Method for synthesizing praseodymium-doped nano titanium dioxide of carbon adsorption tetraisopropyl titanate hydrolysis system

A technology of tetraisopropyl titanate and nano-titanium dioxide is applied in the field of doped nano-titanium dioxide synthesis to achieve the effects of improving thermal stability and crystallinity, reducing sintering and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

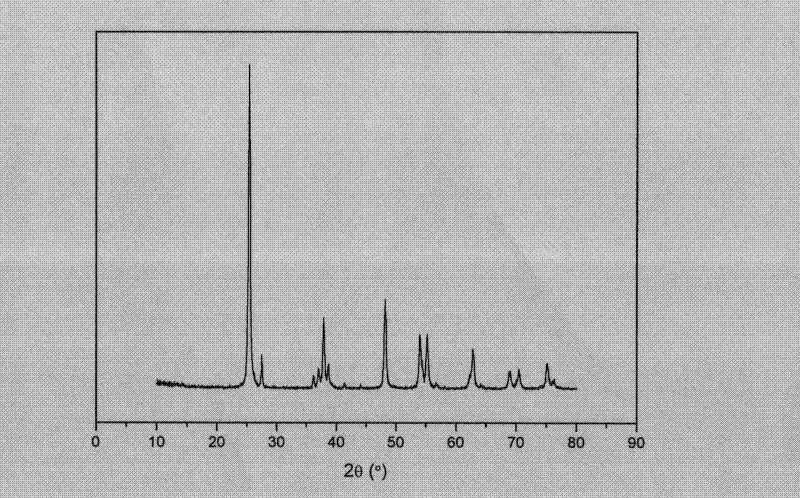

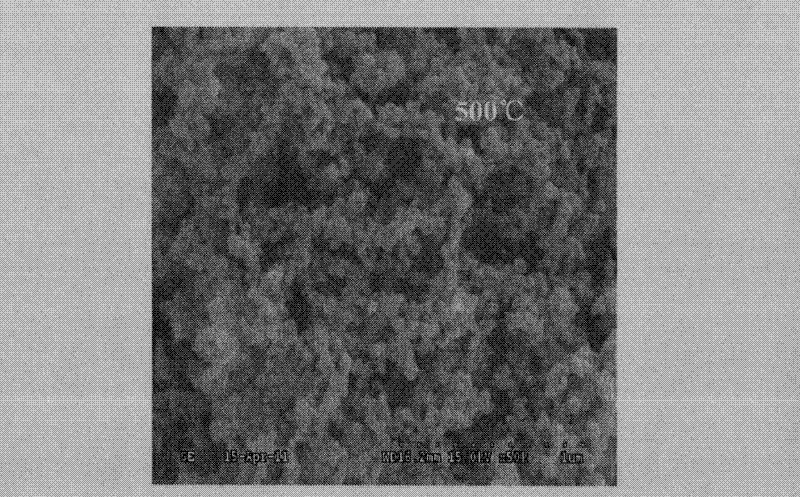

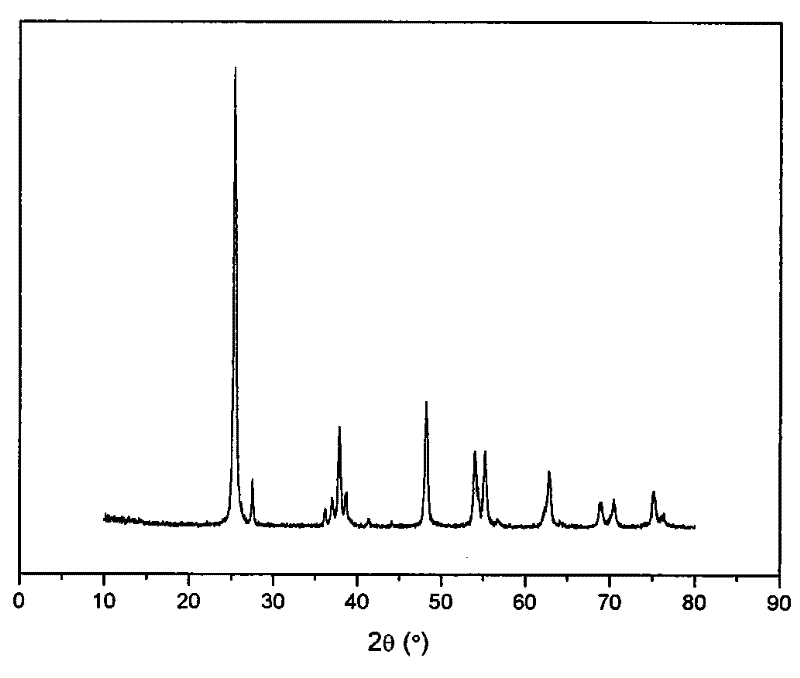

Image

Examples

Embodiment

[0016] Example: Preparation of titanium dioxide powder with a molar ratio of praseodymium and titanium dioxide of 0.07%

[0017] (1) Configure a praseodymium nitrate solution with a concentration of 0.01mol / L, take 2.5g carbon black, mix 1.18ml praseodymium nitrate solution, 8.82ml distilled water and 20ml absolute ethanol, stir and ultrasonically oscillate for 1 hour, adjust with acetic acid, Make the pH value of the system 2 to obtain the mixed system A;

[0018] (2) Take 5ml of tetraisopropyl titanate and 5ml of isopropanol and mix and stir for 10 minutes to obtain solution B;

[0019] (3) Slowly add the solution B dropwise to the mixed system A under the condition of stirring in an ice-water bath. After the dropwise addition, remove the ice-water bath, and seal and stir at room temperature for 6 hours. Then pour it into a polytetrafluoroethylene-lined high-pressure reactor, heat it under magnetic stirring at 150°C for 12 hours, and then cool it to room temperature. The h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com