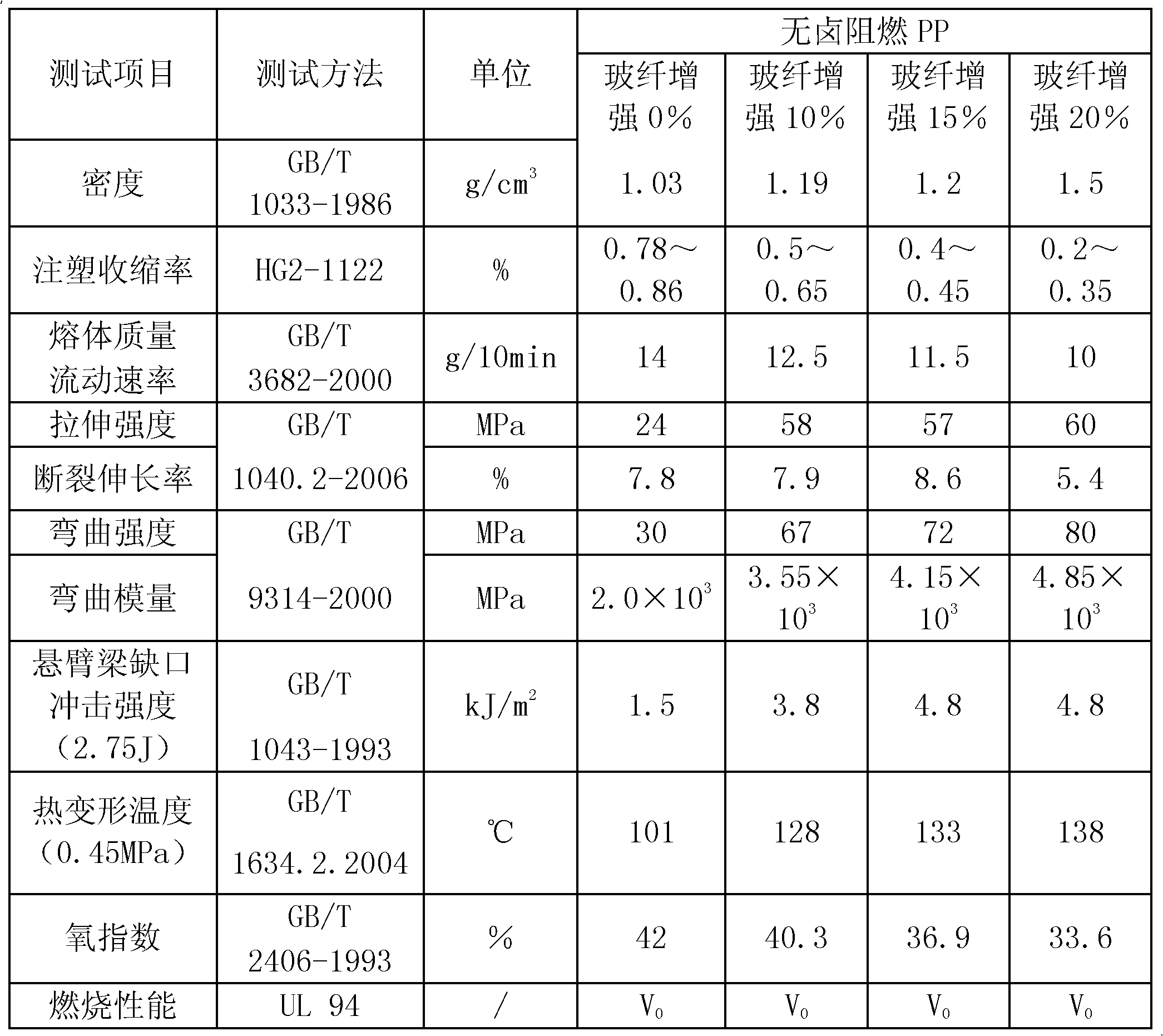

Examples

Embodiment 1

[0032] 1) Put ammonium polyphosphate, melamine and its derivatives, phosphoric acid ester or urea, and triazine oligomer carbon forming agent (mass ratio 15:10:10:5) into a high-speed mixer and mix evenly, then Continue to mix 2% of the coupling agent evenly with the high-speed mixer to compound into a halogen-free flame retardant.

[0033] 2) Weigh PP resin (70%), halogen-free intumescent flame retardant (20%), flame retardant synergist (1%), nucleating agent (0.2%), compatibilizer (8%) by mass percentage ), antioxidant (0.3%), lubricant (0.5%), the above-mentioned components weighed in advance fully mixed in a high-speed mixer.

[0034] 3) The raw materials are placed in a parallel twin-screw extruder for melt extrusion and granulation. The extrusion process is as follows: the temperature of the first zone is 170-190°C; the temperature of the second zone is 170-190°C; the temperature of the third zone is 170°C -190°C; the temperature in the fourth zone is 170-190°C; the tem...

Embodiment 2

[0036] 1) Put ammonium polyphosphate, melamine and its derivatives, phosphoric acid ester or urea, and triazine oligomer carbon forming agent (mass ratio 15:10:10:5) into a high-speed mixer and mix evenly, then Continue to mix 2% of the coupling agent evenly with the high-speed mixer to compound into a halogen-free flame retardant.

[0037] 2) Weigh PP resin (50%), halogen-free intumescent flame retardant (20%), flame retardant synergist (1%), glass fiber (10%), talcum powder (10%), Nucleating agent (0.2%), compatibilizer (8%), antioxidant (0.3%), lubricant (0.5%), the components weighed above are fully mixed in a high-speed mixer in advance.

[0038] 3) The raw materials are placed in a parallel twin-screw extruder for melt extrusion and granulation. The extrusion process is as follows: the temperature of the first zone is 170-190°C; the temperature of the second zone is 170-190°C; the temperature of the third zone is 170°C -190°C; the temperature in the fourth zone is 170-1...

Embodiment 3

[0040] 1) Put ammonium polyphosphate, melamine and its derivatives, phosphoric acid ester or urea, and triazine oligomer carbon forming agent (mass ratio 15:10:10:5) into a high-speed mixer and mix evenly, then Continue to mix 2% of the coupling agent evenly with the high-speed mixer to compound into a halogen-free flame retardant.

[0041] 2) Weigh PP resin (45%), halogen-free flame retardant (20%), flame retardant synergist (1%), glass fiber (15%), talc powder (10%), synthetic Nucleating agent (0.2%), compatibilizer (8%), antioxidant (0.3%), lubricant (0.5%), fully mix the above-mentioned components in a high-speed mixer in advance.

[0042] 3) The raw materials are placed in a parallel twin-screw extruder through melt extrusion and granulation. The extrusion process is:

[0043]The temperature in the first zone is 170-190°C; the temperature in the second zone is 170-190°C; the temperature in the third zone is 170-190°C; the temperature in the fourth zone is 170-190°C; -19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com